/*

* SD card attached to SPI bus as follows:

** MOSI - pin 11

** MISO - pin 12

** CLK - pin 13

** CS - pin 4

*/

#include <SD.h>

#include <OneWire.h>

#include <SPI.h>

#include <Ethernet.h>

/*********** SD Stuff ****************/

// On the Ethernet Shield, CS is pin 4. Note that even if it's not

// used as the CS pin, the hardware CS pin (10 on most Arduino boards,

// 53 on the Mega) must be left as an output or the SD library

// functions will not work.

const int chipSelect = 4;

/*********** ETHERNET STUFF ***********/

byte mac[] = { 0xDE, 0xAD, 0xBE, 0xEF, 0xFE, 0xED };

byte ip[] = { 192, 168, 1, 177 };

EthernetServer server(80);

#define BUFSIZ 100

/********** OneWire Stuff ************/

OneWire ds(9); // OneWire bus on pin 9

float celsius[10], fahrenheit[10];

int cnt=0, maxCnt;

/********** Radial Stuff ************/

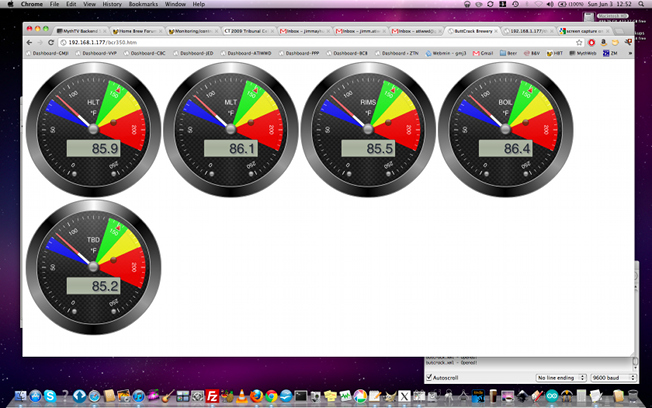

char *bcname[]={"HLT","MLT","RIMS","BOIL","TBD"};

char *bcrfn[]={"bcr100.htm","bcr150.htm","bcr200.htm","bcr250.htm","bcr300.htm","bcr350.htm"};

int bcrsize[]={100,150,200,250,300,350};

void setup()

{

// Open serial communications and wait for port to open:

Serial.begin(9600);

// Serial.print("Initializing SD card...");

// make sure that the default chip select pin is set to

// output, even if you don't use it:

pinMode(10, OUTPUT);

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

Serial.println(F("Card failed, or not present"));

// don't do anything more:

return;

}

// Serial.println(F("SD card initialized."));

// set up bcradial.htm

byte addr[8];

while ( ds.search(addr)) {

cnt++;

delay(500);

}

ds.reset_search();

// Serial.println("No more addresses.");

// Serial.println();

maxCnt = cnt;

cnt=0;

// Serial.print(F("maxCnt = "));

// Serial.println(maxCnt);

// create radial canvas files

//Serial.println(sizeof(bcrsize)/sizeof(int));

for(int cnta = 0; cnta < (sizeof(bcrsize)/sizeof(int)); cnta++)

{

SD.remove(bcrfn[cnta]);

writeBCRfile(bcrfn[cnta], bcrsize[cnta]);

}

// now start up the webserver

Ethernet.begin(mac, ip);

server.begin();

// Serial.print(F("Ethernet server is at "));

// Serial.println(Ethernet.localIP());

}

void getOneWire(void)

{

byte i;

byte present = 0;

byte type_s;

byte data[12];

byte addr[8];

if ( !ds.search(addr)) {

// Serial.println("No more addresses.");

// Serial.println();

maxCnt = cnt;

cnt=0;

ds.reset_search();

delay(500);

return;

}

/*

Serial.print("ROM ");

Serial.print(cnt);

Serial.print(" = ");

for( i = 0; i < 8; i++)

{

Serial.write(' ');

Serial.print(addr[i], HEX);

