Johnnyrhine

Active Member

What you you have at the bottom of your tun? Why? If you've used both which worked better?

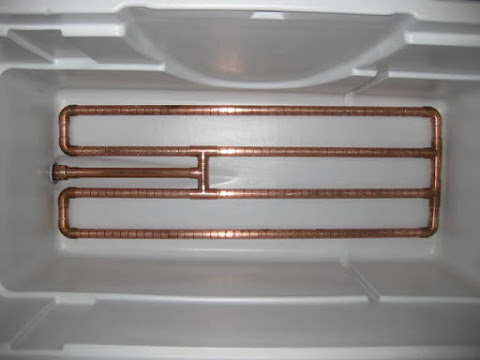

I have a manifold. My attempts at making a false bottom failed miserably so making a manifold was the only option.

I have a manifold. My attempts at making a false bottom failed miserably so making a manifold was the only option.