I'm planning on testing a couple of different magnet orientations using a SS washer with small, round rare earth magnets from EBay mounted on it. Not sure which way would work the best, what do you think will work best?

First one is an Inline orientation, with two magnets of each polarity on each side of the washer. Having two magnets will hopefully increase the amount of pull they have on the stirbar, preventing it being thrown. Having the magnets inline should hopefully allow it to self-center the bar.

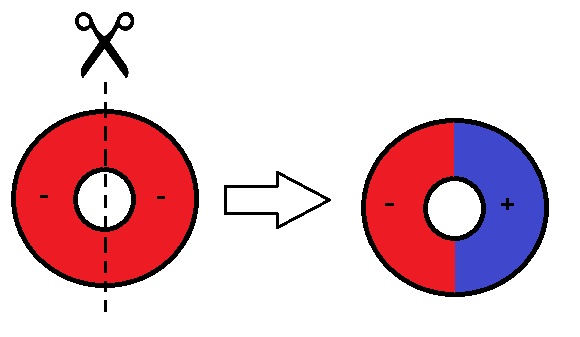

The other is radially oriented magnets. I wonder if having each end arranged this way will help "trap" the stirbar between them. Also I wonder if the stirbar will self center, or simply grab onto whatever field is closest...

First one is an Inline orientation, with two magnets of each polarity on each side of the washer. Having two magnets will hopefully increase the amount of pull they have on the stirbar, preventing it being thrown. Having the magnets inline should hopefully allow it to self-center the bar.

The other is radially oriented magnets. I wonder if having each end arranged this way will help "trap" the stirbar between them. Also I wonder if the stirbar will self center, or simply grab onto whatever field is closest...