There is a possibility I might be venturing down the road of commercial brewing. I have several people who are urging me to go pro and want to help. I am putting together a team of people to possible open a small brewery and tasting bar in my home town. So far I have two people who are pushing me to do this.

My roommate is a lawyer. He wants to be involved and is super excited to see something like this happen. He will take care of all the forms and regulations that need to be followed. He will be the dot the I's and cross the T's guy.

My other friend is an Idea/marketing type guy. He has a ton of experience in another industry. He was a brand manager and field ambassador for an outdoors company. He is also very capable of providing the funding needed to start out.

I of course would be the brewer and the guy who can make the whole thing work from technical aspect.

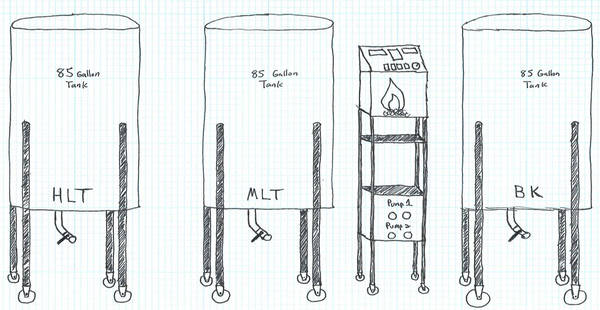

My question to those of you who have done this. What size system should I be looking at? Should I build it or should I buy it?

We will be looking for a small space to brew beer for catering companies and also have a small walk-in bar for people to session some beer locally. There is a small brewery in Ouray colorado that will be the model for our business. The Ourayle House. There capacity I think is 1.5 barrels. They only brew beer for the taps that are at their bar. They serve no food. You can only get their beer.

So this is a plan we are working on and would love some input on equipment from the folks here. I know a few of you have started nano breweries, you have been inspiring me for several months now.

My roommate is a lawyer. He wants to be involved and is super excited to see something like this happen. He will take care of all the forms and regulations that need to be followed. He will be the dot the I's and cross the T's guy.

My other friend is an Idea/marketing type guy. He has a ton of experience in another industry. He was a brand manager and field ambassador for an outdoors company. He is also very capable of providing the funding needed to start out.

I of course would be the brewer and the guy who can make the whole thing work from technical aspect.

My question to those of you who have done this. What size system should I be looking at? Should I build it or should I buy it?

We will be looking for a small space to brew beer for catering companies and also have a small walk-in bar for people to session some beer locally. There is a small brewery in Ouray colorado that will be the model for our business. The Ourayle House. There capacity I think is 1.5 barrels. They only brew beer for the taps that are at their bar. They serve no food. You can only get their beer.

So this is a plan we are working on and would love some input on equipment from the folks here. I know a few of you have started nano breweries, you have been inspiring me for several months now.