WPStrassburg

Well-Known Member

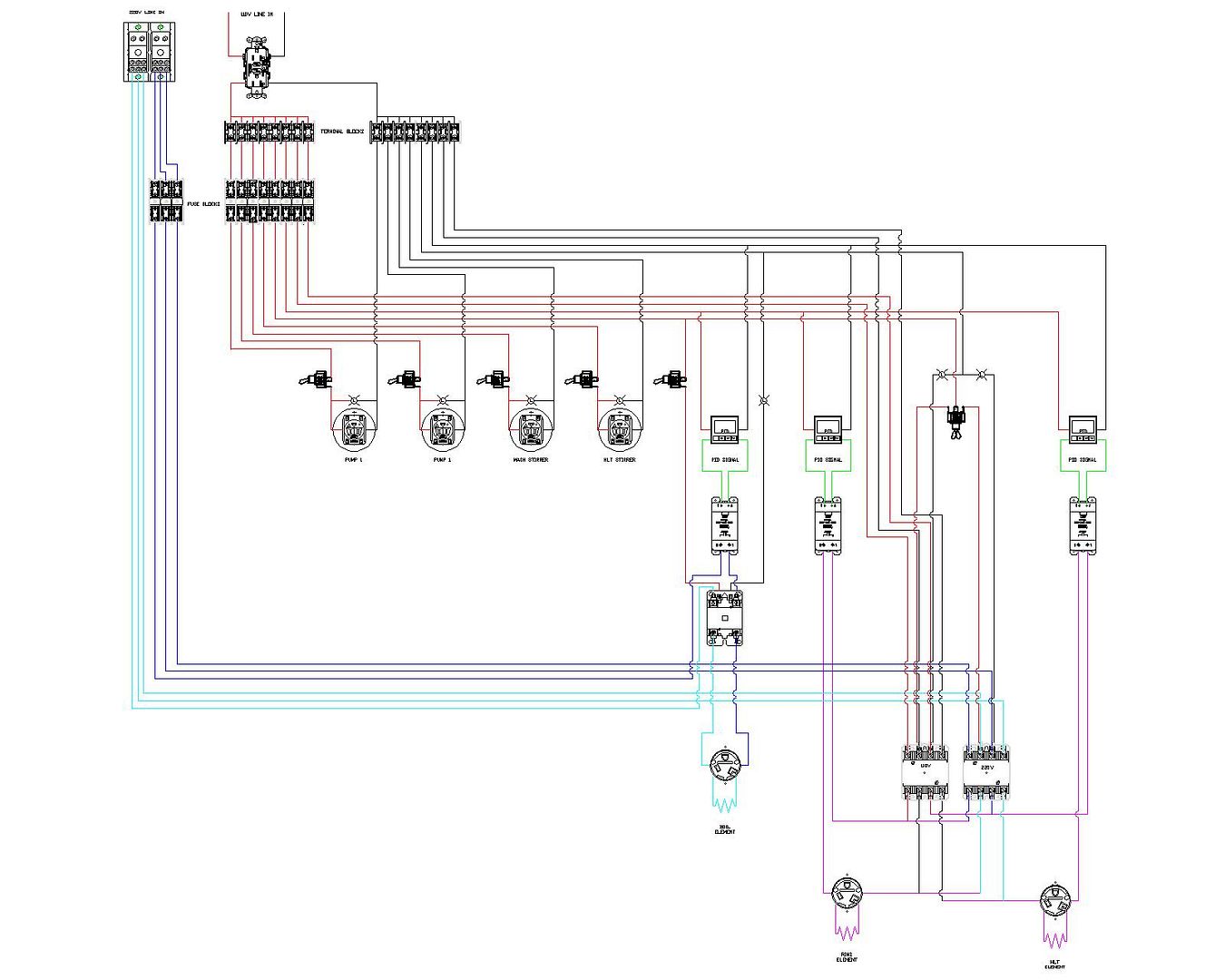

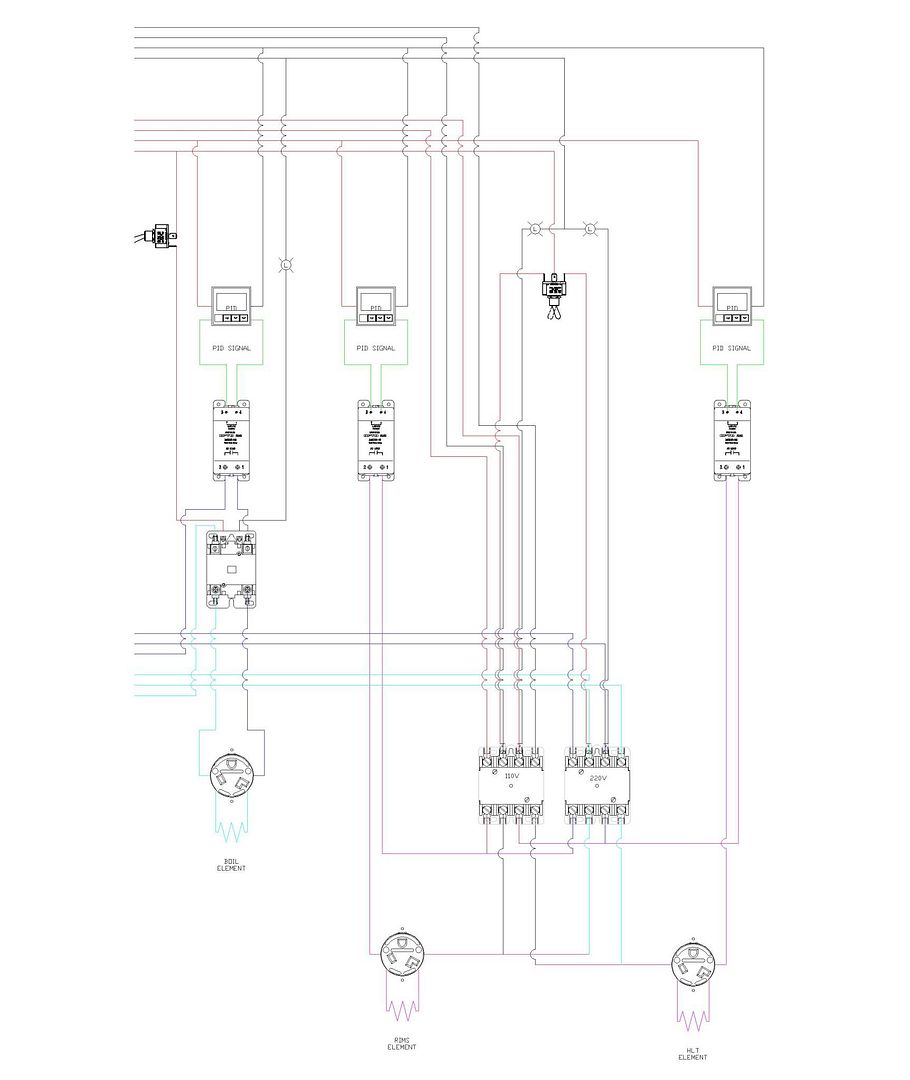

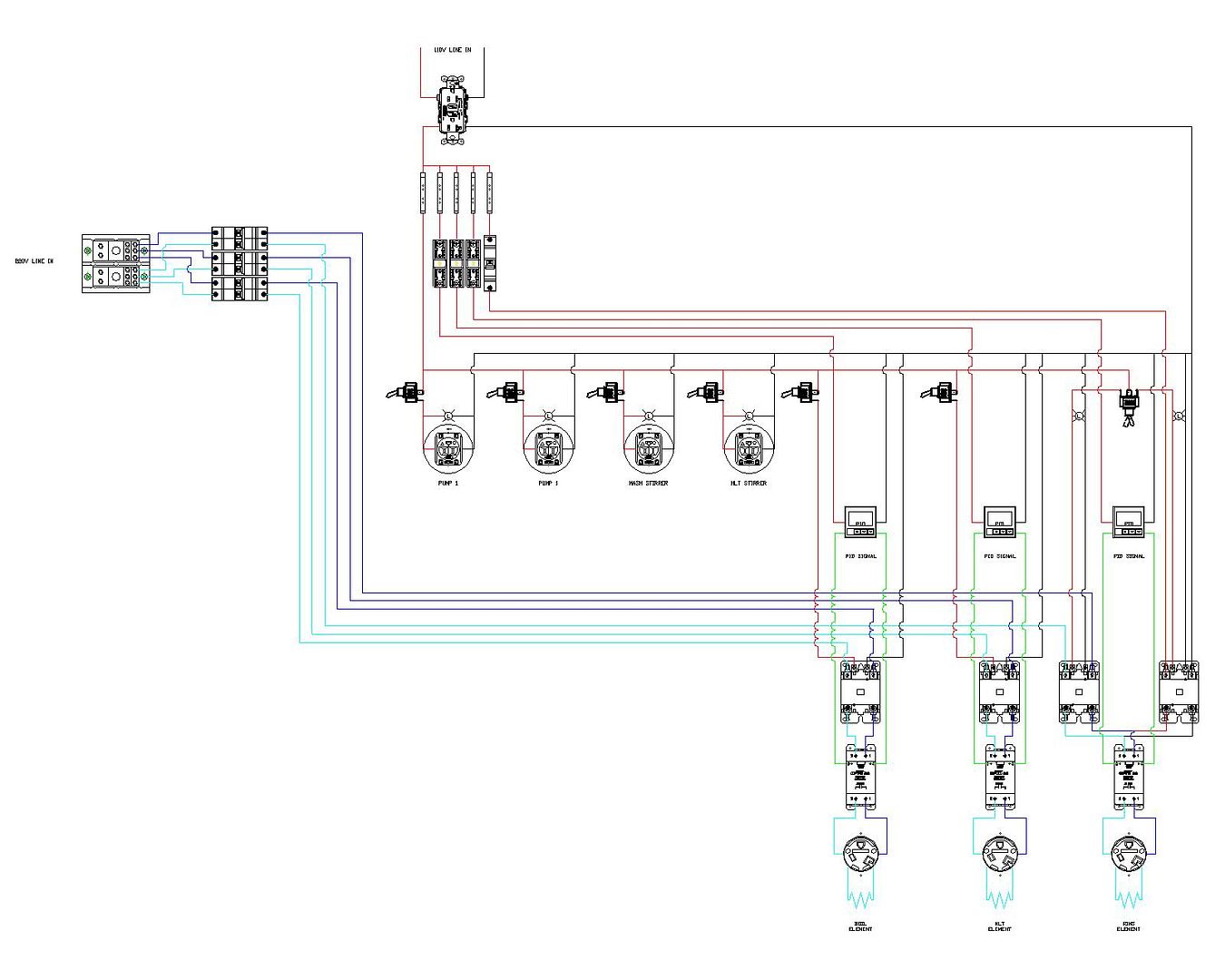

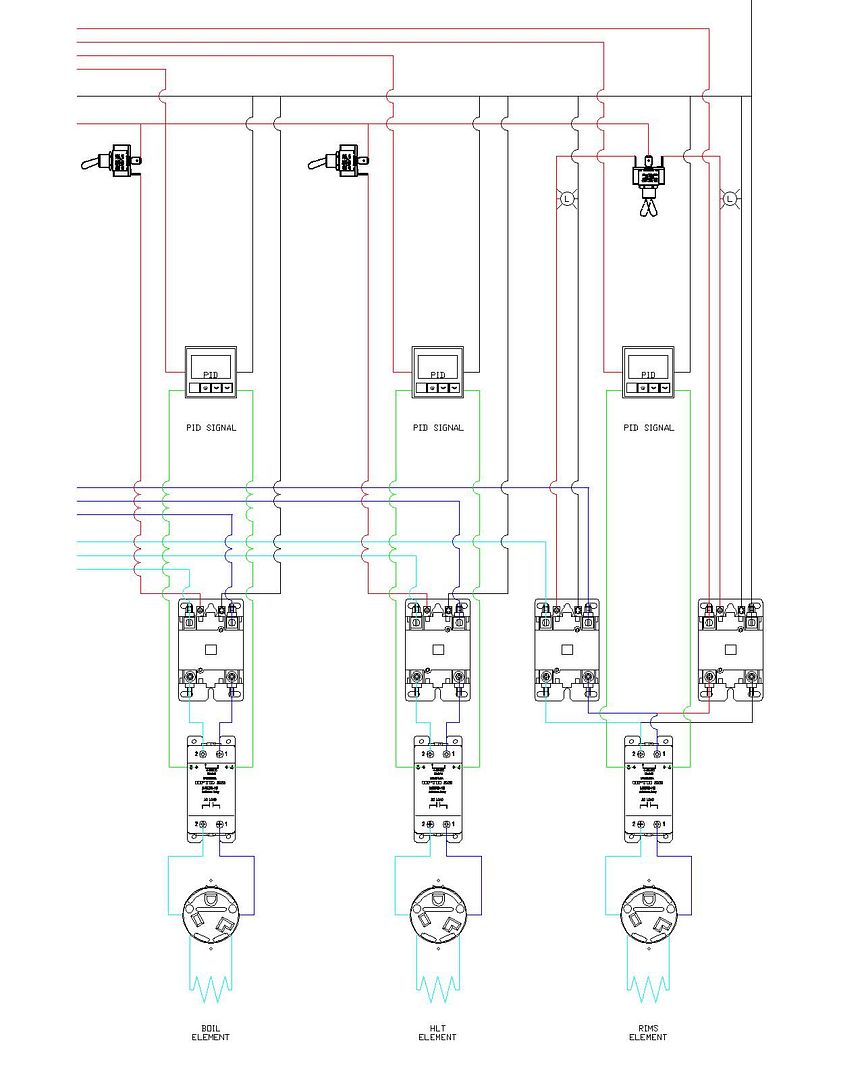

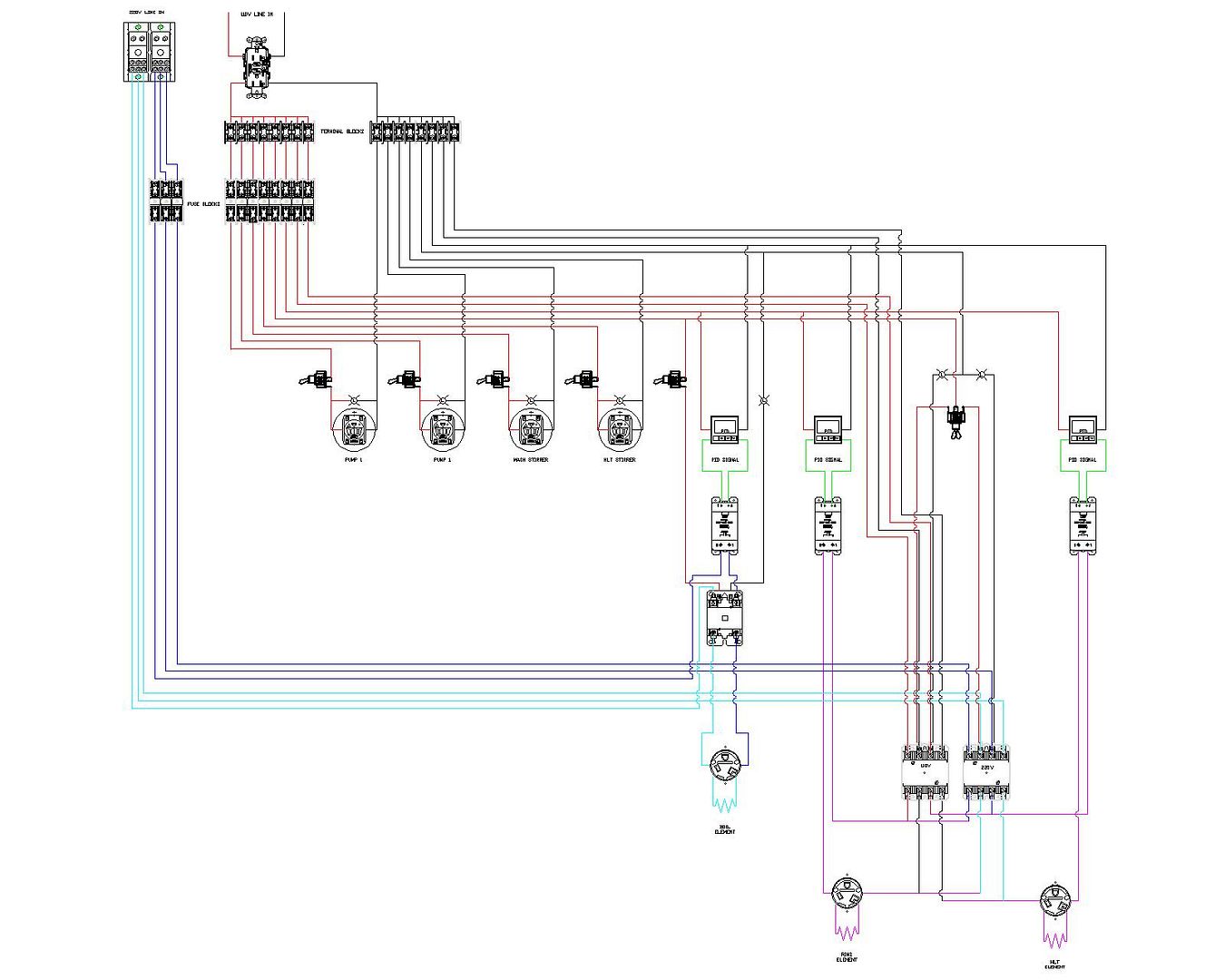

I've been working on getting a schematic together for my control panel and think I'm getting pretty close, but I'd like some commentary. I'm doing a basic manual control for my system to switch 2 pumps, 2 gearmotor stirrers for the hlt and mash tun, a 220v 5-6kw boil element, a rims element, and a hlt element. For the rims and hlt I'd like to be able to switch the power between 110v and 220v so I can brew on 220v in the basement during the winter and then outside on NG with 110v rims and hlt control. The thought is that if I can switch between 110/220 I can control the elements with 2 pid's instead of 4. I currently have two 4 pole contactors to switch between 110 and 220 via a 3-way, center off, switch. All the 110 power will be through a gfci receptacle and the 220 will be through a 50A gfi breaker. I'm trying to stay flexible, but not complicate the panel too much. Thoughts and comments please.

Thanks,

Walter

Thanks,

Walter