}

if (OneWire::crc8(addr, 7) != addr[7]) {

Serial.println("CRC is not valid!");

return;

}

Serial.println();

*/

// the first ROM byte indicates which chip

switch (addr[0]) {

case 0x10:

// Serial.println(" Chip = DS18S20"); // or old DS1820

type_s = 1;

break;

case 0x28:

// Serial.println(" Chip = DS18B20");

type_s = 0;

break;

case 0x22:

// Serial.println(" Chip = DS1822");

type_s = 0;

break;

default:

Serial.println(F("Not a DS18x20"));

return;

}

ds.reset();

ds.select(addr);

ds.write(0x44,1); // start conversion, with parasite power on at the end

delay(750); // maybe 750ms is enough, maybe not

// we might do a ds.depower() here, but the reset will take care of it.

present = ds.reset();

ds.select(addr);

ds.write(0xBE); // Read Scratchpad

// Serial.print(" Data = ");

// Serial.print(present,HEX);

// Serial.print(" ");

for ( i = 0; i < 9; i++) { // we need 9 bytes

data[i] = ds.read();

// Serial.print(data[i], HEX);

// Serial.print(" ");

}

// Serial.print(" CRC=");

// Serial.print(OneWire::crc8(data, 8), HEX);

// Serial.println();

// convert the data to actual temperature

unsigned int raw = (data[1] << 8) | data[0];

if (type_s) {

raw = raw << 3; // 9 bit resolution default

if (data[7] == 0x10) {

// count remain gives full 12 bit resolution

raw = (raw & 0xFFF0) + 12 - data[6];

}

} else {

byte cfg = (data[4] & 0x60);

if (cfg == 0x00) raw = raw << 3; // 9 bit resolution, 93.75 ms

else if (cfg == 0x20) raw = raw << 2; // 10 bit res, 187.5 ms

else if (cfg == 0x40) raw = raw << 1; // 11 bit res, 375 ms

// default is 12 bit resolution, 750 ms conversion time

}

celsius[cnt] = (float)raw / 16.0;

fahrenheit[cnt] = ((celsius[cnt] * 1.8) + 31.0);

// degC = (int)(celsius + 0.5);

// degF = (int)(((celsius * 1.8) + 32.0) + 0.5);

// Serial.print(" Temperature = ");

// Serial.print(celsius[cnt]);

// Serial.print(" Celsius, ");

// Serial.print(fahrenheit[cnt]);

// Serial.println(" Fahrenheit");

cnt++;

}

void writeBCRfile(char *filename, int size)

{

int cntz;

File bcrWriteFile = SD.open(filename, FILE_WRITE);

if (bcrWriteFile)

{

bcrWriteFile.println(F("<!DOCTYPE html>"));

bcrWriteFile.println(F("<html lang=\"en\">"));

bcrWriteFile.println(F("<head>"));

bcrWriteFile.println(F(" <meta charset=\"utf-8\" />"));

bcrWriteFile.println(F(" <title>ButtCrack Brewery</title>"));

bcrWriteFile.println(F(" <script type='text/javascript' src='http://www.buttcrackbrewery.com/js/Arduino/tween.js'></script>"));

bcrWriteFile.println(F(" <script type='text/javascript' src='http://www.buttcrackbrewery.com/js/Arduino/sslib1.js'></script>"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F(" <script type=\"application/javascript\">"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F("// Ajax request for xml data generated by Arduino"));

bcrWriteFile.println(F(" function ajaxUpdateValues()"));

bcrWriteFile.println(F(" {"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F(" var httpRequest;"));

bcrWriteFile.println(F(" var xmlDoc;"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F("// get the xml document via Ajax/http"));

bcrWriteFile.println(F(" httpRequest = new XMLHttpRequest();"));

bcrWriteFile.println(F(" httpRequest.onreadystatechange=function() {"));

bcrWriteFile.println(F(" if(httpRequest.readyState == 4) {"));

bcrWriteFile.println(F(" steamPress = Number(httpRequest.responseText);"));

bcrWriteFile.println(F(" }"));

bcrWriteFile.println(F(" }"));

bcrWriteFile.println(F(" httpRequest.open(\"GET\",\"http://192.168.1.177/butcrack.xml\",false);"));

bcrWriteFile.println(F(" httpRequest.send(null);"));

bcrWriteFile.println(F(" xmlDoc=httpRequest.responseXML;"));

bcrWriteFile.println(F("\n// update the global variables by parsing the xml document"));

for(cntz = 0; cntz < maxCnt; cntz++)

