All:

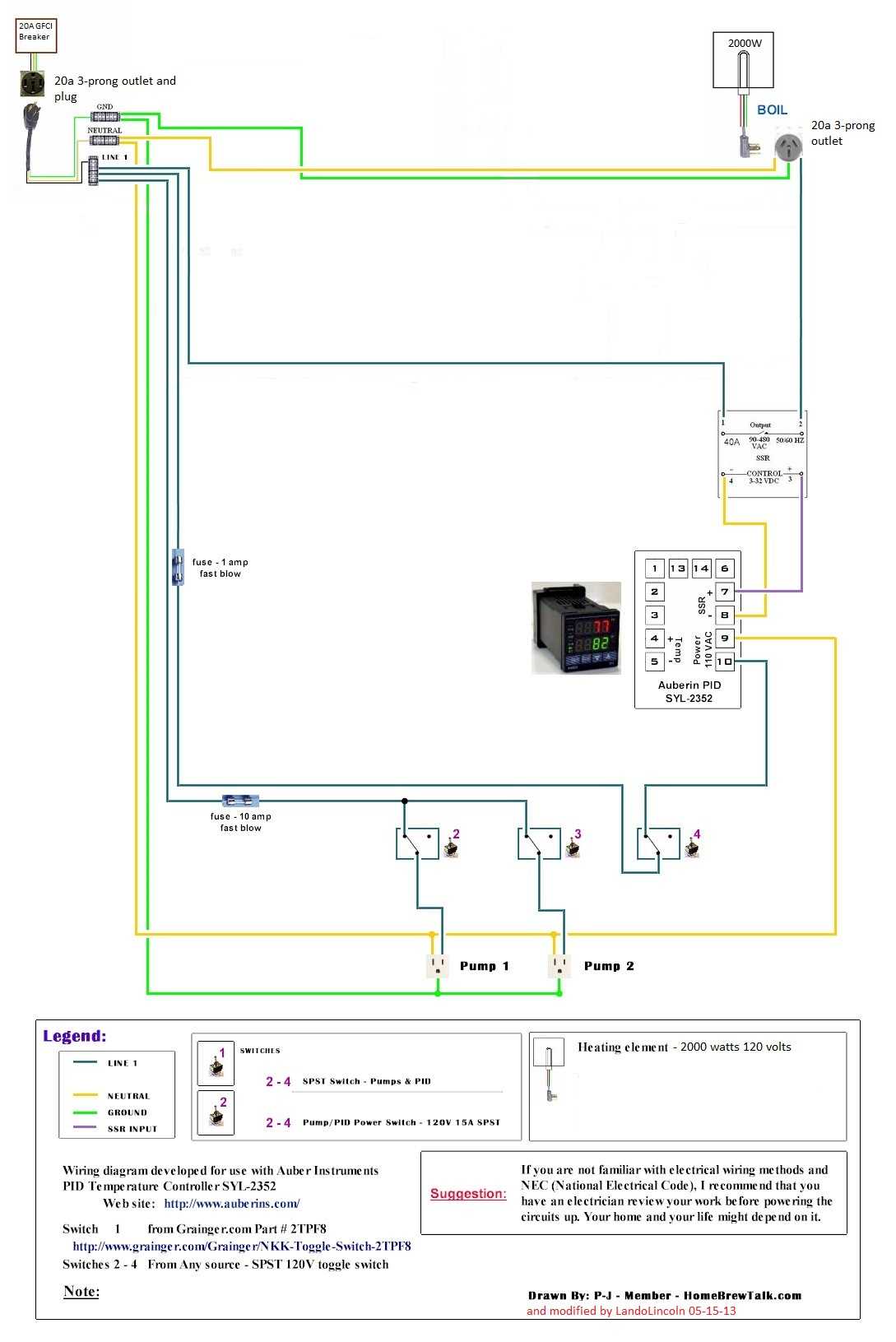

I'm in the planning stages of a hybrid electric/propane HERMS system. My system would include only one heating element around 1500 to 2000W. The rest would be propane.

I need a control panel that will include space for one PID controller for the element and two on/off switches for two pumps that I plan on incorporating. I thought I might build this, but I don't really have the know-how. Is there a commercial vendor who sells something like this at a reasonable price? I checked out "high gravity's" panels, but they are more than I need and the price is kinda high.

I'm in the planning stages of a hybrid electric/propane HERMS system. My system would include only one heating element around 1500 to 2000W. The rest would be propane.

I need a control panel that will include space for one PID controller for the element and two on/off switches for two pumps that I plan on incorporating. I thought I might build this, but I don't really have the know-how. Is there a commercial vendor who sells something like this at a reasonable price? I checked out "high gravity's" panels, but they are more than I need and the price is kinda high.