PuckeredPenguin

Well-Known Member

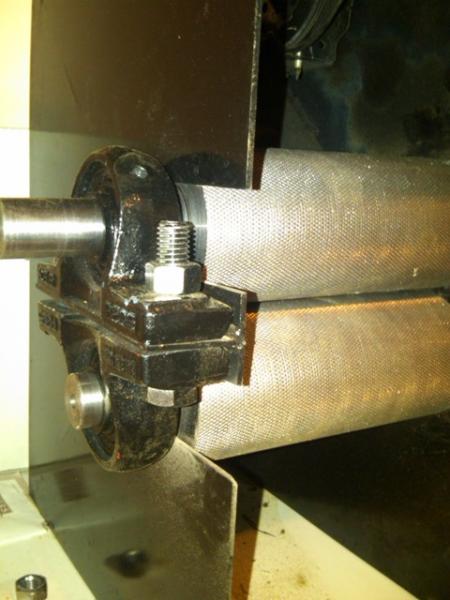

Here is the link http://www.harborfreight.com/compact-2-speed-1-2-half-inch-right-angle-drill-97622.html

It's two speed 340/1375 I run it at 340 with no problems.

It's two speed 340/1375 I run it at 340 with no problems.