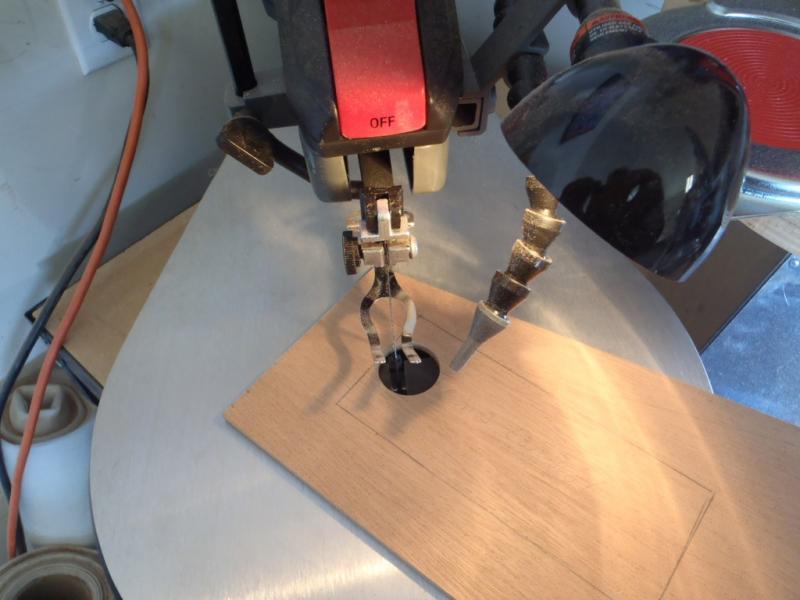

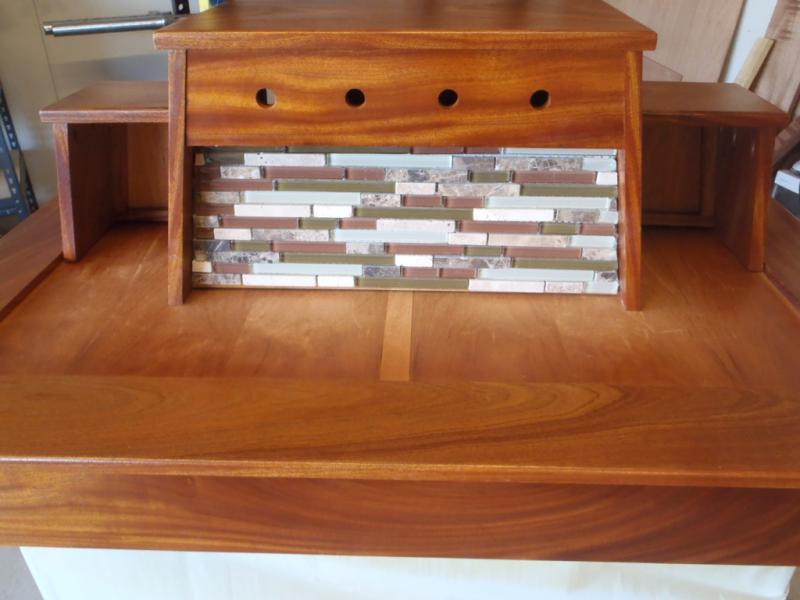

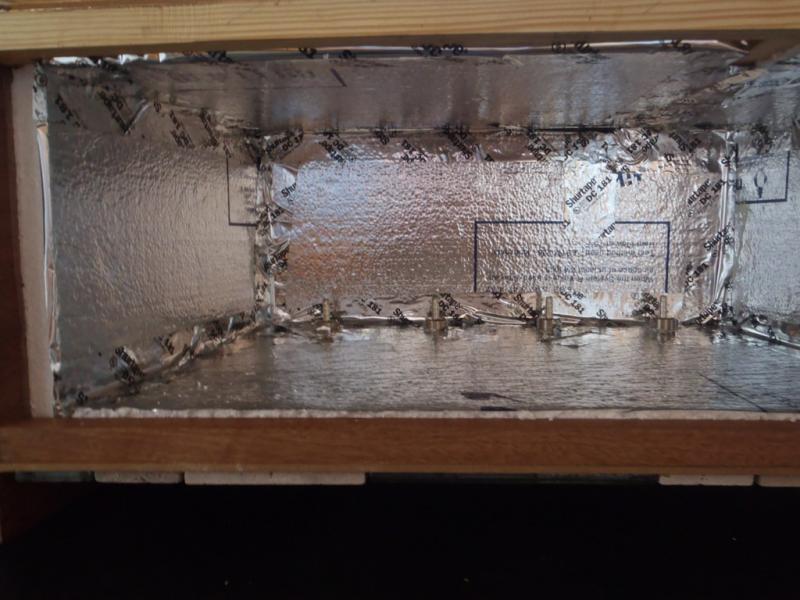

Now these are some first class wood working abilities!!! :rockin: Beautiful job on the keezer so far and excellent choice on the wood species. It's funny because when I was building my rustic keezer, people kept complimenting me on my "craftmanship" and "wood working skills". I kept telling everyone that I was a hack compared to some of the true wood workers on HBT. Installing knotty pine paneling around a 2x4 framed cabinet is a walk in the park compared to this build. I could easily hide my mistakes while trimming it out with cedar logs. Your precision is fantastic and the quality of your build is top notch! All of you future keezer builders take note of this build, because this is how a true professional builds a keezer! You 'da man!