You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your sculpture or brew rig

- Thread starter Onescalerguy

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

CollinsBrew

Well-Known Member

I'm excited that I actually get to post to this thread...holy cow it's long now!

Here it is, there's a link to my build thread in my signature:

Here it is, there's a link to my build thread in my signature:

Crimsonwine

Well-Known Member

Here is mine....

Here is mine....

Nice ! Very neat and clean.

Which chiller is that ?

Crimsonwine said:Here is mine....

Do by chance have a photo of your burner mount and kettle supports?

Crimsonwine

Well-Known Member

Nice ! Very neat and clean.

Which chiller is that ?

It is the Duda Diesel 30 plate...and man does it drop the temp fast...

Thanks for the compliment...Yes I wanted to keep it clean...I don't like clutter...

Crimsonwine

Well-Known Member

Do by chance have a photo of your burner mount and kettle supports?

I am on the road but I can get better picture of it this weekend...but here is one that might help...

It is the Duda Diesel 30 plate...and man does it drop the temp fast...

Glad to hear that. I bought the same one ! Different vendor though. I can't wait to use it.

steveoatley

someone has to fail, so the rest of you look good

SCB,

did you build the Control panel ? or did you buy if from Kal ?

Swweeeet system !!

Looks great !

Cheers

did you build the Control panel ? or did you buy if from Kal ?

Swweeeet system !!

Looks great !

Cheers

SpaceCoastBrew

Well-Known Member

Thanks steveoatley! I sourced the components and built the panel myself. I followed Kal's tutorials (they're top notch) but I made some changes to fit my needs.

steveoatley

someone has to fail, so the rest of you look good

Nice work !!!!

I hope mine turns out that nice !!

cheers

I hope mine turns out that nice !!

cheers

McCuckerson

Well-Known Member

Crimsonwine said:Here is mine....

I just chubbed

tulsabrewdaddy

Well-Known Member

that's what I did for the longest time. No shame in it! It makes beer! I was using a stainless steel table I bought at Sam's for majority of my brewing. Once I got my rig made, I moved it to the basement where I use the table as a work bench! No more working on the cement floor!

you know you're jealous! Just kiddin... gets the job done though!

Hah! Been there - and still there - 'cept more precariously than yours: I have a longer table, upon which I perch a Workmate with a Blichmann floor burner on top with my HLT, then my cooler MLT on the table, and another Blichmann burner with the leg extensions on the ground for my BK.

It's wicked pissah scary!

I'm about a third of the way through building a single tier that will finally lend some sanity to my brew days...

Cheers!

TriangleIL

Well-Known Member

Thanks to everyone who posted their beer porn for me to view. I had gotten out of the game for almost a year due to not having full time employment and no money to finish my brew rig. After a friend asked me to come by and watch him brew last weekend, I realized I shouldn't give up hope and that money will come eventually to finish the project. So I am going to wrap up the brew rig in the next few months, post pictures of the finished product and first brew day, and then be a happy beer drinking man again. Thanks for the inspiration guys!

Just completed my rig. All I have to do next is get a SS ball valve for the new keg and I am done. Here is the link.

https://cdn.homebrewtalk.com/gallery/showphoto.php?photo=49413&title=imag0510&cat=4

https://cdn.homebrewtalk.com/gallery/showphoto.php?photo=49413&title=imag0510&cat=4

Some really nice systems here... My wife and I just transitioned from extract to all grain, and here's the setup so far:

We preheat water on propane for speed. HLT is electric with ETC automation - the hand mixer rednecked on top just blew up today, but I just received a recirc pump the other day so I'll need to plumb that in before the next batch. The MLT is pretty basic - someday we might turn our immersion chiller into a HERMS coil in the HLT, but that's down the road. BK handles our 7gal. batches easy. Yes, the electrical is ghetto, made out of junk in the garage, but it's GFI - it'll be boxed and cleaned up soon.

