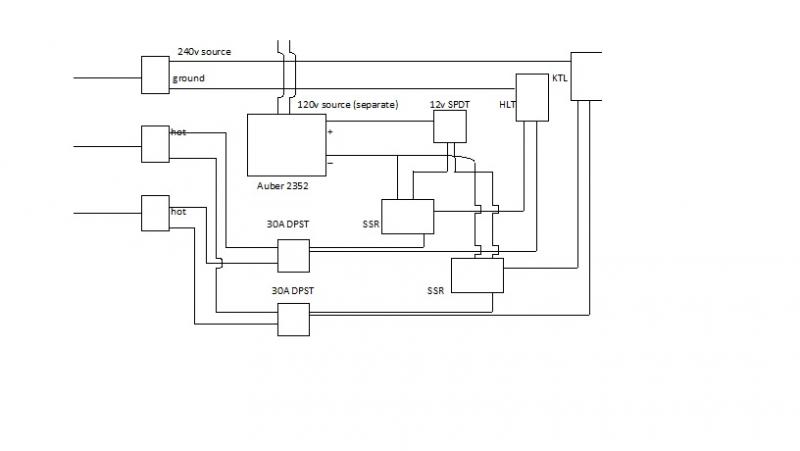

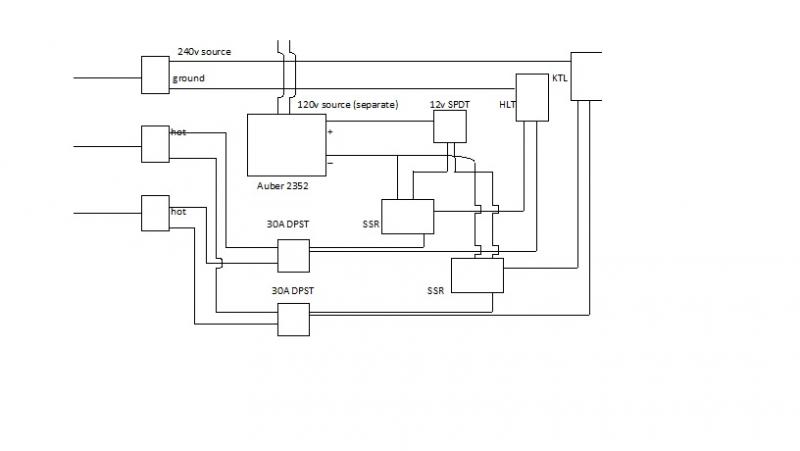

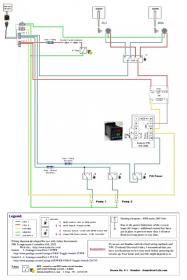

I am attempting to wire my kettle and HLT to one PID. Unfortunately I have only 3-wire 240v source so I am relying on a separate 120v source to power the PID. Any comments or suggestions on how to improve this simple design would be appreciated. The 12v dc spdt switch should allow me to switch between driving the kettle ssr and the hlt ssr. The PID is an auber 2352 and I plan to use manual control on the kettle and the hlt will have an rtd probe.