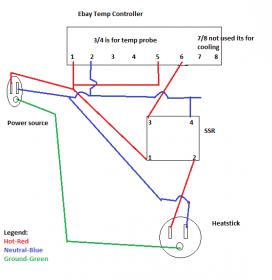

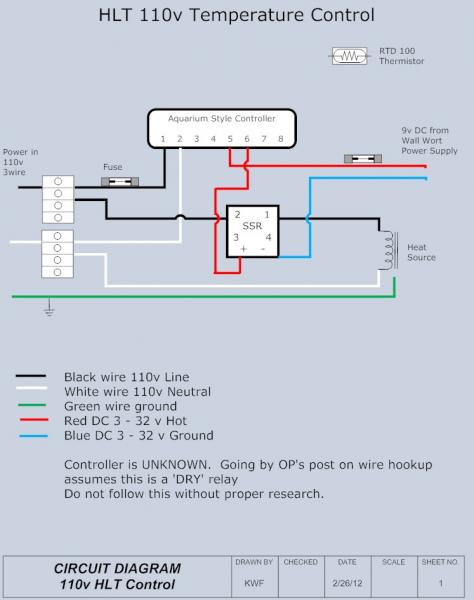

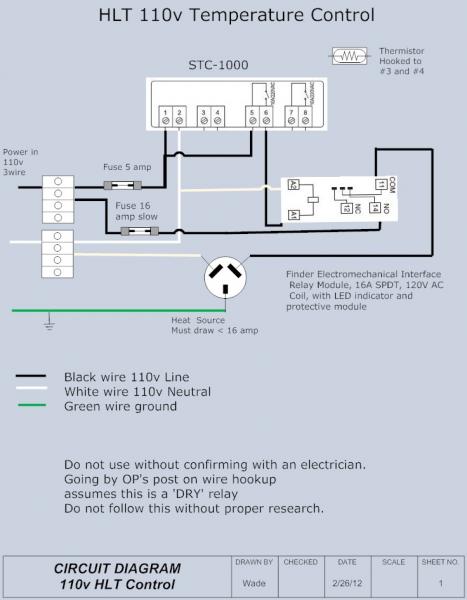

So I recently took a electric turkey fryer, gutted it and made it so theres no control and just plug in and it turns on, unplug its off. Now what im trying to do is make a temp controller for it, but have heard the ebay temp controllers (which im familiar with and have two for fridge control) arent good for the heating element because of amp draw.

Can someone help me in making a temp controller at a similar price range?

Also i need a way to manage the mixing/recirculation of the water to keep even temps, but dont want to spend 150 on a pump

Can someone help me in making a temp controller at a similar price range?

Also i need a way to manage the mixing/recirculation of the water to keep even temps, but dont want to spend 150 on a pump