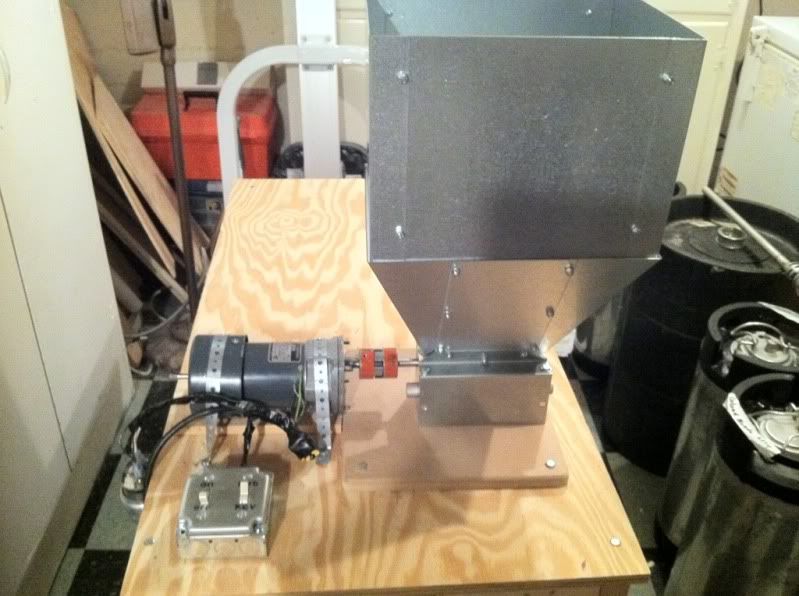

I have a 3 three roller monster mill. I have it mounted and motorized, but I can't figure out a good way to set the gap.

I know the top rollers are fixed. I have a feeler gauge, but I have 2 questions:

1) Which rollers do put the feeler gauge between? The motorized roller and the bottom roller? Or the non-motorized roller and the bottom roller.

2) How do you do this? With the side plates, hopper and mounted to the table it seems impossible. Even unmounted it seems very awkward to say the least.

Are you supposed to remove the hopper and the side plates to set the gap with a feeler gauge? This seems like a lot of work just to adjust the gap, no?

Any help is greatly appreciated. I'm stumped.

I know the top rollers are fixed. I have a feeler gauge, but I have 2 questions:

1) Which rollers do put the feeler gauge between? The motorized roller and the bottom roller? Or the non-motorized roller and the bottom roller.

2) How do you do this? With the side plates, hopper and mounted to the table it seems impossible. Even unmounted it seems very awkward to say the least.

Are you supposed to remove the hopper and the side plates to set the gap with a feeler gauge? This seems like a lot of work just to adjust the gap, no?

Any help is greatly appreciated. I'm stumped.