{

bcrWriteFile.print(F(" Temp"));

bcrWriteFile.print(cntz);

bcrWriteFile.print(F("=Number(xmlDoc.getElementsByTagName(\"Temp"));

bcrWriteFile.print(cntz);

bcrWriteFile.println(F("\")[0].childNodes[0].nodeValue);"));

}

bcrWriteFile.println(F(""));

bcrWriteFile.println(F(" }"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F(" function init()"));

bcrWriteFile.println(F(" {"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F("// Define section(s)"));

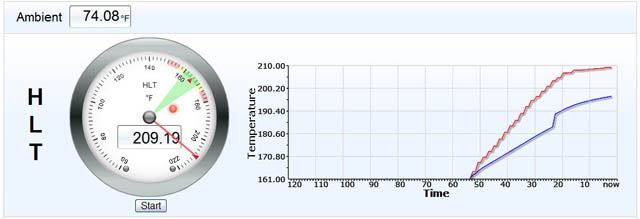

bcrWriteFile.print(F(" sections = Array(steelseries.Section(68, 80,\"rgba(0, 0, 254, 0.9)\"),\n\t steelseries.Section(140, 160,\"rgba(0, 254, 0, 0.9)\"),\n\t steelseries.Section(160, 180,\"rgba(254, 254, 0, 0.9)\"),\n\t steelseries.Section(180, 220, \"rgba(254, 0, 0, 0.9)\"));\n"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F("// Define area(s)"));

bcrWriteFile.print(F(" areas = Array(steelseries.Section(68, 80,\"rgba(0, 0, 254, 0.9)\"),\n\tsteelseries.Section(140, 160,\"rgba(0, 254, 0, 0.9)\"),\n\tsteelseries.Section(160, 180,\"rgba(254, 254, 0, 0.9)\"),\n\tsteelseries.Section(180, 220, \"rgba(254, 0, 0, 0.9)\"));\n"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F("// Initialize gauge"));

for(cntz = 0; cntz < maxCnt; cntz++)

{

bcrWriteFile.print(F(" radial"));

bcrWriteFile.print(cntz);

bcrWriteFile.print(F(" = new steelseries.Radial(\"Temp"));

bcrWriteFile.print(cntz);

bcrWriteFile.println(F("\", "));

bcrWriteFile.println(F(" {"));

// bcrWriteFile.println(F("// gaugeType: steelseries.GaugeType.TYPE3,"));

bcrWriteFile.print(F("\tsize: "));

bcrWriteFile.print(size);

bcrWriteFile.print(F(",\n\tminValue: 0,\n\tmaxValue: 220,\n\tthreshold: 152,\n\tsection: sections,\n\tarea: areas,\n\ttitleString: \""));

bcrWriteFile.print(bcname[cntz]);

bcrWriteFile.println(F("\",\n\tunitString: \"°F\",\n\tpointerType: steelseries.PointerType.TYPE2,\n\tframeDesign: steelseries.FrameDesign.BLACK_METAL,\n\tforegroundType: steelseries.ForegroundType.TYPE3,\n\tbackgroundColor: steelseries.BackgroundColor.CARBON,\n\tledVisible: true"));

bcrWriteFile.println(F(" });"));

bcrWriteFile.println(F(""));

}

bcrWriteFile.println(F(""));

bcrWriteFile.println(F("// Start the random update"));

bcrWriteFile.println(F(" setInterval(function(){ ajaxUpdateValues(); }, 5000); "));

for(cntz = 0; cntz < maxCnt; cntz++)

