-TH-

Well-Known Member

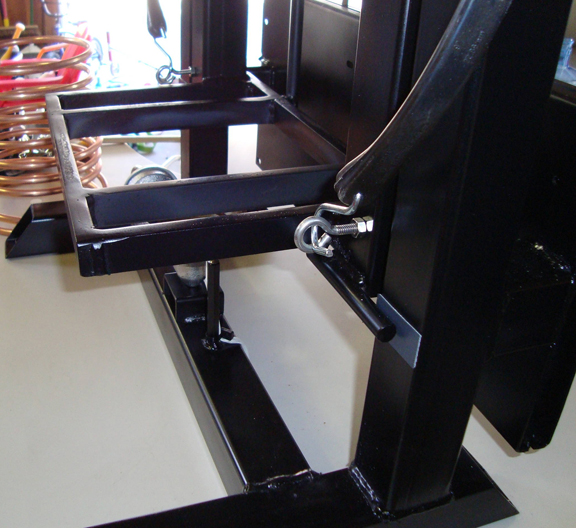

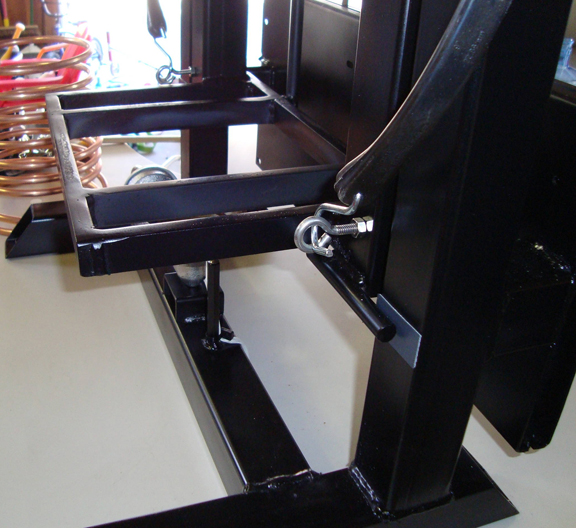

My ever-changing rig has been modified again. This time I built a tippy dump for it. I really like it for batch sparging, and I also use it to dump the grains when doughing in which makes it easier to stir at the same time. Also having a 2nd burner is nice too. Of course it has a piezo igniter just like the main burner. Enjoy the pics...