spearko520

Well-Known Member

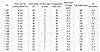

Does anyone have any formulas to determine flow rate for oxygen? I have charts indicating what rates (in liters/min- i can convert that to cfm- i think) are required to reach suggested O2 ratios in ppm. The physical data i would have would be the psi of my gauge on bottle and discharge side, the outlet diameter and length of the discharge tubing, and the atmospheric pressure at point of discharge. There probably should be some sort of co effecient in there for the characteristics of the stone itself, but i figured i'd start with the open end of the hose first, since maybe the stone manufacturer calculated that into the flow rates they suggest on their table. Short of putting a flow meter in line and maybe marking some numbers on my gauges, does anyone know some sort of formula to figure all this out? Thanks in advance!!!