Ok. Ive been lurking and looking at everyones brew stand bling for too long.

I've gone over every permutation and combination of brewing system there is:

1 vs 2 vs 3 vessel, 1 vs 2 vs 3 tier, BIAB, HERMS, RIMS, driving myself crazy trying to design the AG system best suited to my needs. This is what I've finally come up with.

I don't have a lot of cash to throw at this, so first, the system has to be relatively inexpensive. But I want to be able to tweak, add and improve upon it as I develop my brewing skills and as I can afford it.

I want to keep the equipment list as short as possible. I love the simplicity of BIAB. So I started to think about a 1 vessel system. I like the idea of full volume mashing and can live with the loss of efficiency, but Im not crazy about lifting and transferring grain in a bag. So Ill need to incorporate a mash tun.

I love Lonnie's Brutus 2.0 concept as a method of keeping a mash tun in the equation:

http://www.alenuts.com/Alenuts/brutus20.html

I have an igloo cooler MLT so I wanted to use this in my system. The things I don't like about the Brutus 20 are the need to use 2 pumps and 2 burners.

I love jkarp's countertop Brutus 20:

https://www.homebrewtalk.com/f51/countertop-brutus-20-a-131411

It solves the two pump, two burner problem, but I don't want to use electricity and I want to be able to ramp this thing up to eventually do 10 gallon batches.

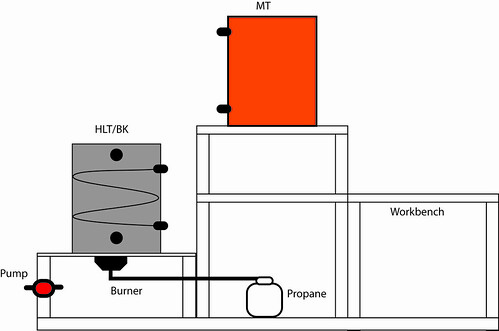

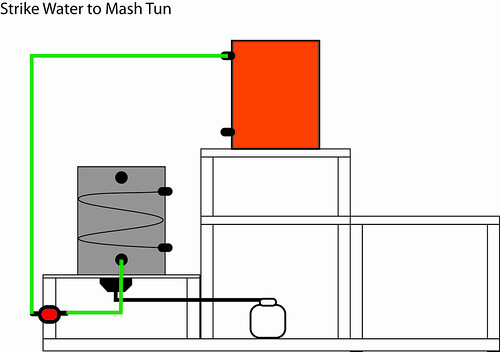

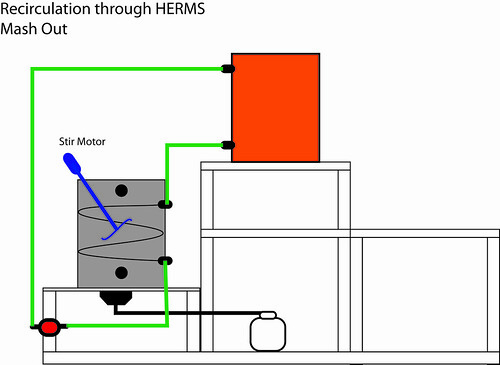

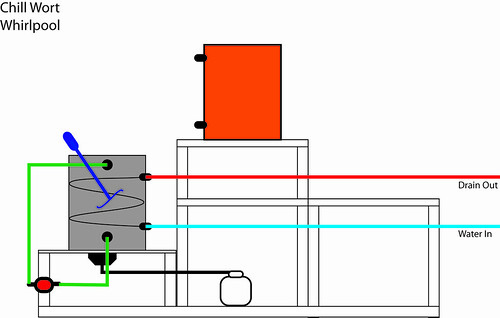

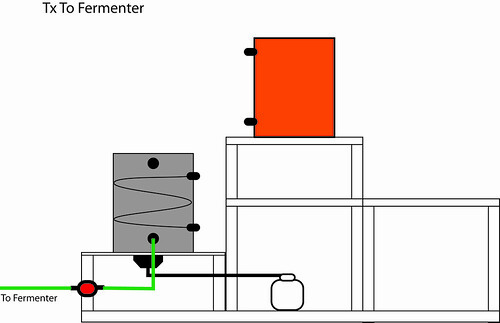

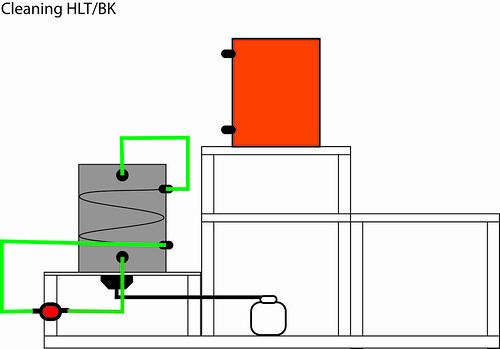

So I kind of stole what I liked from both these systems and designed my own. It is a two vessel, two tier system that utilizes a 10 gallon igloo MLT, a keggle HLT/BK, a single burner and a single pump. I will be building this initially on a wood frame with the idea that Ill eventually build a nice shiny metal stand. I'll incorporate a HERMS coil into the keggle that can be used to mash out and used as an immersion chiller after the boil.

Since I already had the igloo MLT, keggle and burner, this should be a relatively inexpensive build.

It won't be high on the bling factor right now, but the money I'm saving by not using two more keggles, two more burners and another pump I can use eventually to pretty this up.

I've gone over every permutation and combination of brewing system there is:

1 vs 2 vs 3 vessel, 1 vs 2 vs 3 tier, BIAB, HERMS, RIMS, driving myself crazy trying to design the AG system best suited to my needs. This is what I've finally come up with.

I don't have a lot of cash to throw at this, so first, the system has to be relatively inexpensive. But I want to be able to tweak, add and improve upon it as I develop my brewing skills and as I can afford it.

I want to keep the equipment list as short as possible. I love the simplicity of BIAB. So I started to think about a 1 vessel system. I like the idea of full volume mashing and can live with the loss of efficiency, but Im not crazy about lifting and transferring grain in a bag. So Ill need to incorporate a mash tun.

I love Lonnie's Brutus 2.0 concept as a method of keeping a mash tun in the equation:

http://www.alenuts.com/Alenuts/brutus20.html

I have an igloo cooler MLT so I wanted to use this in my system. The things I don't like about the Brutus 20 are the need to use 2 pumps and 2 burners.

I love jkarp's countertop Brutus 20:

https://www.homebrewtalk.com/f51/countertop-brutus-20-a-131411

It solves the two pump, two burner problem, but I don't want to use electricity and I want to be able to ramp this thing up to eventually do 10 gallon batches.

So I kind of stole what I liked from both these systems and designed my own. It is a two vessel, two tier system that utilizes a 10 gallon igloo MLT, a keggle HLT/BK, a single burner and a single pump. I will be building this initially on a wood frame with the idea that Ill eventually build a nice shiny metal stand. I'll incorporate a HERMS coil into the keggle that can be used to mash out and used as an immersion chiller after the boil.

Since I already had the igloo MLT, keggle and burner, this should be a relatively inexpensive build.

It won't be high on the bling factor right now, but the money I'm saving by not using two more keggles, two more burners and another pump I can use eventually to pretty this up.