doublehaul

Well-Known Member

Thought I would post up my notes from my first AG attempt because I have a feeling I have made a few critical mistakes that made me miss my OG. I'd appreciate any feedback!

Recipe Arrogant Bastard Clone

15 lbs grain

Mash temp: 148, OG 1.071, FG 1.019, ABV: 7.13%, Batch size 5.25 gallons, Boil Size: 7 gallons, efficiency: 70%

Batch Sparge

Equipment – 10 gallon round cooler, ss braid, 10 gallon boil pot

Thurs.

Got Yeast starter going

Sat 8am BREW DAY

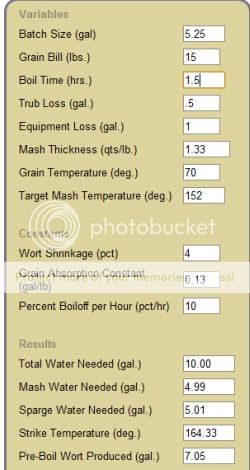

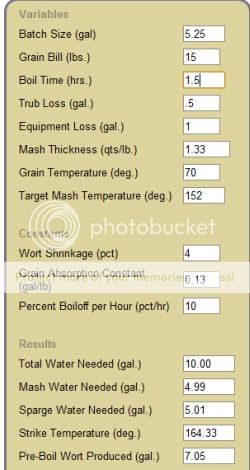

First of all I calculated my water amounts/temps from brew365.com with the default settings.

EDIT - this screenshot should say mash temp 148, strike temp 159.73.

Put 2 (1 gallon?) pots hot tap water in cooler, put on lid to pre-heat. Shook a bit.

Brought 5 gallons to 162degF

Drained pre-heat water from mash tun – note water left after drain under ½ gallon.

9am Doughed in – adding grain/water a pot at a time. Only hit about 143 so stirred in (½ gallon) pot of boiling water brought it up to 149. Put lid on. I don't know that I could handle a much bigger batch, which surprised me.

Ran to hardware store to get another hose for my wort chiller – wife watched the stove.

9:30 am Stirred – temp still 149.

Overheated sparge water so turned off flame, cooled to 175 and dumped into a spare (sanitized) cooler. Closed lid an put a towel on to insulate.

Mashed for 70 minutes – recipe did not give a time.

10:10am Recirculated and finished lautering at – process went smooth. Collected a little over 3 gallons. Should I have had more?

Strike water temp a little low (barely 165). Tried stirring in a bit of boiling water and didn't help. Temp was maybe 162? Added 5gallons of strike water scooping the first half with a pitcher and then holding the cooler over my mash tun, pouring through the drain spout – pain in the ass. Let sit for 15 minutes. Collected so I had a little over 7 gallons which is what I needed, but there was definitely more – I poured at least 1 gallon down the sink – should I have collected this and boiled it off? Were my water numbers incorrect? Is this what made me miss my OG?

Pre-Boil Gravity 1.057. From the palmer book – (57 * 7.05)/15 = 26.79. “The result should be somewhere around 28. 27 is OK, 29 is better, and above 30 is great. If it is 25 or below, you are not getting good conversion in the mash..” I was pretty happy with 26.79 for my first attempt. Is this my efficiency?

11am

Started boil

90 minute boil

Finished with 6 gallons in the pot, hops and all. Had a litte freak out, but ended up with 5.25 gallons in the ferementer, just like I was supposed to – so I guess the calculator was good in that respect. Cooled with wort chiller (first time using one – awesome!).

I'm calling my FG 1.6 - the temp is 70 so you are supposed to add a point - what do you think?

Recipe Arrogant Bastard Clone

15 lbs grain

Mash temp: 148, OG 1.071, FG 1.019, ABV: 7.13%, Batch size 5.25 gallons, Boil Size: 7 gallons, efficiency: 70%

Batch Sparge

Equipment – 10 gallon round cooler, ss braid, 10 gallon boil pot

Thurs.

Got Yeast starter going

Sat 8am BREW DAY

First of all I calculated my water amounts/temps from brew365.com with the default settings.

EDIT - this screenshot should say mash temp 148, strike temp 159.73.

Put 2 (1 gallon?) pots hot tap water in cooler, put on lid to pre-heat. Shook a bit.

Brought 5 gallons to 162degF

Drained pre-heat water from mash tun – note water left after drain under ½ gallon.

9am Doughed in – adding grain/water a pot at a time. Only hit about 143 so stirred in (½ gallon) pot of boiling water brought it up to 149. Put lid on. I don't know that I could handle a much bigger batch, which surprised me.

Ran to hardware store to get another hose for my wort chiller – wife watched the stove.

9:30 am Stirred – temp still 149.

Overheated sparge water so turned off flame, cooled to 175 and dumped into a spare (sanitized) cooler. Closed lid an put a towel on to insulate.

Mashed for 70 minutes – recipe did not give a time.

10:10am Recirculated and finished lautering at – process went smooth. Collected a little over 3 gallons. Should I have had more?

Strike water temp a little low (barely 165). Tried stirring in a bit of boiling water and didn't help. Temp was maybe 162? Added 5gallons of strike water scooping the first half with a pitcher and then holding the cooler over my mash tun, pouring through the drain spout – pain in the ass. Let sit for 15 minutes. Collected so I had a little over 7 gallons which is what I needed, but there was definitely more – I poured at least 1 gallon down the sink – should I have collected this and boiled it off? Were my water numbers incorrect? Is this what made me miss my OG?

Pre-Boil Gravity 1.057. From the palmer book – (57 * 7.05)/15 = 26.79. “The result should be somewhere around 28. 27 is OK, 29 is better, and above 30 is great. If it is 25 or below, you are not getting good conversion in the mash..” I was pretty happy with 26.79 for my first attempt. Is this my efficiency?

11am

Started boil

90 minute boil

Finished with 6 gallons in the pot, hops and all. Had a litte freak out, but ended up with 5.25 gallons in the ferementer, just like I was supposed to – so I guess the calculator was good in that respect. Cooled with wort chiller (first time using one – awesome!).

I'm calling my FG 1.6 - the temp is 70 so you are supposed to add a point - what do you think?