FINALLY the FERM build is almost complete. Had to put the build off for a while (started 2/28) waiting for the STC-1000 to arrive from over seas. Finally came in this past Saturday so I got back to finalizing the inside yesterday. Here's a spec list of the build.

Dimensions: 6.5'x30''x2.5' (LxDxH)

Used a Magic Chef mini fridge from Lowe's and a small space heater

Temp Controlle: STC-1000 Dual Stage 110V

Metal Framing, 2'' rigis insulation, spray foam for all interior voids in the metal studs, HVAC foil tape for all joints, FRP for inside finish.

All wiring is completly hidden within the insulation, except where connected to the controler. I put an exterior outlet box on the back of the unit for the power to heater and refer (clipping off the jumper on the hot line connection of the plug). I am attaching the temp prob to the center carboy to access ambient temperature within the chamber (pics will follow).

I think I covered it. Here's some pics of the build. I'll post more once the chamber is 100% complete. Thanks to many of you who post on here for the good info as I used a binch of information from many to plan and complete this build.

Start of Framing:

On to Spray Foam of the metal fram voids:

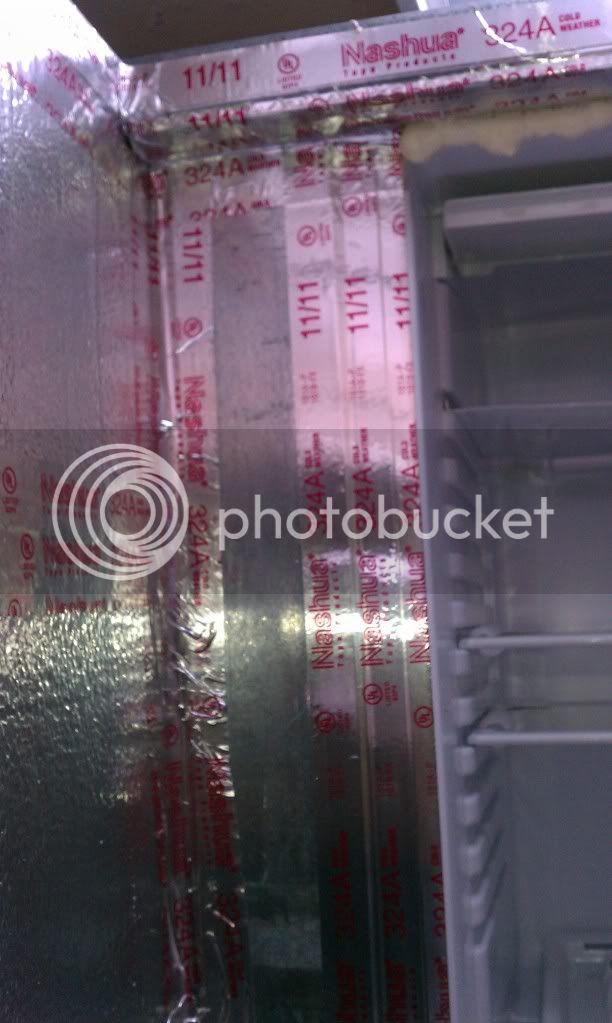

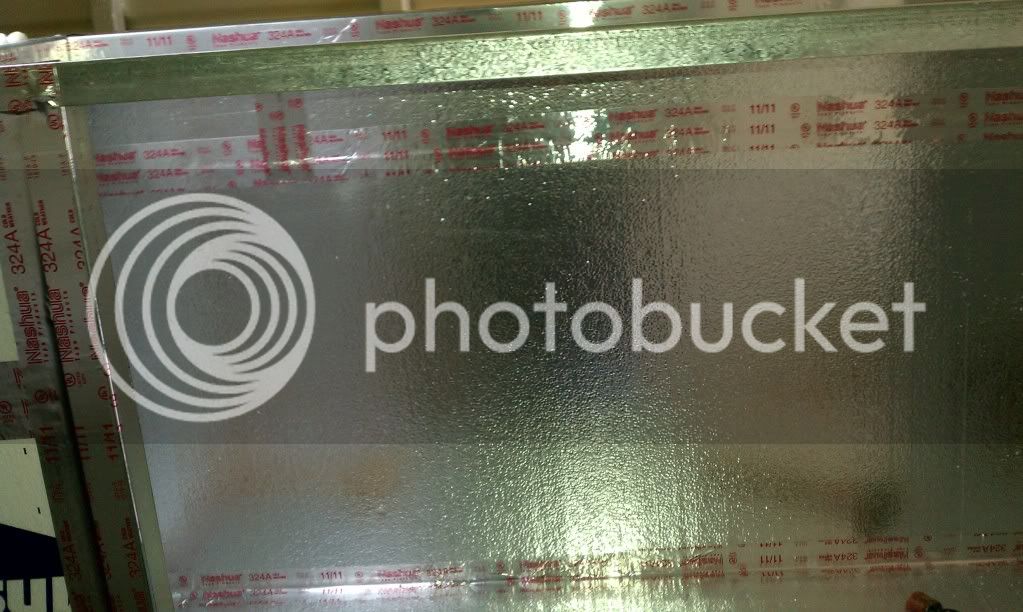

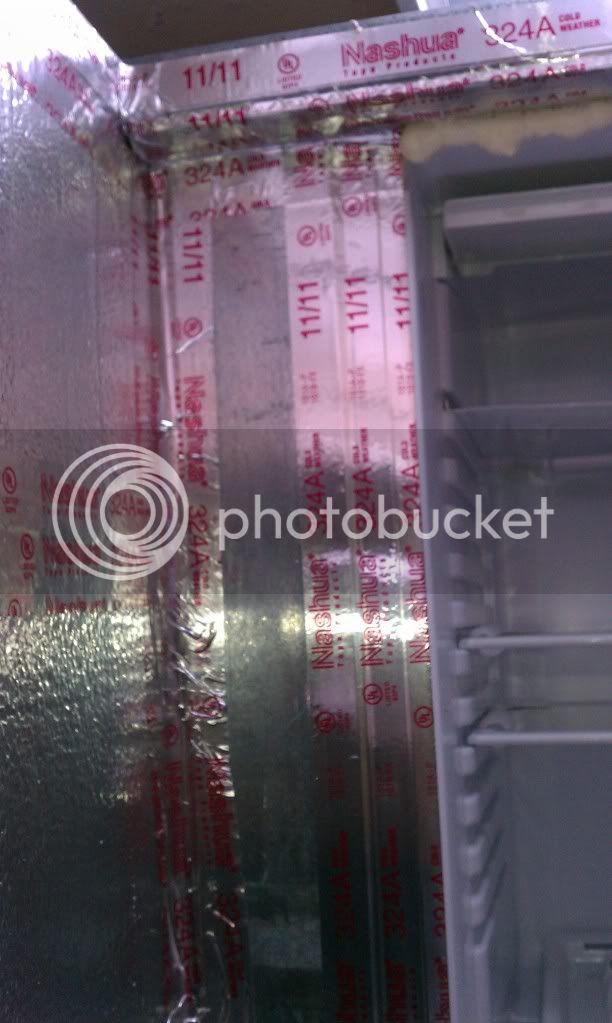

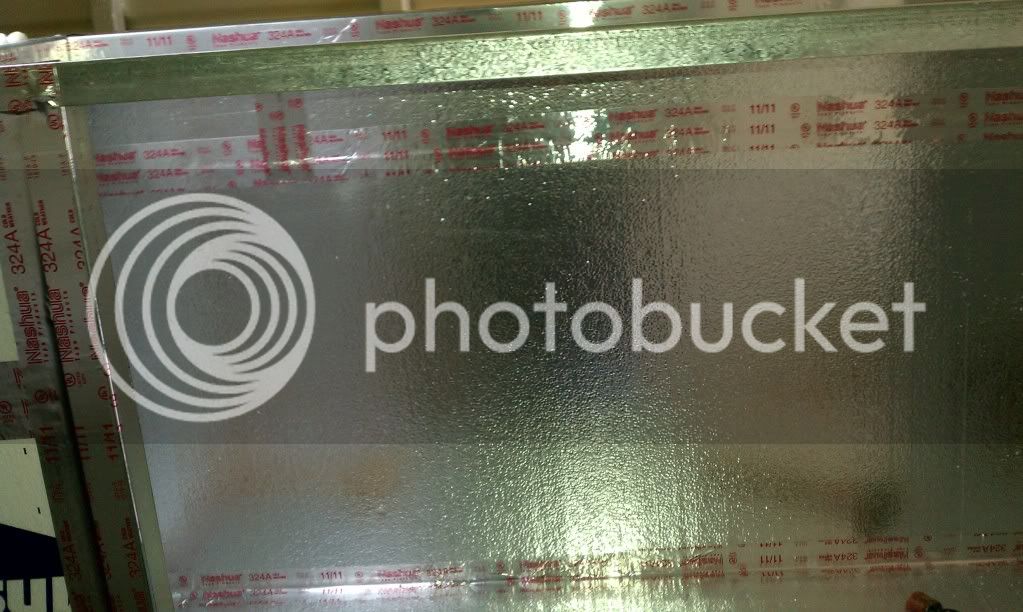

Rigid Insulation Install (1.5'' base w/ full 1/2'' pieces over the 1.5'' to create a total of 2''. All pieces were taped w/ HVAC foil tape)

1/2'' Plywood exterior

