scratchy1971

Well-Known Member

OK, this my first post to HBT. Been brewing for seven years now, mostly AG using coolers. We bought a larger house that has a full basement, so I now can dedicate some space for a brew room.

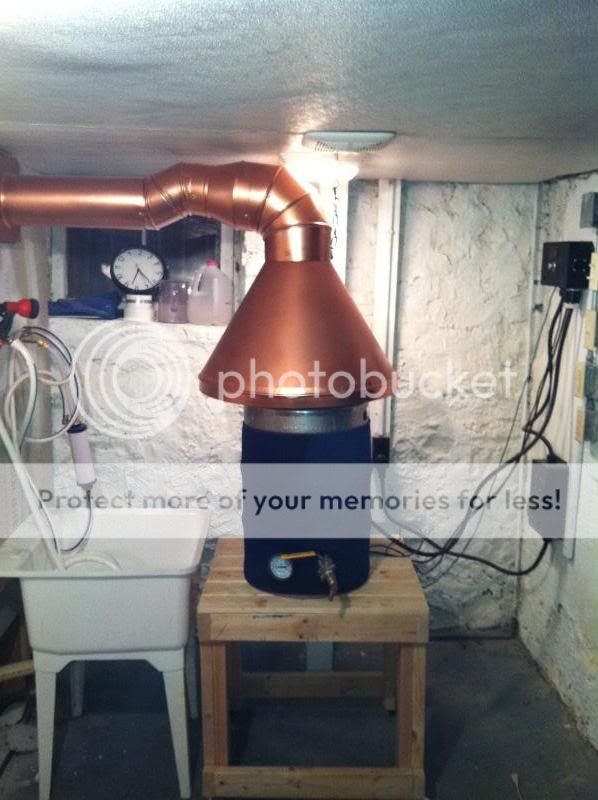

As you can see, the cornerstone of the operation will be the Brew-Magic system which I purchased this summer. After a few brews with it on the back patio, I moved it downstairs once winter kicked-in. I had spent countless hours researching what setup I wanted (build a BRUTUS, electric, just buy the Brew-Magic frame and do the rest myself, etc.). But, decided the best way for me to proceed once considering my DIY skill level and time, was to buy a system (I cannot weld or do advanced electrical). Choose to go with SABCO since I live in Ohio and could go pick it up to avoid freight. And, I really believe it is an excellent setup.

Choose this part of the basement since it has a floor drain and a tie-in to the main drain line. Also, has a window, is close to plumbing and gas lines. On the down side, the HVAC is also located here, which will complicate the ventilation a little.

I have been looking for used SS vent hoods, but most of what I find at restaurant auctions is either the wrong size, or has Ansul already built in and are pricey. My father-in-law has a farm in Kansas and his neighbor does some SS work, so sent him the specs. and waiting for him to get back to me on cost. Plan is to mount the hood on the joist on the back wall, use an inline fan mounted between the joists and cut a hole behind it to vent right to the back of the house. But, with the HVAC in the same area, I will most likely need to rig some type of make-up air. In addition, there is a lot of wiring running right where I would need to mount the duct and fan. So, still some things to work out.

As for other amenities, I want to find a used commercial SS double or triple bowl sink and maybe an SS table. I keep looking at closed restaurant auctions, and I will find the right one at some point.

I was also thinking of a used commercial fridge for lagering, and maybe build a closet to use for fermentation. But, have not worked all that out yet.

Anyway, I know this is a long post, but if anyone has any suggestions or idea's on what you would do, it would sure be appreciated.

As you can see, the cornerstone of the operation will be the Brew-Magic system which I purchased this summer. After a few brews with it on the back patio, I moved it downstairs once winter kicked-in. I had spent countless hours researching what setup I wanted (build a BRUTUS, electric, just buy the Brew-Magic frame and do the rest myself, etc.). But, decided the best way for me to proceed once considering my DIY skill level and time, was to buy a system (I cannot weld or do advanced electrical). Choose to go with SABCO since I live in Ohio and could go pick it up to avoid freight. And, I really believe it is an excellent setup.

Choose this part of the basement since it has a floor drain and a tie-in to the main drain line. Also, has a window, is close to plumbing and gas lines. On the down side, the HVAC is also located here, which will complicate the ventilation a little.

I have been looking for used SS vent hoods, but most of what I find at restaurant auctions is either the wrong size, or has Ansul already built in and are pricey. My father-in-law has a farm in Kansas and his neighbor does some SS work, so sent him the specs. and waiting for him to get back to me on cost. Plan is to mount the hood on the joist on the back wall, use an inline fan mounted between the joists and cut a hole behind it to vent right to the back of the house. But, with the HVAC in the same area, I will most likely need to rig some type of make-up air. In addition, there is a lot of wiring running right where I would need to mount the duct and fan. So, still some things to work out.

As for other amenities, I want to find a used commercial SS double or triple bowl sink and maybe an SS table. I keep looking at closed restaurant auctions, and I will find the right one at some point.

I was also thinking of a used commercial fridge for lagering, and maybe build a closet to use for fermentation. But, have not worked all that out yet.

Anyway, I know this is a long post, but if anyone has any suggestions or idea's on what you would do, it would sure be appreciated.