JuanMoore

Getting the banned back together

Ah, I didn't know that. How long is the delay?

See my edit above. IIRC factory setting is 3 min.

Ah, I didn't know that. How long is the delay?

I don't have the STC (using the love TSS2) but with any controller -

use a couple of lamps - and have some warm water and ice water - then move the probe from one to the other and see if the lamps come on appropriately - that way you're not hard-cycling your compressor during the test/troubleshoot phase.

Ah, I didn't know that. How long is the delay?

As Bugs Bunny would say, "What a Maroon!"

I, too, was a ******* today. Finally figured out the bloken engrish of the instructions, and waited the required 3 mins, heard a click, saw a light, got power to the plug! All is well, hope that is your only problem as well.

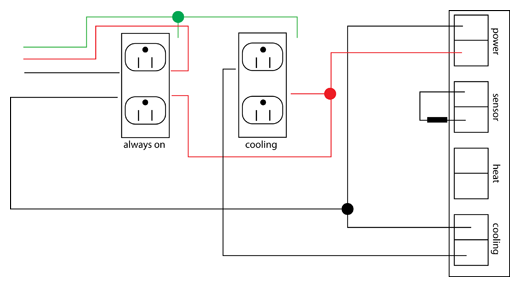

Mine is wired up to have one set of sockets always on, so I'm not tying up my wall socket all the time. I can run the vacuum if I want. Then one 2-sided outlet for heater and one 2-sided outlet for cooling.

LowNotes said:Stupid question time: Does this automatically cycle back-and-forth between heating/cooling depending on the temp the probe is exposed to, or does it requier a manual switch to change it back and forth? Seems like it would be stupid and not worth it if it ISN'T automatic...and I am 99% sure that is exaclty what was being discussed with the 3 minute delay...but I didn't see it explicitly stated (admittedly I only read piecs of the thread) and the descriptions online are terribly written. I am hoping this is "set-it and forget-it", as I might actually start making plans to make one...but if it doesn't work automatically it is definitely not going to work for me.

Stupid question time: Does this automatically cycle back-and-forth between heating/cooling depending on the temp the probe is exposed to, or does it requier a manual switch to change it back and forth? Seems like it would be stupid and not worth it if it ISN'T automatic...and I am 99% sure that is exaclty what was being discussed with the 3 minute delay...but I didn't see it explicitly stated (admittedly I only read piecs of the thread) and the descriptions online are terribly written. I am hoping this is "set-it and forget-it", as I might actually start making plans to make one...but if it doesn't work automatically it is definitely not going to work for me.

I don't have the STC (using the love TSS2) but with any controller -

use a couple of lamps - and have some warm water and ice water - then move the probe from one to the other and see if the lamps come on appropriately - that way you're not hard-cycling your compressor during the test/troubleshoot phase.

toestothesun said:Using Revvy's diagram should I wire directly to the screws of the outlets or use the holes underneath? Also, wherever same color wires cross and there is not a "squiggle" should I use wire connectors there? Is it ok to have two sets of wires going to the same outlet terminal?

Thanks in advance

In order:

I was taught to side wire all outlets (wrap around the screws) because it's a more secure connection. After seeing many many loose backwired outlets doing remodeling, and very few loose side wired, I suggest side wiring. Back wired aluminum wires actually started a fire that burned a condo I was living in to e ground. That had more to do with the aluminum wiring than how they were connected though.

Yes.

If you backwire the outlet (use the holes instead of wrapping around the screw), and the wires are the same size, then you can connect two of them to the same outlet terminal. Otherwise you'll need to connect them together with a pigtail, and then connect the pigtail wire to the terminal.

Juan, please excuse my ignorance but what exactly do you mean by pig tailing before connecting to the terminal? Is this simply wrapping the two ends of wires together? If this is what you're referring to, I did this and the wire becomes too thick to tighten down with the screw. I'm using 14 gauge power cord wire. Thanks bud

toestothesun said:Juan, please excuse my ignorance but what exactly do you mean by pig tailing before connecting to the terminal? Is this simply wrapping the two ends of wires together? If this is what you're referring to, I did this and the wire becomes too thick to tighten down with the screw. I'm using 14 gauge power cord wire. Thanks bud

So will my red wire (14 gauge - believe) wire nuts work or will I have to get a different size?

Great thread here guys, the diagrams are super helpful. I needed to temp control a mini fridge that I use for fermenting. Would love to see some picks of what you all do with the boxes once wired up. Mount them to the fridge/freezer, mount to a wall, leave em loose?

Hey guys,

I'm thinking of using an STC1000 (240v/12V) in the UK to control the temperature of an insulated area of my shed for fermentation.

Can the relays be used to switch a 12V supply? I am thinking of using a 12V PC fan and a 12V heater blanket to control the temperature of the area. The aim eventually would be to have these run from a small scale solar panel feeding into a car battery.

I know this may not be the cheapest or easiest solution but what do you all think? I'm in it for the learning experience and challenge as well! Would it be better to simply run a solution from the mains?

Cheers,

Phil

Should work fine. You'll still need to supply the controller with 240v, but the relays can switch any voltage as long as the draw isn't excessive, which shouldn't be an issue with a pc fan and small heating blanket.

Hey Revvy, what are the screw clamp connectors used for? Is that what's coming out of the side of the box?A lot of us just use a "replacement power tool cord" or even cut apart an extension cord. I usually buy larger that I need, so I can cut a few feet off to use to actually wire it.

Here's a basic parts list....

R62-16252-0WS Leviton 15-Amp White Decora Plus Duplex Outlet (as many as needed)

R52-PJ264-00W Leviton White Midway Nylon Wallplate (As many "gangs" (Slots as needed)

AW62632 Husky 9 Ft. 14-3 Power Tool Replacement Cord

B468R CARLON Electrical Wall Box (As many "gangs" as needed)

20511 Halex No. 20511, 3/8 In. Pack of 5 Twin Screw Clamp Connector

STC 1000 Dual stage temperature Controller w/probe

I based mine on Tom's design...His thread is good, I have only the slightest knowledge of doing this stuff. I can switch out a bad wall socket but that's about it. And I really didn't have trouble doing this.

In fact I just wired one up with only 3 gangs (Not an always on) and did it without a diagram.

Is it possible to attach a 120mm computer fan so that the fan only runs when the controller tells the freezer to run?

They should last longer than that. Without knowing the model, it might be lower quality, or your compressor may be overloading the relay when it kicks on causing it to fail after a while (the compressor probably only uses a few amps when running, but could pull 15 or more when it starts). Try running the compressor through a separate relay rated for a higher current and maybe that will fix the problem.Has anyone used this controller for any length of time? I bought a different model and three times as much and it lasted for a year.

Thanks, that is a great idea. I should have known better with the other one because the reviews said they would quit after about a year. I'll try this one. At this price it is worth replacing every year. I just thought maybe someone had used one for an extended time.

JuanMoore said:I have several, and the oldest has been going strong for just shy of 4 years now. The other ones have all been working for over 2 years.

Enter your email address to join: