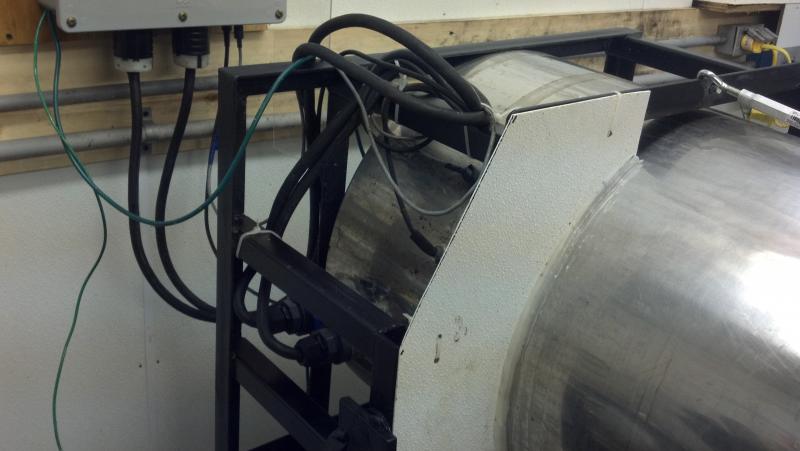

Ran the first run today with the new rig. It all worked very well

See the you tube video

[ame=http://youtu.be/UZi_FmmHpJU]Squam Brewing New setup - YouTube[/ame]

See the you tube video

[ame=http://youtu.be/UZi_FmmHpJU]Squam Brewing New setup - YouTube[/ame]