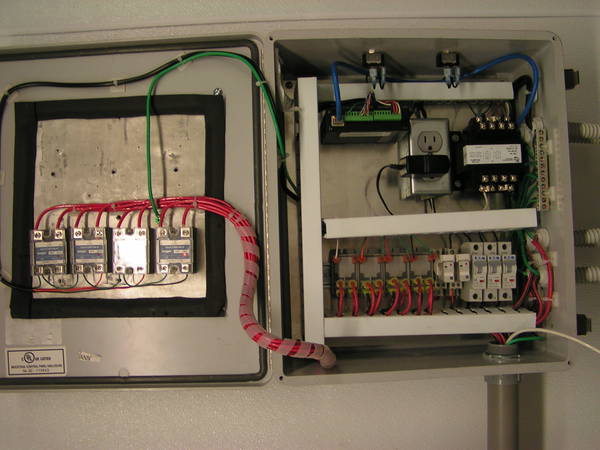

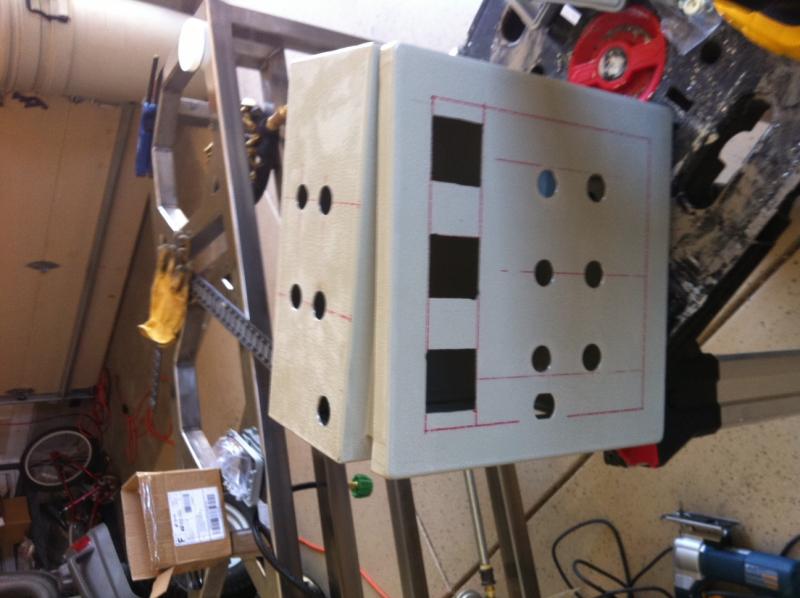

well, here is my brew rig. It is for a biab setup, but i made it big enough that i can expand to a 3 vessel system if i ever decide it will be better. The control panel is also capable of a 3 vessel system, should i choose to do that. I wanted all the plumbing to be compact and everything to be super easy to assemble and disassemble. I also wanted to to be quite tall so it can gravity drain into the fermentor. I bake my rims tube (without the element) and chiller between batches to turn any possible gunk into ash between runs, especially as i opted to not bother with a bypass of the chiller. It is constantly getting recirculated and has never clogged (there is a homemade hopstopper in the kettle that has been cogged, though), so i figured i could just keep recirculating through it. The extra pid at the bottom of the controller is a 4-20ma control pid, and it runs the orange valve which controls the outflow temperature (by limiting the flow rate) when cooling the wort. The black valve is a standard irrigation valve and controls the flow of chilling water. I am not showing the optional hopback. I base all of my brewing on weight, and have a scale under my kettle- this way i can always know exactly how much i have without having to wonder about the kettle being perfectly level and i don't have to worry about changing volumes based on temperature. I had to find one that didn't have an auto off, so i can keep an eye on the weight at all times without having to reset it. Also, i have not yet plumbed the carbon water filter into it yet, which comes off the main hose intake and will go to the kettle. I had it plumbed initially, but didn't realize how high pressure the water was- used silicone tubing which blew up and popped like a balloon.