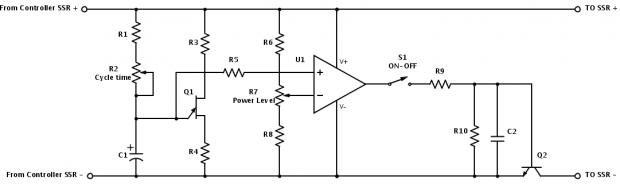

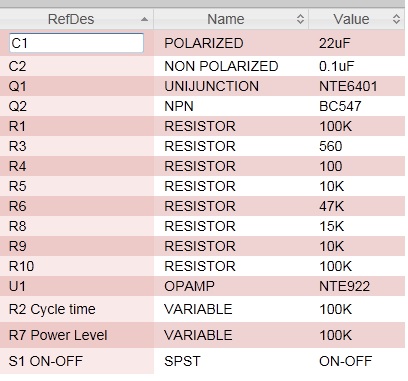

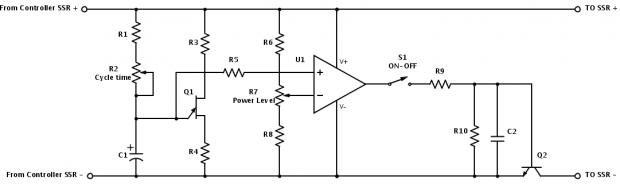

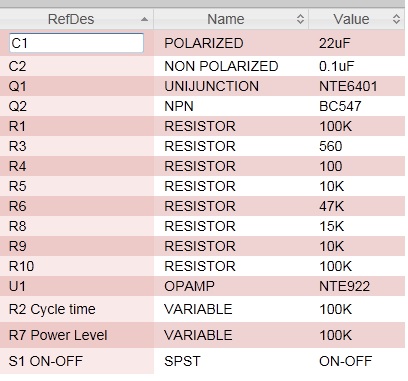

Got started with my electric brewing and yes, bought the temp controller without the manual option to adjust the boil  , so had to come up with this circuit. I know this is out there by the zillions, just wanted to share. You simply install this between your controller and the SSR and let you adjust the power (R7) with PWM from about 10% to full power. The control cycle is adjusted by R2. The on/off switch is optional, you could modify R6 from 47K to about 39K or 27K and lower your minimum power from 10 to 0%.

, so had to come up with this circuit. I know this is out there by the zillions, just wanted to share. You simply install this between your controller and the SSR and let you adjust the power (R7) with PWM from about 10% to full power. The control cycle is adjusted by R2. The on/off switch is optional, you could modify R6 from 47K to about 39K or 27K and lower your minimum power from 10 to 0%.