BrewThruYou

Well-Known Member

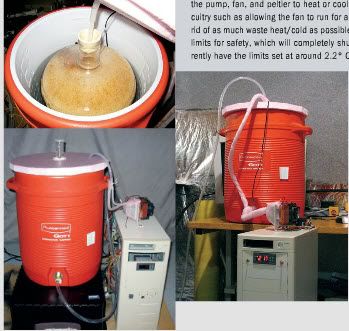

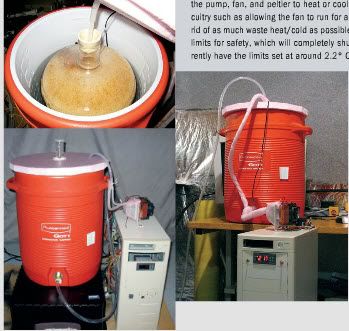

Not sure if everyone saw the gadget issue, but I'm looking at recreating or reimagining the 10G igloo water cooler fermentation chamber. The guy who built it says it's basically a copper heatsink/fan from an old computer, a peltier device and a water block/pump used for computer processing cooling. There's a temperature control module that will regulate the temp.

In researching, I did come across this thread: https://www.homebrewtalk.com/f51/water-fermentation-chiller-81501/

However, the difference is that the zymurgy guy's above can heat and cool with the peltier device and it doesn't require a separate water vessel for ice water. The separate vessel would also require refilling with ice water when cooling.

I had a few questions:

1. Any problems with using a bucket instead of a glass carboy? I already have 4 buckets and 6.5G carboys are $42 plus tax.

2. Any idea how to build it?

In researching, I did come across this thread: https://www.homebrewtalk.com/f51/water-fermentation-chiller-81501/

However, the difference is that the zymurgy guy's above can heat and cool with the peltier device and it doesn't require a separate water vessel for ice water. The separate vessel would also require refilling with ice water when cooling.

I had a few questions:

1. Any problems with using a bucket instead of a glass carboy? I already have 4 buckets and 6.5G carboys are $42 plus tax.

2. Any idea how to build it?