alowell

Well-Known Member

Hi Guys,

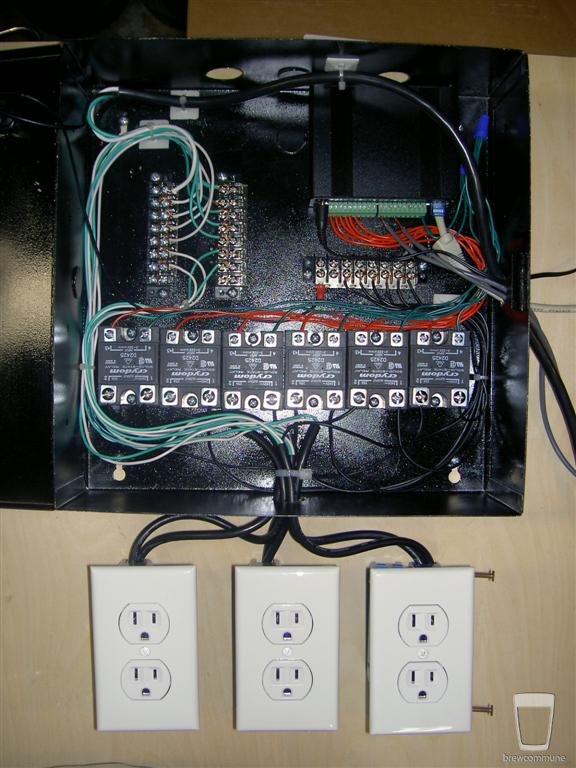

I'm a newbie here and setting up to wire the BCS-460 and my control enclosure. I will be having my electrician friend come over and help me hook everything up, but I am just trying to order parts now. The design I will have is a 120V line coming in off a 30amp circuit. I would like to have a load switch to put the main power onto the enclosure or be able to shut it all down t once. I will have 5 SSRs (running 2 pumps, water heater element, gas solenoid valve, and hot surface ignitor). I will also be putting an outlet in the box for the BCS power supply and a wireless router (if that is needed). I will also have toggle switches (4 of them, On-Off-Auto positions) for the functions (though maybe I need 5 since I cannot combine the ignitor and gas valve into one without spewing gas until the surface get hot enough). Questions:

1. How do I wire the main power to all SSRs. Do I need a strip where the main power line is connected and then is branched off in 6 directions?

2. Do I need a router or is there something smaller that can be plugged into the ethernet port of the bCS-460? I've see little antennas plugged into ethernet ports before.

Thanks, any help would be great. I know the dangers of electrical work and I will not be attempting this on my own, just trying to order some parts now.

Andrew

I'm a newbie here and setting up to wire the BCS-460 and my control enclosure. I will be having my electrician friend come over and help me hook everything up, but I am just trying to order parts now. The design I will have is a 120V line coming in off a 30amp circuit. I would like to have a load switch to put the main power onto the enclosure or be able to shut it all down t once. I will have 5 SSRs (running 2 pumps, water heater element, gas solenoid valve, and hot surface ignitor). I will also be putting an outlet in the box for the BCS power supply and a wireless router (if that is needed). I will also have toggle switches (4 of them, On-Off-Auto positions) for the functions (though maybe I need 5 since I cannot combine the ignitor and gas valve into one without spewing gas until the surface get hot enough). Questions:

1. How do I wire the main power to all SSRs. Do I need a strip where the main power line is connected and then is branched off in 6 directions?

2. Do I need a router or is there something smaller that can be plugged into the ethernet port of the bCS-460? I've see little antennas plugged into ethernet ports before.

Thanks, any help would be great. I know the dangers of electrical work and I will not be attempting this on my own, just trying to order some parts now.

Andrew