Hi all,

I'm planning on using this element: http://www.amazon.com/dp/B0002YU2YS/?tag=skimlinks_replacement-20

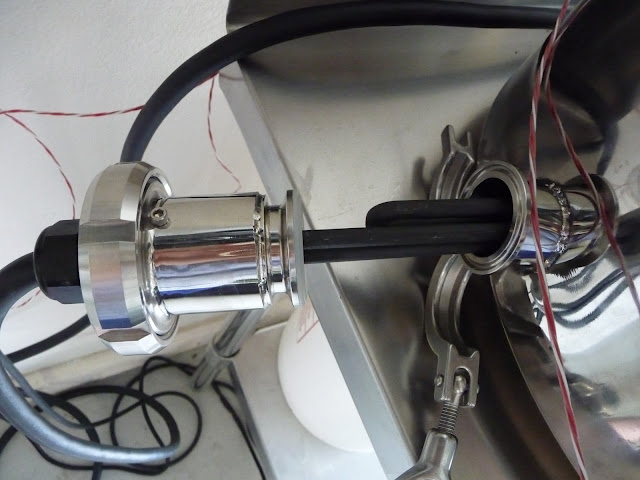

With this fitting: http://www.brewershardware.com/TC15F10NPSCOV.html

or: http://www.brewershardware.com/2-Tri-Clover-X-1-NPS-Element-Adapter.html

or: http://www.hillbillystills.com/Heating_Element_plate_p/hecp.htm

1) Does anyone know if I need a short ferrule or can I use a long one?

2) Does the short ferrule get in the way of removing the tri clamp?

3) Will the element hit the side wall of the pot with a short ferrule?

3) Do you have a recommendation for which tri clamp x NPT fitting to use?

Thanks!

I'm planning on using this element: http://www.amazon.com/dp/B0002YU2YS/?tag=skimlinks_replacement-20

With this fitting: http://www.brewershardware.com/TC15F10NPSCOV.html

or: http://www.brewershardware.com/2-Tri-Clover-X-1-NPS-Element-Adapter.html

or: http://www.hillbillystills.com/Heating_Element_plate_p/hecp.htm

1) Does anyone know if I need a short ferrule or can I use a long one?

2) Does the short ferrule get in the way of removing the tri clamp?

3) Will the element hit the side wall of the pot with a short ferrule?

3) Do you have a recommendation for which tri clamp x NPT fitting to use?

Thanks!

Last edited by a moderator: