canyonbrewer

Well-Known Member

Hello All -

PJ probably doesn't remember, but he talked me into a HERMS (rather than RIMS)

Just wanted to start a thread to post my progress...

starting with some random pics....more to come

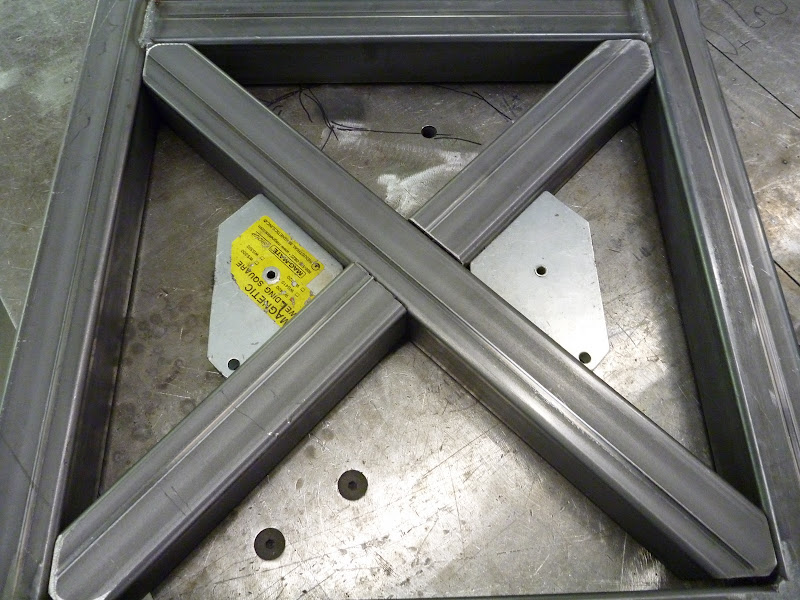