{

bcrWriteFile.print(F(" setInterval(function(){ setValue(radial"));

bcrWriteFile.print(cntz);

bcrWriteFile.print(F(", Temp"));

bcrWriteFile.print(cntz);

bcrWriteFile.println(F("); }, 10000);"));

}

// bcrWriteFile.println(F(""));

bcrWriteFile.println(F("\n }"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F(" function setValue(gauge, range)"));

bcrWriteFile.println(F(" {"));

bcrWriteFile.println(F(" gauge.setValueAnimated(range);"));

bcrWriteFile.println(F(" }"));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F(""));

bcrWriteFile.println(F("</script>"));

bcrWriteFile.println(F("<style>body {background: url(\"http://www.buttcrackbrewery.com/images/Arduino/bc.png\");}</style>"));

bcrWriteFile.println(F("</head>"));

bcrWriteFile.println(F("<body onload=\"init()\"> "));

for(cntz = 0; cntz < maxCnt; cntz++)

{

bcrWriteFile.print(F("\t<canvas id=\"Temp"));

bcrWriteFile.print(cntz);

bcrWriteFile.println(F("\">\n\tNo canvas in your browser...sorry...\n\t</canvas>"));

}

bcrWriteFile.println(F("</body>"));

bcrWriteFile.println(F("</html>"));

bcrWriteFile.close();

Serial.print(filename);

Serial.println(F(" written"));

} else {

// if the file didn't open, print an error:

Serial.println(F("error opening bcradial.htm"));

}

}

void writeXMLfile(void)

{

int cnty;

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File xmlWriteFile = SD.open("butcrack.xml", FILE_WRITE);

// if the file opened okay, write to it:

if (xmlWriteFile) {

// Serial.print("Writing to butcrack.xml...");

xmlWriteFile.print(F("<?xml version=\"1.0\" encoding=\"ISO-8859-1\"?>"));

xmlWriteFile.print(F("<!-- Created by Arduino Buttcrack sketch -->"));

xmlWriteFile.print(F("<buttcrack>"));

for (cnty = 0; cnty < maxCnt; cnty++)

{

xmlWriteFile.print(F("<Temp"));

xmlWriteFile.print(cnty);

xmlWriteFile.print(F(">"));

xmlWriteFile.print(fahrenheit[cnty],1);

xmlWriteFile.print(F("</Temp"));

xmlWriteFile.print(cnty);

xmlWriteFile.print(F(">"));

}

xmlWriteFile.print(F("</buttcrack>"));

// close the file:

xmlWriteFile.close();

// Serial.println("done.");

} else {

// if the file didn't open, print an error:

Serial.println(F("error opening butcrack.xml"));

}

}

/*

void readXMLfile(void)

{

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File xmlReadFile = SD.open("butcrack.xml");

// if the file is available, write to it:

if (xmlReadFile)

{

while (xmlReadFile.available())

{

Serial.write(xmlReadFile.read());

}

xmlReadFile.close();

} else {

// if the file isn't open, pop up an error:

Serial.println("error opening butcrack.xml");

}

}

*/

void writeTemperatureFile(void)

{

int cntx;

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File tempWriteFile = SD.open("thermo.htm", FILE_WRITE);

// if the file opened okay, write to it:

if (tempWriteFile)

{

// Serial.print(F("Writing to thermo.htm..."));

tempWriteFile.println(F("HTTP/1.1 200 OK"));

tempWriteFile.println(F("Content-Type: text/html"));

tempWriteFile.println(F("Connnection: close"));

tempWriteFile.println();

tempWriteFile.println(F("<!DOCTYPE HTML>"));

tempWriteFile.println(F("<html>"));

// add a meta refresh tag, so the browser pulls again every 60 seconds:

tempWriteFile.println(F("<meta http-equiv=\"refresh\" content=\"60\">"));

// output the value of each analog input pin

tempWriteFile.println(F("<table><tr>"));

for(cntx=0 ; cntx < maxCnt ; cntx++)

