I'm kinda new at AG, and I 1st did the SS braid, as it was the easy way to get into it.

That being said, After my 2 nd mashing I knew I wasn't getting all of my liquid out of my 48 qt. cooler. I had to tilt one end up with 2 2x4's to almost drain completely.

On my cooler, the drain was about 1 1/4" - 1 1/2" above the bottom.

It left over a gallon of wort if I didn't tilt it. Thats quit a bit.

So I read about the mash tun manifolds on the How to Brew website and others.

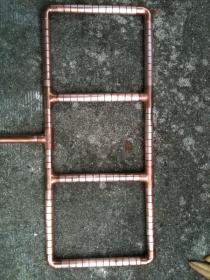

I decided to go with the CPVC material. It's very easy to work with, and everybody will have the tools to make one with this material. This is what I came up with below.

BTW, As Plamer says, in How to Brew, a good spacing for the manifold is 2" - 4" apart,Closer is better. The "T's" and "90's" CPVC parts I used, will give you a spacing of 2" apart , when touching one another. The long pipes , the ONLY ones that have slits @ 1/4" apart and 1/3 deep.I cut the slits with a Japanese pull saw. I used another "T" and another "90" to connect to the drain. Took me about an hour and a half, Start to finish.

After I cut and assembled it, I did some water tests to SEE with my own eyes, how it would work. I did the same with the SS braid, and could see since the drain was higher, it would leave a lot of water in the bottom after draining, and HAD to TILT IT UP, to get ALMOST all outa it. But not , nowhere all of it. Still left alot in there.

With the CPVC and a 3/8" HOSE put on the 3/8" valve outside the cooler. I added 3 gallons of water. Started the draining , and watched the water go down fast. I thought once the water level got to the bottom of the drain (that is 1 1`/2" above the bottom) that it would stop. It didn't. I went right down to the bottom floor of the cooler. It only left 12 oz of water. Like not even an 1/8" on the bottom.

Poured the 3 gallons of water back into the cooler, and removed the 3/8" hose from the valve. Opened it up, and to my surprise, Much, Much SLOWER. way slower, and the water stopped right at the drain.

I just learned what the hose does. The hose acts to siphon and really SUCK the liquid out. With my drain being 1 1/2" higher!

In MHO, If your drain is not flush with, OR very close to the bottom of your cooler, I think your better off with some kinda manifold rather than a SS Braid.

Reason why I'm writing this is, I hope it helps other Starter Outers like my self. Hopefully , this can clear some "NOT KNOWINGS" up.

BTW, I know all of the more experienced brewers here, will already have all of this knowledge!!! LOL

Anyone can message me if ya want more info.