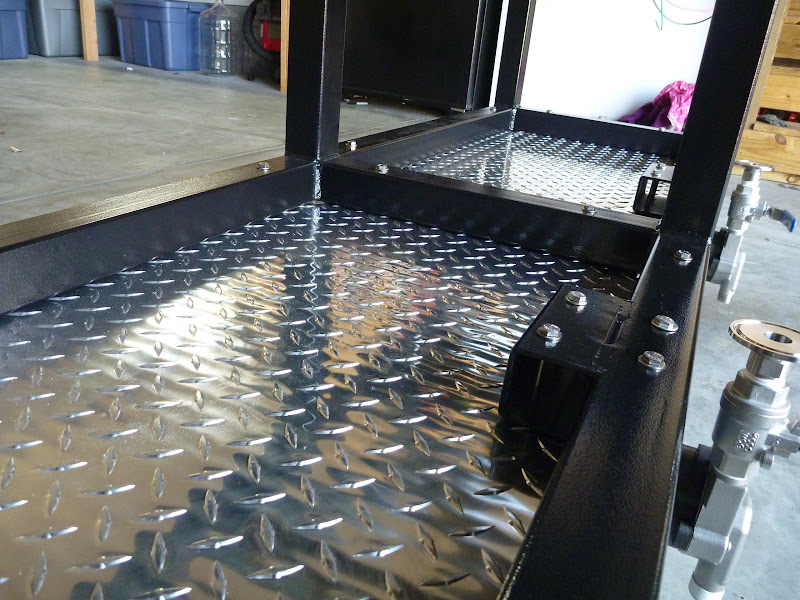

metal for stand

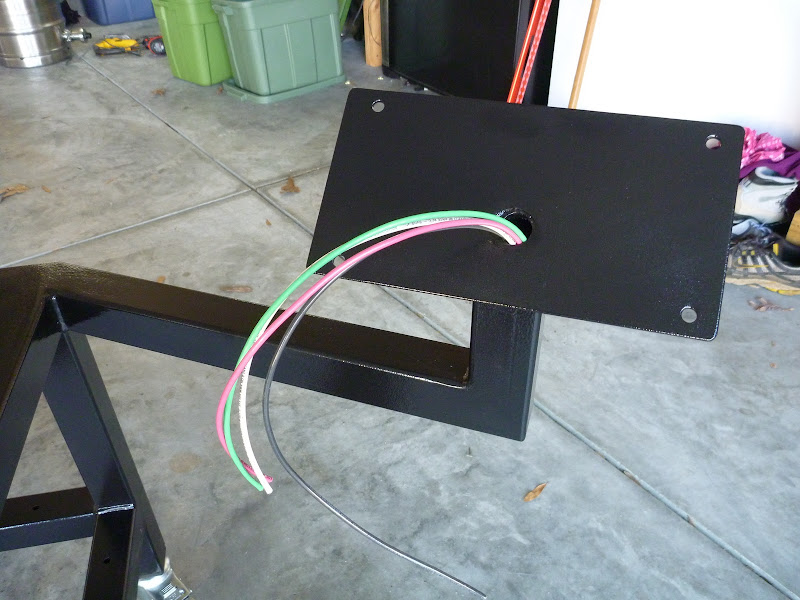

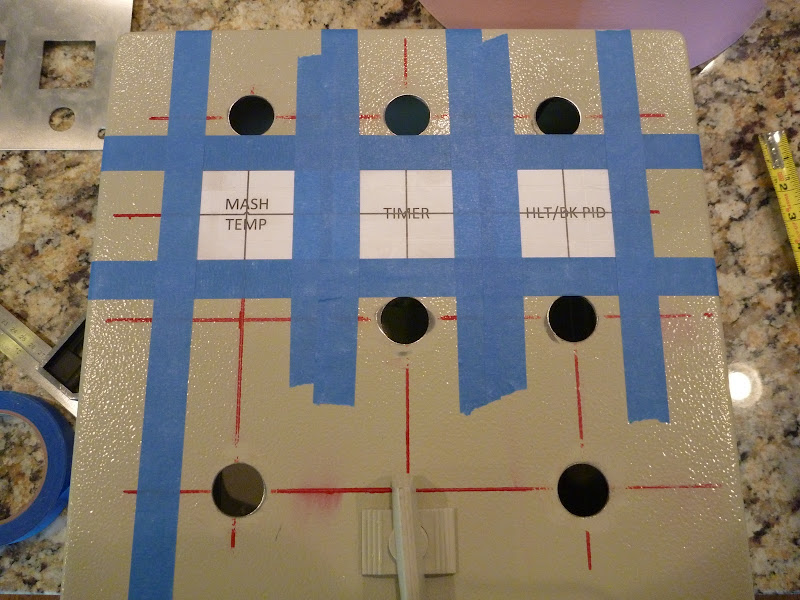

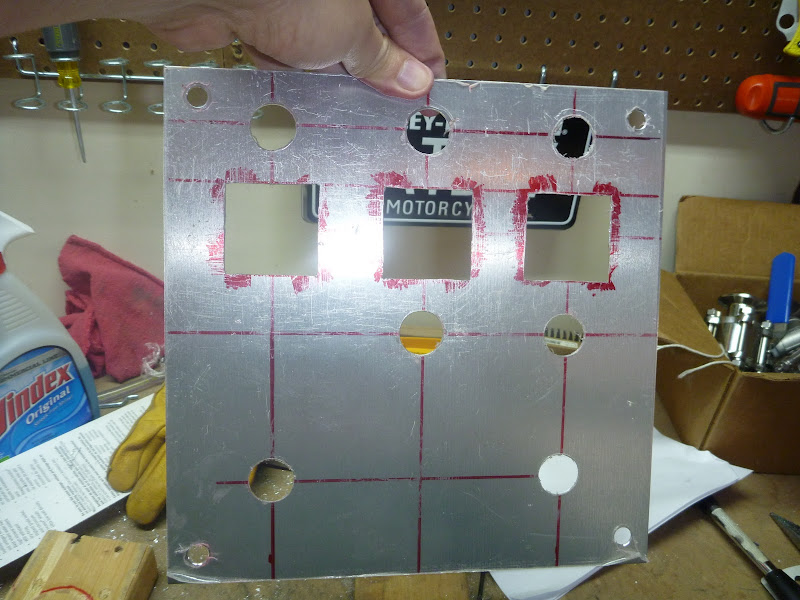

cut inner control panel - this is aluminum that will go inside my control box using custom standoffs

