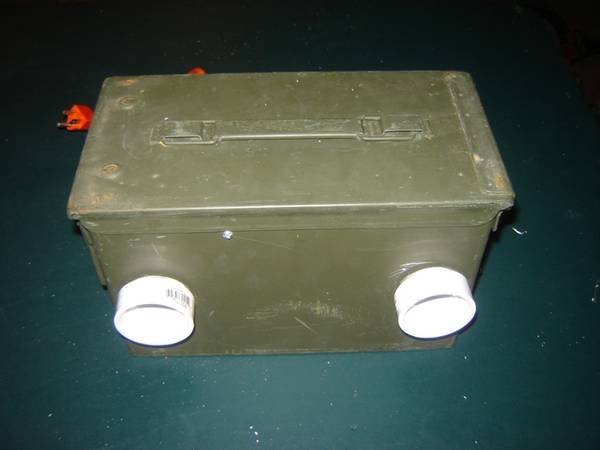

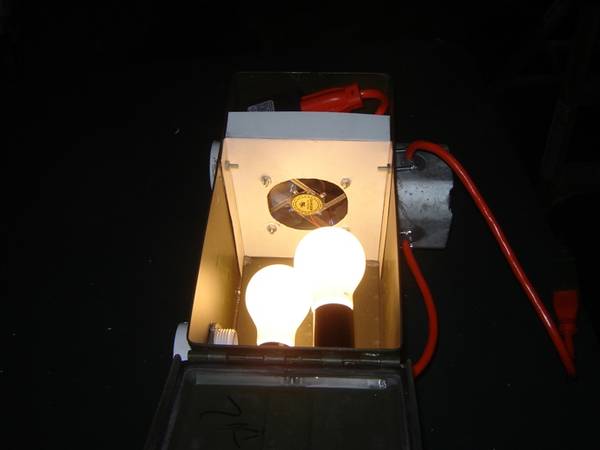

Some of you may have seen my PID controlled brew rig. I built it with a removable control panel so I could use the PID to control my fermentation between brews. Well, I put together a prototype on the cheap. All in all it cost me less than $70 to make (PID control panel not included) Here it is:

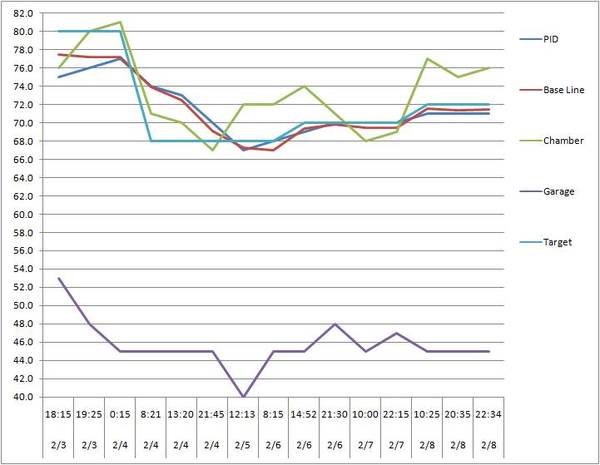

It don't look like much.... but it's holding 20 gal of water @ 68 deg with no problem...

Warm air supply is on the bottom, with the cold air return on the top

you can see the 6 inflow and outflow ports line up between where the 4 carboys sit

she takes up a foot print of about 6 feet by 2 feet

It don't look like much.... but it's holding 20 gal of water @ 68 deg with no problem...

Warm air supply is on the bottom, with the cold air return on the top

you can see the 6 inflow and outflow ports line up between where the 4 carboys sit

she takes up a foot print of about 6 feet by 2 feet