SavageBrewer

Well-Known Member

- Joined

- Jun 20, 2012

- Messages

- 56

- Reaction score

- 7

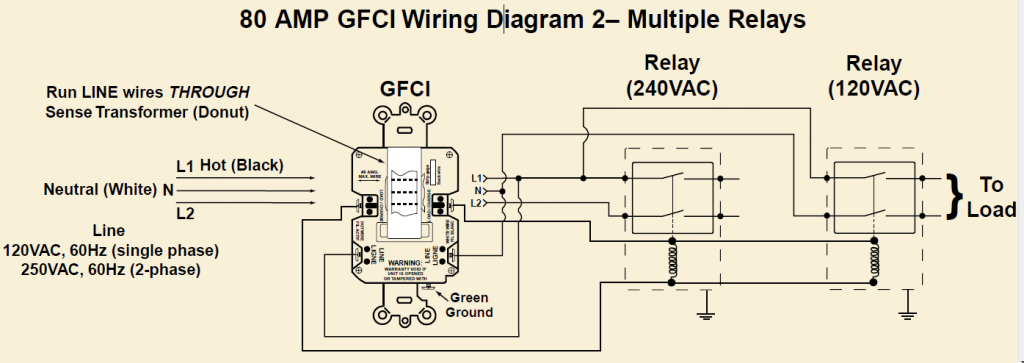

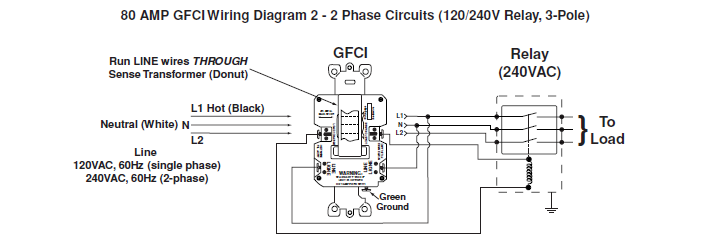

While searching for gfi breakers for my system I came across this link.

http://www.spadepot.com/shop/GFCI-High-Current-Donut-P9733C193.aspx

Has anybody tried to use this as a panel mounted gfci? If so, how hard is it to wire up in the enclosure? My enclosure is finished and I was wondering how much work it would be to wire one of these in. . Just looking for some insight.

http://www.spadepot.com/shop/GFCI-High-Current-Donut-P9733C193.aspx

Has anybody tried to use this as a panel mounted gfci? If so, how hard is it to wire up in the enclosure? My enclosure is finished and I was wondering how much work it would be to wire one of these in. . Just looking for some insight.