{

tempWriteFile.print(F("<td Align=\"center\" valign=\"top\">"));

tempWriteFile.print(F("    Ambient Temperature "));

tempWriteFile.print(cntx);

tempWriteFile.print(F(":    <br /><br /><font size=\"10\">"));

tempWriteFile.print(fahrenheit[cntx], 1);

tempWriteFile.println(F("°</font>F"));

tempWriteFile.print(F("<br /><font size=\"8\">"));

tempWriteFile.print(celsius[cntx], 1);

tempWriteFile.print(F("°</font>C"));

tempWriteFile.println(F("</td>"));

}

tempWriteFile.println(F("</tr></table>"));

tempWriteFile.println(F("</html>"));

// close the file:

tempWriteFile.close();

// Serial.println("done.");

} else {

// if the file didn't open, print an error:

Serial.println(F("error opening thermo.htm"));

}

}

/*

void readTemperaturefile(void)

{

// open the file. note that only one file can be open at a time,

// so you have to close this one before opening another.

File tempReadFile = SD.open("thermo.htm");

// if the file is available, write to it:

if (tempReadFile)

{

while (tempReadFile.available())

{

Serial.write(tempReadFile.read());

}

tempReadFile.close();

} else {

// if the file isn't open, pop up an error:

Serial.println("error opening thermo.htm");

}

}

*/

void checkForInternetRequest(void)

{

char clientline[BUFSIZ];

char *filename;

int index = 0;

int image = 0;

EthernetClient client = server.available();

if (client) {

// an http request ends with a blank line

boolean current_line_is_blank = true;

// reset the input buffer

index = 0;

while (client.connected()) {

if (client.available()) {

char c = client.read();

// If it isn't a new line, add the character to the buffer

if (c != '\n' && c != '\r') {

clientline[index] = c;

index++;

// are we too big for the buffer? start tossing out data

if (index >= BUFSIZ)

index = BUFSIZ -1;

// continue to read more data!

continue;

}

// got a \n or \r new line, which means the string is done

clientline[index] = 0;

filename = 0;

// Print it out for debugging

// Serial.println(clientline);

/*

// Look for substring such as a request to get the root file

if (strstr(clientline, "GET / ") != 0)

{

filename = rootFileName;

}

*/

if (strstr(clientline, "GET /") != 0) {

// this time no space after the /, so a sub-file

if (!filename) filename = clientline + 5; // look after the "GET /" (5 chars)

// a little trick, look for the " HTTP/1.1" string and

// turn the first character of the substring into a 0 to clear it out.

(strstr(clientline, " HTTP"))[0] = 0;

// print the file we want

if (

(strstr(filename, ".htm") != 0) |

(strstr(filename, ".xml") != 0) |

(strstr(filename, ".js") != 0)

)

{

Serial.print(filename);

File webReadFile = SD.open(filename);

if (webReadFile)

{

Serial.println(F(" - Opened!"));

while (webReadFile.available())

{

client.write(webReadFile.read());

}

webReadFile.close();

} else {

// if the file isn't open, pop up an error:

Serial.print(" - error");

// Serial.println(filename);

client.println(F("HTTP/1.1 404 Not Found"));

client.println(F("Content-Type: text/html"));

client.println();

client.println(F("<h2>File Not Found!</h2>"));

break;

}

webReadFile.close();

} else {

// everything else is a 404

client.println(F("HTTP/1.1 404 Not Found"));

client.println(F("Content-Type: text/html"));

client.println();

client.println(F("<h2>File Not Found</h2>"));

}

break;

}

}

}

// give the web browser time to receive the data

delay(1);

client.stop();

}

}

void loop()

{

// readXMLfile();

// readTemperaturefile();

SD.remove("butcrack.xml");

SD.remove("thermo.htm");

getOneWire();

writeXMLfile();

writeTemperatureFile();

checkForInternetRequest();

// delay(2000);

}

) since I've done any hardware prototyping or coding. It's fun, but I really don't miss the daily grind.

) since I've done any hardware prototyping or coding. It's fun, but I really don't miss the daily grind.