dutchoven

Well-Known Member

Im in the process of moving to all-grain and have been fabbing up a new brew kettle, MLT, and HLT from kegs. I recently cut my kegs and built a custom false bottom

thought Id post my progress so far.

First, the keg cutting

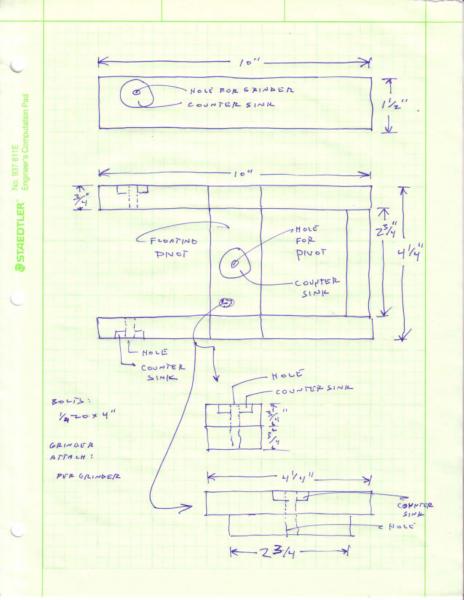

To cut the kegs, I built a jig out of 1x2 wood stock and fit it to a 4 angle grinder. The jig mounts to the grinder handle attachments and pivots off the keg opening. All told, the jig took me about 45 minutes to build and cost around seven bucks. Yeah, probably overkill, but it helped me get really nice cuts

In building the jig, I wanted something that could be adjusted to different cutting diameters. To do this, I let the pivot point of the jig float in the jig, adjusted by a bolt installed in the back of the jig. Once I set my desired diameter (12 for the keg openings), I screwed everything into place.

At the pivot point, I used another bolt to adjust the height of the jig and angle of the blade this helped maintain the cut-off wheel at 90 degrees to the keg top.

First, the keg cutting

To cut the kegs, I built a jig out of 1x2 wood stock and fit it to a 4 angle grinder. The jig mounts to the grinder handle attachments and pivots off the keg opening. All told, the jig took me about 45 minutes to build and cost around seven bucks. Yeah, probably overkill, but it helped me get really nice cuts

In building the jig, I wanted something that could be adjusted to different cutting diameters. To do this, I let the pivot point of the jig float in the jig, adjusted by a bolt installed in the back of the jig. Once I set my desired diameter (12 for the keg openings), I screwed everything into place.

At the pivot point, I used another bolt to adjust the height of the jig and angle of the blade this helped maintain the cut-off wheel at 90 degrees to the keg top.