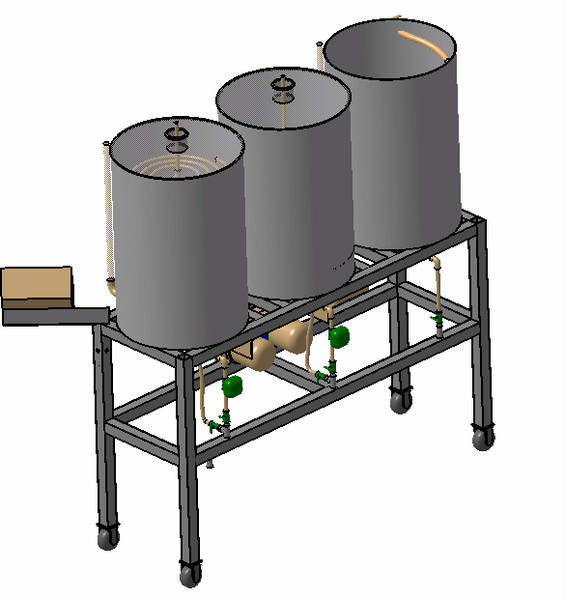

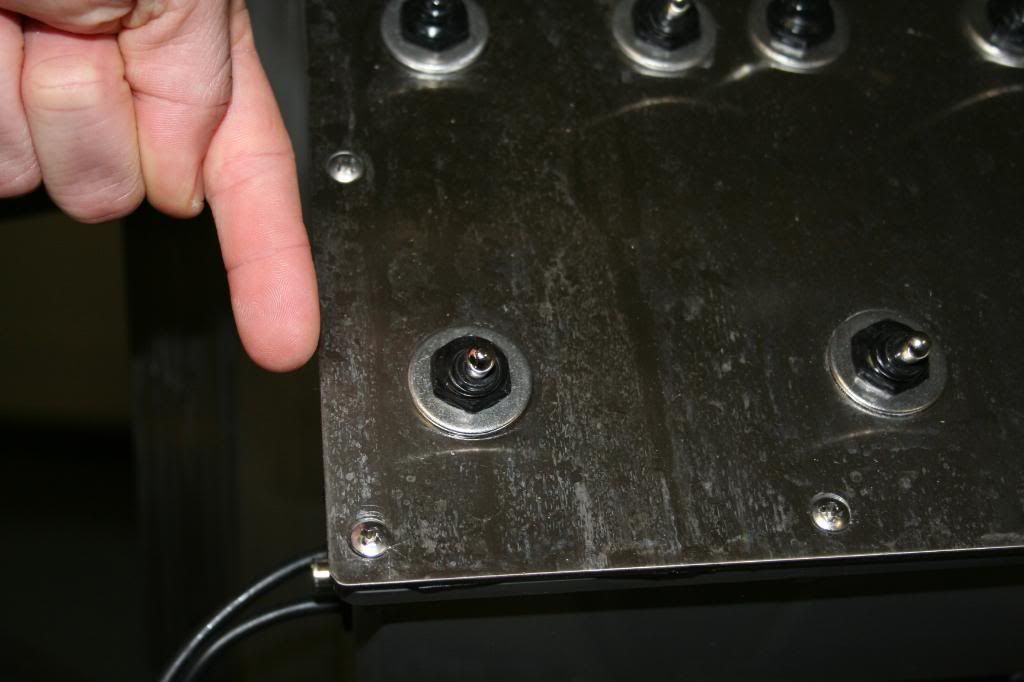

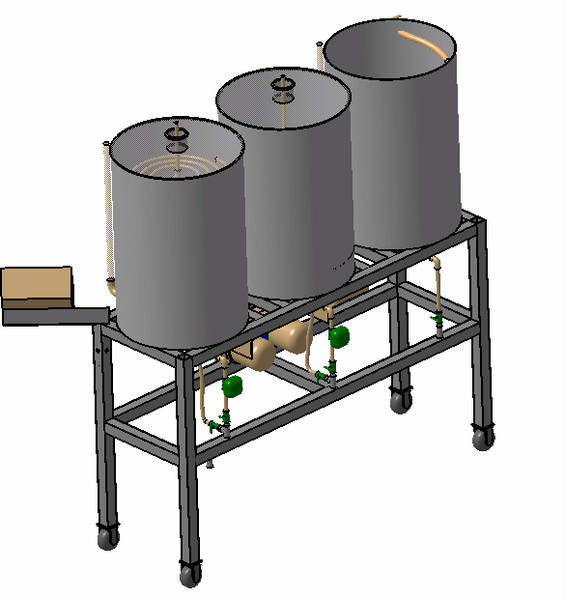

Well I am getting closer to having all the parts I need. (burners came in today) That puts me at about 50%. I just thought I would put up some pictures of the build and ask if there is any suggestions on things to add. I modified it slightly to how I wanted to brew with it but I may change my mind by the time it gets done. I also have a 2D drawing that shows everything for assembly and wiring. Most of the things I changed were either Asco type, or the things that go into my kegs (ie adding whirlpool, changing the returns, etc) Also I added a pivoting arm that has the control panel mounted on it. The pictures may not show it very well but it locks in with a bolt and rotates 90 degrees.

For the most part though the stand part is still Lonnie Macs design

For the most part though the stand part is still Lonnie Macs design