We preheat water on propane for speed. HLT is electric with ETC automation - the hand mixer rednecked on top just blew up today, but I just received a recirc pump the other day so I'll need to plumb that in before the next batch. The MLT is pretty basic - someday we might turn our immersion chiller into a HERMS coil in the HLT, but that's down the road. BK handles our 7gal. batches easy. Yes, the electrical is ghetto, made out of junk in the garage, but it's GFI - it'll be boxed and cleaned up soon.

steveoatley

someone has to fail, so the rest of you look good

1

AstroAcks6

New Member

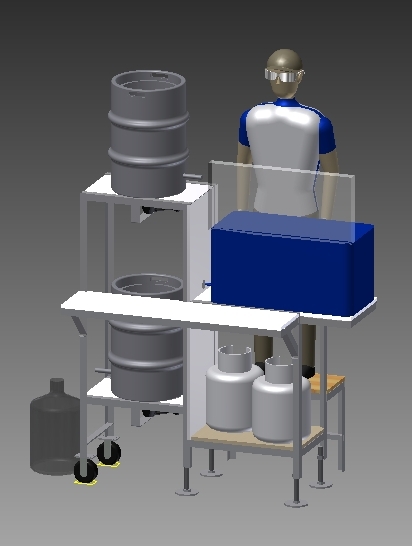

Finished the build out of harten74's three tier stand. It's not perfect and needs to be sealed, i need to add the plumbing, pump and plate chiller, but it's now been brewed on! Love this design, tweaked it slightly for my needs by it's awesome!

steveoatley

someone has to fail, so the rest of you look good

My two vessel no sparge rig...

For more info checkout my blog (linked in my sig

Woo hoo my 300th post and the 1600th reply to the thread!

Kmat123

I notice on you blog that you are pumping your wort....

recirculating during the mash & pumping your wort threw the Im. Chiller -

instead of pumping cold water threw the chiller, sitting in the wort.

I mean No dis respect... but why ?

I am looking at building a 2 vessel system myself.... and I am looking at all possibilities.

I am trying to keep everything as simple as possible, and only one pump, and only pumping one liquid keeps it simple.

But pumping the chilling water threw the Im. Chiller is a way to clean out the chiller....?

I am just looking for all ideas.

thanks

Snafu

Well-Known Member

Here's my current set up.

And when its time to fly sparge I just connect the "sparge do-dad" and move the MLT up onto the HLT.

Fresh water provide by in line filter

And lastly, the chiller

And when its time to fly sparge I just connect the "sparge do-dad" and move the MLT up onto the HLT.

Fresh water provide by in line filter

And lastly, the chiller

Kmat123

I notice on you blog that you are pumping your wort....

recirculating during the mash & pumping your wort threw the Im. Chiller -

instead of pumping cold water threw the chiller, sitting in the wort.

I mean No dis respect... but why ?

I am looking at building a 2 vessel system myself.... and I am looking at all possibilities.

I am trying to keep everything as simple as possible, and only one pump, and only pumping one liquid keeps it simple.

But pumping the chilling water threw the Im. Chiller is a way to clean out the chiller....?

I am just looking for all ideas.

thanks

Hey Steve,

I originally tried cooling by pumping ice water through the immersion coil in the BK but this took about 40 min to bring the wort from boiling to pitching temps. On the next brew day I decided to place the IC in the cooler filled with first 10 gallons of cold tap water (which brings the temp down to around 105-110 degrees) and then 10 gallons of ice water (I simply empty the ice cube tray out of my freezer). Using this method I was able to go from boiling to 66 degrees in 20 min (using only 20 gallons of water).

I recirculate through the IC for the last 10 minutes of the boil to sanitize everything. Then once I have drained my BK I switch the hose coming out of my BK to my cooler and clear the lines. This system has worked great for me an I love the simplicity of no sparge brewing. I have been consistently hitting efficiencies of 70-75%

steveoatley

someone has to fail, so the rest of you look good

Hey Steve,

I originally tried cooling by pumping ice water through the immersion coil in the BK but this took about 40 min to bring the wort from boiling to pitching temps. On the next brew day I decided to place the IC in the cooler filled with first 10 gallons of cold tap water (which brings the temp down to around 105-110 degrees) and then 10 gallons of ice water (I simply empty the ice cube tray out of my freezer). Using this method I was able to go from boiling to 66 degrees in 20 min (using only 20 gallons of water).

