WPStrassburg

Well-Known Member

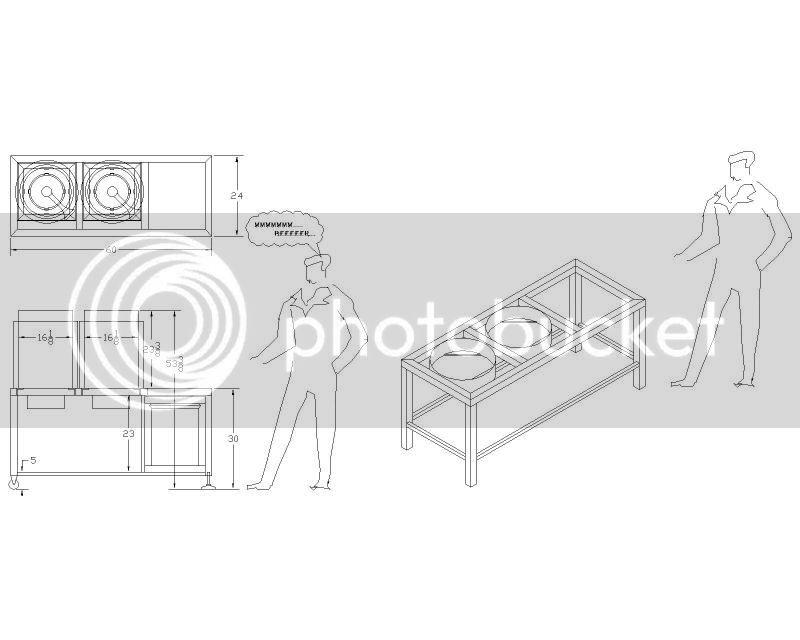

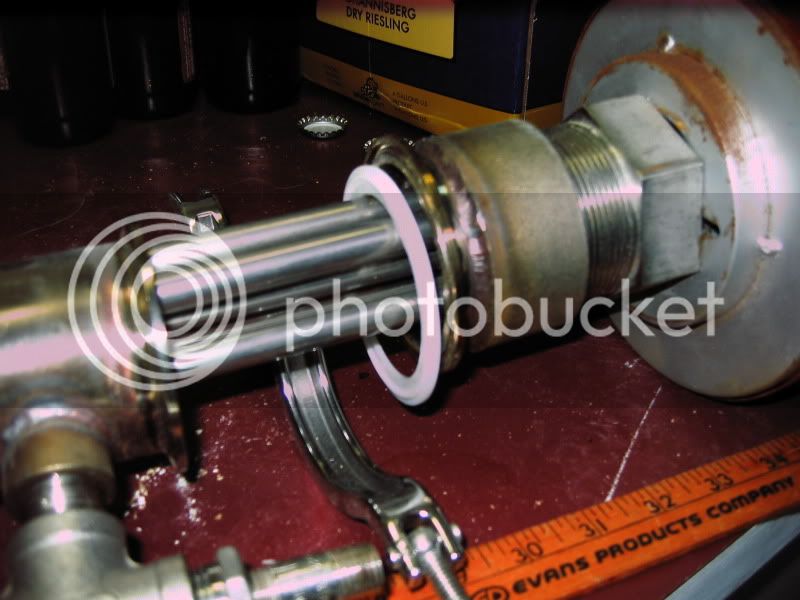

I'm slowly getting all my parts together and finally dry fit up my rims tube. The element is a 6kw ss chromalox process heater. Watt density was around 40w/in2 iirc and was less the ulwd ripp elements. The tube is 2.5" and 28" long with triclovers on both ends. I had a 2" fpt welded to a tc ferrule and that's where the element threads in. The other end of the tube is just capped. The cap is made from a short ferrule with a piece of 20 ga ss welded to it. I had spare ferrules and it was cheaper to weld up a cap rather than buying one. The plan is to pump into the bottom of the tube, out the top, and recirc back through the pump whatever doesn't go to the mash tun. The cross has tow valves, the top goes to the tun, the left one is the recirc back to the pump. By doing this I'll be able to do a full speed flow through the tube and keep temps constant while getting just what I need going into the tun. The right leg of the cross is where the temp sensor will be going to the auber 2352 pid that runs the chromalox scr.

I used 1/2" polypropeleyne cam locks from proflow and they've been working great on my pump and chiller the past few brews and will have them on the whole rig once it's done.

Overall shot of the beast

Closeup of the cross and diverter valves and location on the right of the temp sensor.

npt to tc connections

Endcap

Broken down

Enjoy and let me know what you think.

I used 1/2" polypropeleyne cam locks from proflow and they've been working great on my pump and chiller the past few brews and will have them on the whole rig once it's done.

Overall shot of the beast

Closeup of the cross and diverter valves and location on the right of the temp sensor.

npt to tc connections

Endcap

Broken down

Enjoy and let me know what you think.