Like the title says, I'd like to go electric. Tired of getting propane and with summer coming I'd like to get away from the heat that propane brings with it. I do want to do this as cheap as possible though. I'm thinking of using my current 36 quart stainless pot as an HLT (refilling and reheating additional water after mash in as needed), a cooler for my MLT, and buying a keg to make a keggle. I want to use one 5500 watt heating element in the HLT and one in the keggle. I don't care to automate temp control since the cooler won't lose much heat over the course of a one hour mash. If I can use a rheostat in place of a PID temp controller then I would like to go that way, unless the rheostat is somewhat close in price to the PID controller. I don't think I would need to regulate the element in the HLT since I can just turn it off once I hit the temp I need. So I think I would only need to regulate the element in the keggle to control the boil.

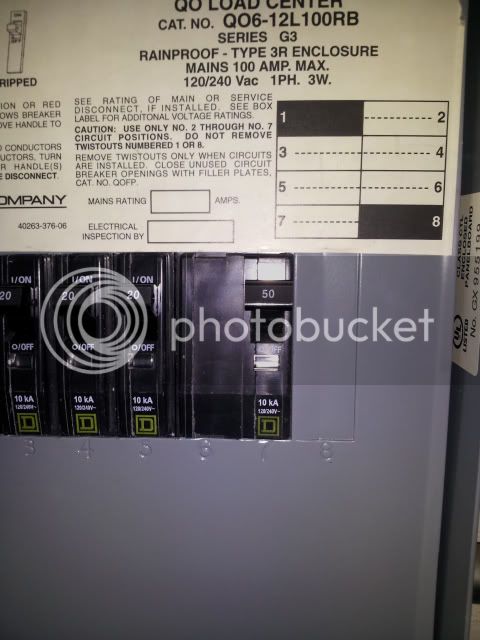

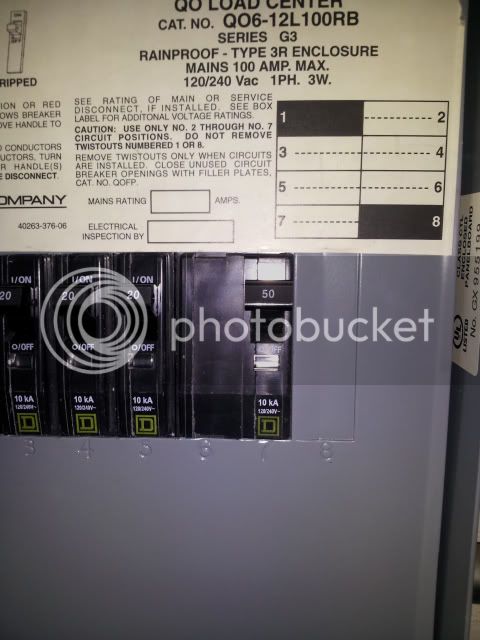

I used to build custom motorcycles and had a large TIG welder so I already have a 240v 50 watt panel in my garage. Here are pictures of what my electricity supply looks like:

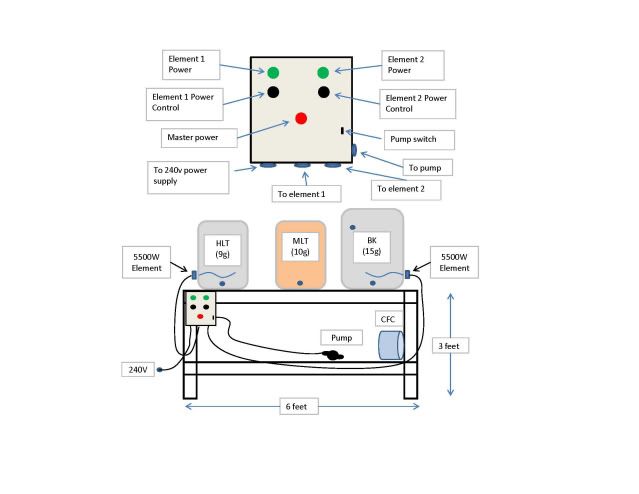

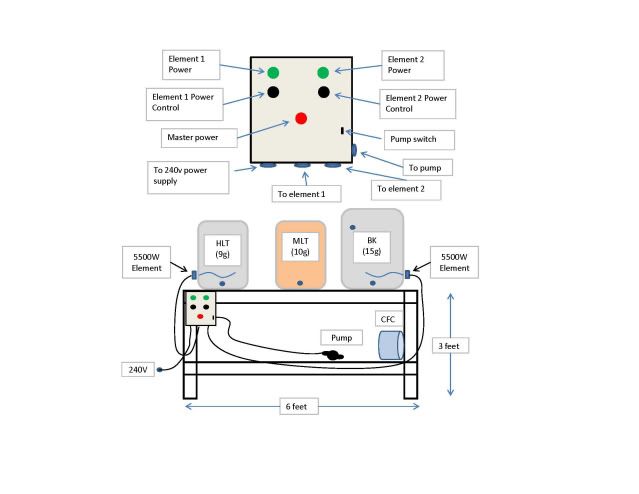

And this is a sketch I made of what I would like my setup to look like. On my sketch of the control panel I have a controller for the HLT element but I don't think I'll need it.

My plan is to just use one pump to move liquid, changing connections as needed.

I've been looking through quite a few of the build threads but I don't think I've seen any that use a rheostat to control the power on the elements. I appreciate any input on whether or not my ideas will work and possibly a list of what components I will need.

Here are a couple of questions I've come up with so far:

Can I use a rheostat to control the power to the elements?

Does it hurt the elements to have the power received reduced?

Will I need a heat sink in my control panel?

Do I need a spa panel or is what I have already taking care of that?

Thanks all!

I used to build custom motorcycles and had a large TIG welder so I already have a 240v 50 watt panel in my garage. Here are pictures of what my electricity supply looks like:

And this is a sketch I made of what I would like my setup to look like. On my sketch of the control panel I have a controller for the HLT element but I don't think I'll need it.

My plan is to just use one pump to move liquid, changing connections as needed.

I've been looking through quite a few of the build threads but I don't think I've seen any that use a rheostat to control the power on the elements. I appreciate any input on whether or not my ideas will work and possibly a list of what components I will need.

Here are a couple of questions I've come up with so far:

Can I use a rheostat to control the power to the elements?

Does it hurt the elements to have the power received reduced?

Will I need a heat sink in my control panel?

Do I need a spa panel or is what I have already taking care of that?

Thanks all!