So I did my first brew on this rig about 2 weeks ago. I decided to do a 10gal batch of a simple blond ale (23lbs Pale 2-row, 1lb crystal, 2oz Willamette). I ran into a few snags but otherwise a pretty successful brew day and it seems I have beer in the fermenter.

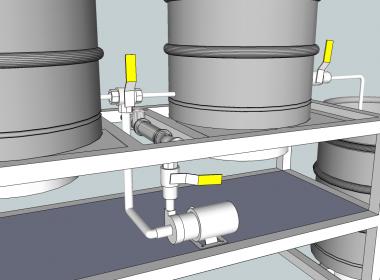

First off I couldn't get my PID to recognize the RTD probe from my RIMS tube (turns out there was a loose wire that needed to be re-soldered), so I decided to just direct fire my MLT while circulating during the mash. The dough-in went fine, but I think my thermometer probe on the MLT is off by 7-10 degrees (and I couldn't get to that damn adjustment screw while it was clamped on). Halfway through the mash, my RIMS pump overheated and shut down. At the time I chalked it up to the MLT burner throwing some heat down that way which shouldn't be a problem once my RIMS tube is working correctly. Anyway, we just shut off the gas and let the pump cool down. Temps were fairly consistent, but with the thermometer inaccuracies, I don't have a clue how close I was to my target.

Either way, we made it to sparge with no other problems. I foolishly turned off the burner on my HLT when I hit sparge temp and it lost about 15* during the sparge. Lesson learned there. I'm pumping my sparge water through the RIMS tube, so I suppose I could use the heating element to help maintain that temp as well. Unfortunately the dang pump overheated again during sparge, despite the MLT burner being off. The only thing I could figure was that the splash guard was not allowing enough air to circulate around the pump fan, so I took it off and put a ziplock full of ice over the pump housing. It cooled off quickly and we proceeded to sparge. I vastly under estimated my losses due to grain absorption, so I had to heat up another few gallons to reach my target (12 gallons).

Despite all those hiccups I managed to hit my pre-boil gravity pretty close to goal. I think I was about 70% on my mash efficiency. I'll be more careful with my measurements once I get this thing running more smoothly so I can get a better idea of what my efficiencies are.

Boil, chilling and pitching all went off without a hitch.

There was only one other issue: I used a 'contractor grade' 6.5hp wet-vac I picked up from Lowes to suck my spent grain out of my MLT and the damn hose collapsed. I don't know if it was a combination of the heat and the thickness or what. I'm going to take the thing back and get another one (still under warrenty).

After I got the RTD and PID working correctly a few days later, I ran the RIMS tube/pump for about an hour at 140* without any trouble from the pump. So I think I'll leave the splash guard off during brew days and only put it back on during cleaning to prevent any major spills. There are additional splash guards on the top tier which should catch any small spills during brew days.