Douglefish

Well-Known Member

- Joined

- Dec 22, 2008

- Messages

- 263

- Reaction score

- 2

When using a 240 V Heating Element, should you use 1 or 2 SSRs?

If you only use 1, will the element still be hot?

If you only use 1, will the element still be hot?

When using a 240 V Heating Element, should you use 1 or 2 SSRs?

If you only use 1, will the element still be hot?

So what is the advantage of using 2 SSRs?

This is why I have a DPST switch for each of my elements. I don't use my PID to turn my elements on and off. I simply use the PID to control temp. Hence, I only have one SSR per element. If I used the PID to turn my elements on and off, I would have two SSRs per element.

It's already been said but I would think you want a DPDT mechanical kill switch for the "real" off off.

I haven't used them. Do they not make a 2-pole SSR?

I agree. I like some indicator of true off. Call me old school but I used a definate purpose contactor for my HLT. It "clunks" on and "clunks" off and hums a bit when its on.

Do they not make a 2-pole SSR?

It's already been said but I would think you want a DPDT mechanical kill switch for the "real" off off.

when wiring up 2 ssr's for a 240 element do you run 2 wires from the controller (brewtroller in my case) terminals to the ssr or run them in series? (the 2 wire method seems logical, but i've been wrong before...)

when wiring up 2 ssr's for a 240 element do you run 2 wires from the controller (brewtroller in my case) terminals to the ssr or run them in series? (the 2 wire method seems logical, but i've been wrong before...)

Run them in parallel. a set of wires from the BCS to the first SSR and then another set of wires from the first to the second SSR.

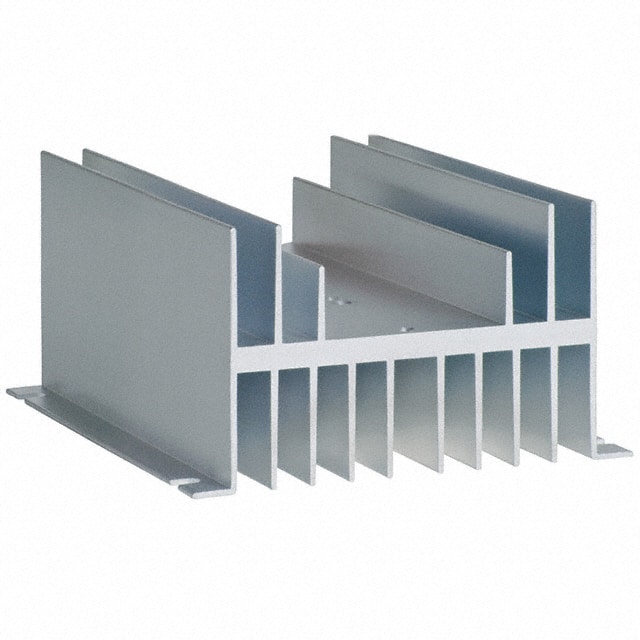

Ok, so I was wondering. If I use two 2 SSR's on the 5500W element, do the SSR's need to be 25A each or 40A each. Since I am only putting one leg per SSR is the 40A necessary on each or would the 25A be sufficient. Of course I would have heatsinks on each SSR.

Enter your email address to join: