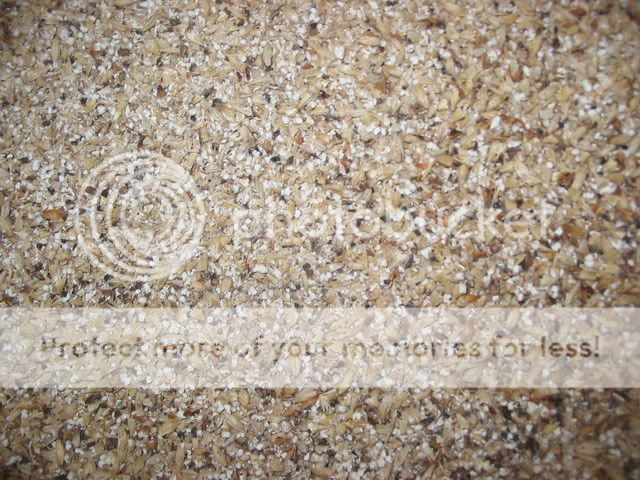

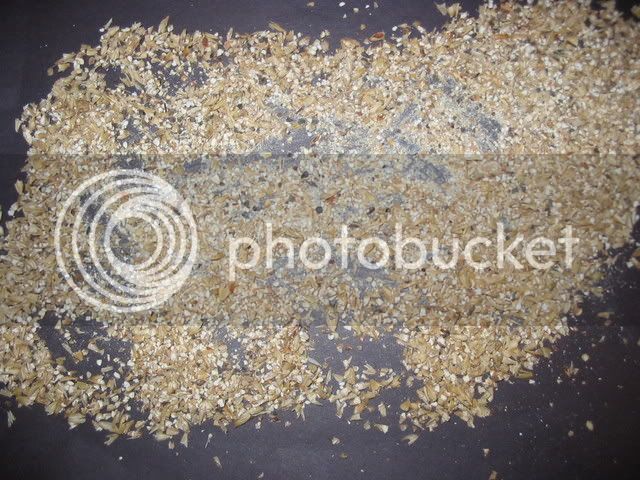

What I noticed with my mill is that the kernels get crushed, but a lot of them remain still inside the husk. Unless the husks are actually shed from the kernel, it's almost impossible to extract the sugars. I typically run my grain through a second time and this finishes the job and actually separates the kernel from the husk. This is the principle behind the 3 roller mills that some places sell.

Is this the exact same grain you were using before? Same malster? Same batch? If the gravity potential of the grain falls even just a few points and you don't account for it in your recipe, your efficiency will appear to significantly change. It may appear like your efficiency went down, but in reality, everything is exactly the same. For instance, if you count on the grain giving you 37 PPG and your normal efficiency is 75%, but you get a new batch of grain that only gives 34 PPG and you don't change anything else, it will appear as though your efficiency fell by 6%. Just a thought.

Prosit!