I tried this over on the DIY forum but didn't have much luck. This might have been the better place to post it.

I currently have a brew stand (which I built) that uses the large BG14 banjo burners. They use a 0-30 PSI adjustable regulator connected to a 20 lb propane tank as a fuel source.

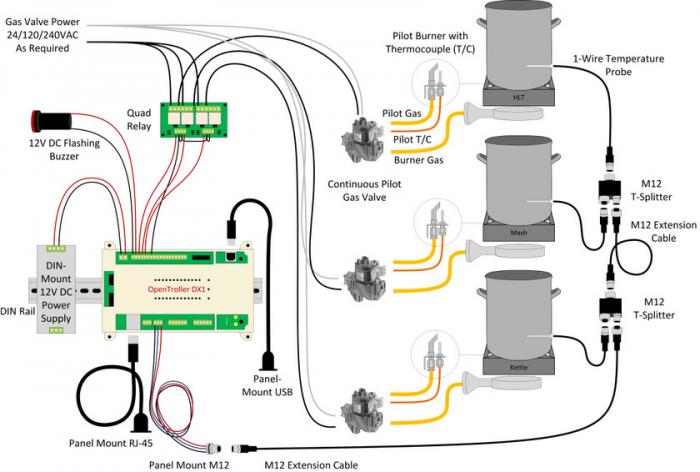

I'd like to look into safely automating a burner.

I am familiar with the various PID controllers (MyPin, Auber, etc.) that are often discussed here. I am not very familiar with gas automation.

So, I have read all I can find and it appears that I am using what is considered "high pressure" propane. It also appears that it is not practical to try to automate a high pressure system. Is this correct?

So, can I buy a different regulator and drill out the burner jets to convert it to low pressure?

If that is possible, can anyone point me at a good source for gas valves that have a thermocouple (to stop gas flow if the burner/pilot blows out) and are capable of lighting themselves (they have an igniter)?

Thanks for any info or pointers on this. I have to run off of standard 20 lb propane tanks as I don't have propane/natural gas at the house. What I'd like to do is automate my HLT.

I currently have a brew stand (which I built) that uses the large BG14 banjo burners. They use a 0-30 PSI adjustable regulator connected to a 20 lb propane tank as a fuel source.

I'd like to look into safely automating a burner.

I am familiar with the various PID controllers (MyPin, Auber, etc.) that are often discussed here. I am not very familiar with gas automation.

So, I have read all I can find and it appears that I am using what is considered "high pressure" propane. It also appears that it is not practical to try to automate a high pressure system. Is this correct?

So, can I buy a different regulator and drill out the burner jets to convert it to low pressure?

If that is possible, can anyone point me at a good source for gas valves that have a thermocouple (to stop gas flow if the burner/pilot blows out) and are capable of lighting themselves (they have an igniter)?

Thanks for any info or pointers on this. I have to run off of standard 20 lb propane tanks as I don't have propane/natural gas at the house. What I'd like to do is automate my HLT.