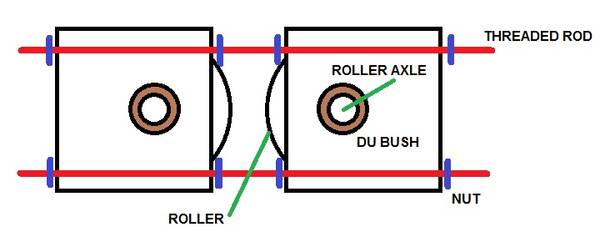

I got a tiny bit of spare cash and I wanted to get a mill. Over here a corona style will set you back $100+ so I thought I would look into getting a roller mill fabricated by a workshop I know through work. Now I want to make it a simple as possible and have come up with this concept.

The end blocks will be drilled through for the threaded rod and held in place by the nuts (gap setting by them aswell). Will get a 1 or 2 mm sheet metal base made to give it a bit more stability and this will overhang the mill a bit to also allow it to be bolted down to a board.

Any ideas, comments, questions or suggestions?

The end blocks will be drilled through for the threaded rod and held in place by the nuts (gap setting by them aswell). Will get a 1 or 2 mm sheet metal base made to give it a bit more stability and this will overhang the mill a bit to also allow it to be bolted down to a board.

Any ideas, comments, questions or suggestions?