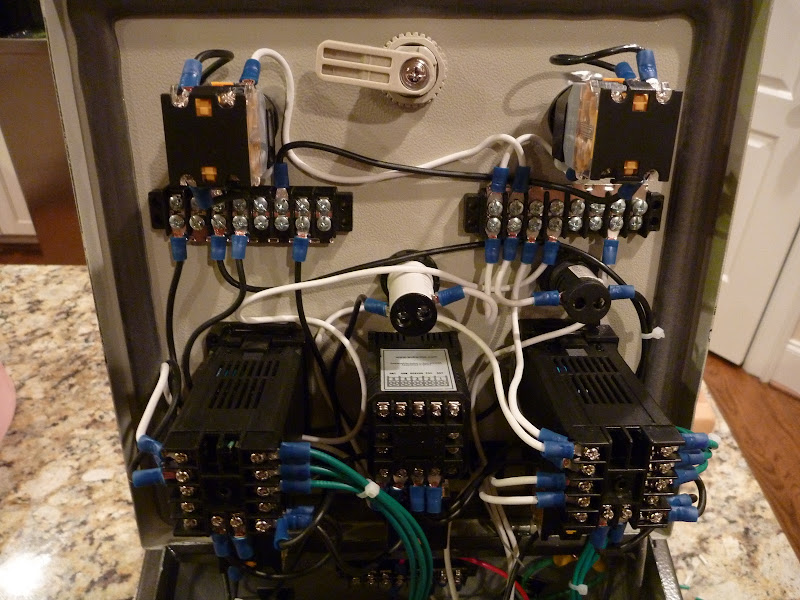

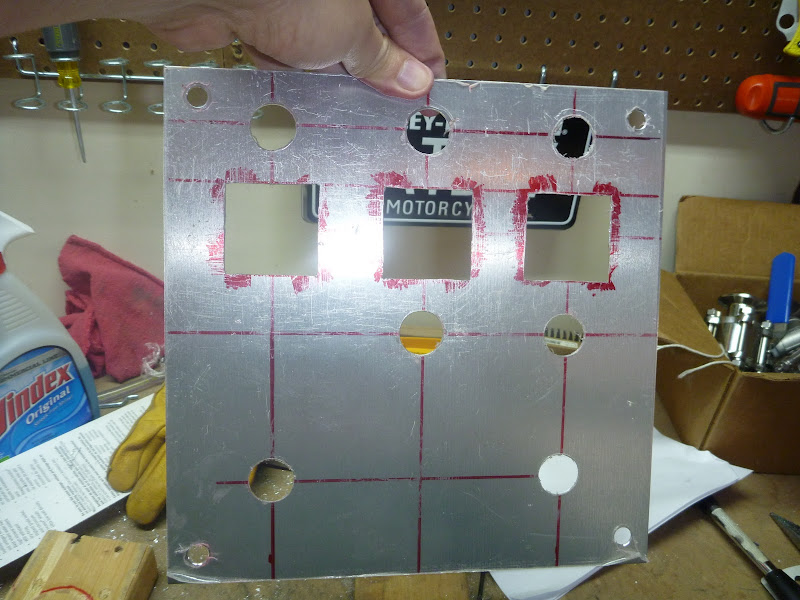

control panel with components mock installed

new TC port on my brew kettle - for electric element

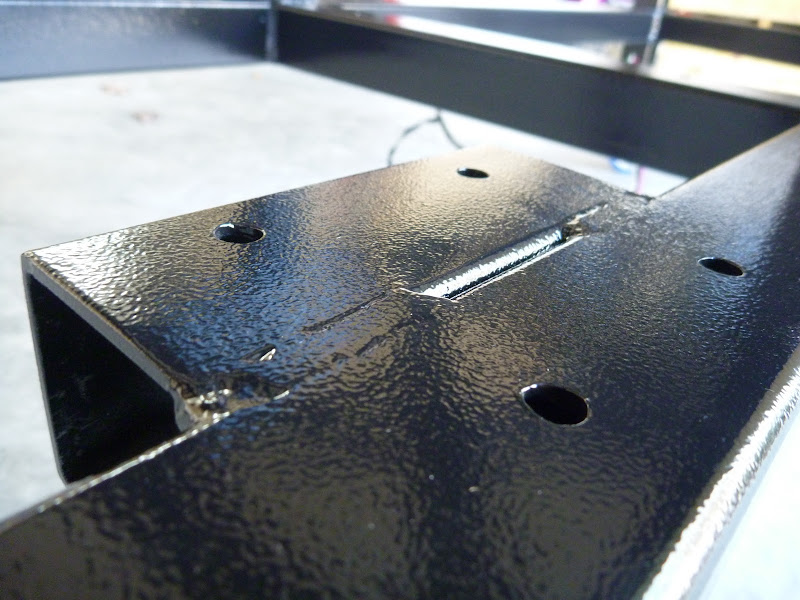

great weld...crappy picture

PJ probably doesn't remember, but he talked me into a HERMS (rather than RIMS)

Just wanted to start a thread to post my progress...

starting with some random pics....more to come

metal for stand

cut inner control panel - this is aluminum that will go inside my control box using custom standoffs

control panel with components mock installed

new TC port on my brew kettle - for electric element

great weld...crappy picture