mosquitocontrol

Well-Known Member

Okay, right now I'm deciding between a gravity fed system and one with a pump. Trying to get the full cost on the table so I can make a real decision. The problem is, I got way confused when looking into camlocks.

Trying to make a 3 vessel system (2 keggles and a cooler). Using one pump that I can hook/unhook between the 3 vessels.

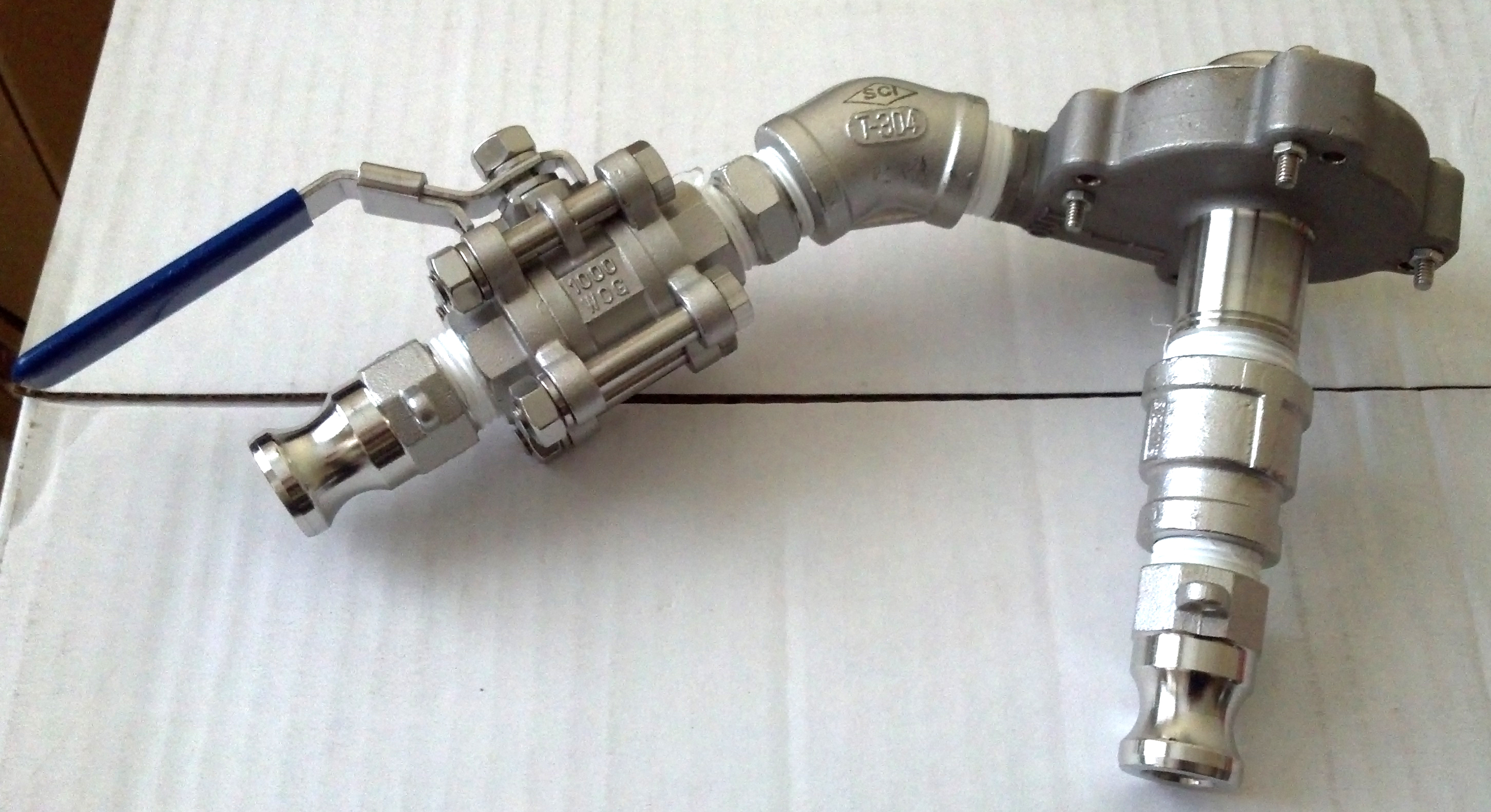

I was going to get 3-piece ball valves on the output of all vessels. After that, I was confused. I looked at the graphic on brewhardware and it seemed like it was saying to put another valve on the pump? That didn't seem right.

What pieces would I need to do this:

ball valve outlet on keggle (can hook/unhook) --> silicon tubing --> chugger pump ---> silicon tubing --> input on other keggle/cooler/counterflow chiller, etc.

Trying to make a 3 vessel system (2 keggles and a cooler). Using one pump that I can hook/unhook between the 3 vessels.

I was going to get 3-piece ball valves on the output of all vessels. After that, I was confused. I looked at the graphic on brewhardware and it seemed like it was saying to put another valve on the pump? That didn't seem right.

What pieces would I need to do this:

ball valve outlet on keggle (can hook/unhook) --> silicon tubing --> chugger pump ---> silicon tubing --> input on other keggle/cooler/counterflow chiller, etc.