Doors (3/4'' Exterior Panel Ply w/ 1/2'' interior panel ply w/ 1.5'' rigid insulation to complete finished off w/ foil tape)

Interior Finish w/ FRP (ceiling/walls/base):

Interior where the STC-1000 is being wired:

More pics to come when complete (which should be Thursday)

Dimensions: 6.5'x30''x2.5' (LxDxH)

Used a Magic Chef mini fridge from Lowe's and a small space heater

Temp Controlle: STC-1000 Dual Stage 110V

Metal Framing, 2'' rigis insulation, spray foam for all interior voids in the metal studs, HVAC foil tape for all joints, FRP for inside finish.

All wiring is completly hidden within the insulation, except where connected to the controler. I put an exterior outlet box on the back of the unit for the power to heater and refer (clipping off the jumper on the hot line connection of the plug). I am attaching the temp prob to the center carboy to access ambient temperature within the chamber (pics will follow).

I think I covered it. Here's some pics of the build. I'll post more once the chamber is 100% complete. Thanks to many of you who post on here for the good info as I used a binch of information from many to plan and complete this build.

Start of Framing:

On to Spray Foam of the metal fram voids:

Rigid Insulation Install (1.5'' base w/ full 1/2'' pieces over the 1.5'' to create a total of 2''. All pieces were taped w/ HVAC foil tape)

1/2'' Plywood exterior

Doors (3/4'' Exterior Panel Ply w/ 1/2'' interior panel ply w/ 1.5'' rigid insulation to complete finished off w/ foil tape)

Interior Finish w/ FRP (ceiling/walls/base):

Interior where the STC-1000 is being wired:

More pics to come when complete (which should be Thursday)