I recirculate through the IC for the last 10 minutes of the boil to sanitize everything. Then once I have drained my BK I switch the hose coming out of my BK to my cooler and clear the lines. This system has worked great for me an I love the simplicity of no sparge brewing. I have been consistently hitting efficiencies of 70-75%

Kmat123

Do you think there would be any issues with me using a Copper Im. Chiller ?

Any sanitary issues ?

Thanks for the help + I will stop highjacking the thread !

Cheers

I would post my picture....but a bucket & pot do not make a cool sculpture !

Kmat123

Do you think there would be any issues with me using a Copper Im. Chiller ?

Any sanitary issues ?

Thanks for the help + I will stop highjacking the thread !

Cheers

I would post my picture....but a bucket & pot do not make a cool sculpture !

A cooper immersion chiller should work great and you might actually get better heat exchange than with a SS coil like I have.

TriangleIL

Well-Known Member

Here is mine....

Very nice looking setup you have there. Are you in downtown?

Crimsonwine

Well-Known Member

Very nice looking setup you have there. Are you in downtown?

Thanks for the compliment...No I am actually out by Oak Lawn....Harlem and 95th

Islandboy85

Well-Known Member

This is my brewing rig. My HLT is a rectangular cooler on two saw horses that will soon be upgraded with a dishwasher pump for sparking or replaced by a Corey keg. It's hard to get decent flow into my rotating sparge arm with high gravity ten gallon batches because there is little head pressure from the HLT to the sparge arm. Anyway, its a direct fire recirculating mash system. I'm quite happy with it. Some point I may go electric, like when I get a house... The biggest issue for me brewing right now is setup and tear down. I have to haul all the equipment over the wall or through the apartment outside to a garage. I'm probably going to buy one of those rolling carts from Harbor Freight so I can county burner, the propane tank, a hose real, a pump mount, and strap the two kegs onto it , for transport to and from the garage. If all I've got o do is haul the cooler HLT or a Corey keg HLT separate from the rest of the brewing equipment than that will save me an easy 30 min setting up. My back will sure love it too.

http://s924.photobucket.com/albums/ad81/islandboy85/?action=view¤t=IMAG0536.jpg

This is my first recipe I've designed myself. It's my 10th batch.

My List IPA. 30.5# grain bill.

http://s924.photobucket.com/albums/ad81/islandboy85/?action=view¤t=IMAG0933.jpg

http://s924.photobucket.com/albums/ad81/islandboy85/?action=view¤t=IMAG0536.jpg

This is my first recipe I've designed myself. It's my 10th batch.

My List IPA. 30.5# grain bill.

http://s924.photobucket.com/albums/ad81/islandboy85/?action=view¤t=IMAG0933.jpg

brandolomite

Active Member

Fresh from the powder coater. Built this last year and have brewed about a dozen batches on it but finally got it painted and added some fresh bling! I really liked the front control panel design from nicksteck and the detailed instructions at theelectricbrewery.com were a huge help.

hawgwild81

Well-Known Member

brandolomite said:Fresh from the powder coater. Built this last year and have brewed about a dozen batches on it but finally got it painted and added some fresh bling! I really liked the front control panel design from nicksteck and the detailed instructions at theelectricbrewery.com were a huge help.

That's awesome! I'm jealous. Wish I could do something like that.

Fresh from the powder coater. Built this last year and have brewed about a dozen batches on it but finally got it painted and added some fresh bling! I really liked the front control panel design from nicksteck and the detailed instructions at theelectricbrewery.com were a huge help.

I am speechless. Hope you are able to post some more pics. I would love to see a few close ups and maybe a peek under the hood! It's gotta be to tough to focus on brewing haha

Similar threads

- Replies

- 4

- Views

- 693

- Replies

- 2

- Views

- 1K