I have been actually making progress on my home brewery and wanted to setup a post here so people can add pointers on things to change due to experience....

I went to school for chemical engineering and now i use very little of the skills that I learned at work so I needed a big project at home to actually flex my engineering skills. What better than an automated electric brewery where I do as much of the design and programing myself as is reasonable for a married dude with 2 children. Overall plan is to follow Kal's website and setup an all grain electric brewery in my garage.

anyway some pictures

Brewing table I built

with 3 20 gallon 304SS kettles bought from my local homebrew shop http://www.brewbrothers.biz/

I also punched some holes in the kettles last year... and snagged a bunch of fittings from http://www.bargainfittings.com/ then we had our second little girl and I had no time... fast forward to a few months ago when i found some time.

Picked up some tri-clamp element adapters from brewers hardware. This is an awesome way to mount electrical heating elements to your kettles... but of course I picked these up after I bought rippled heating elements which don't fit through the enclosure without lots of bending. So I also snagged 2 straight 5500W ULWD elements which fit nicely.

https://www.brewershardware.com/TC15F10NPSCOV.html

Took the HLT and BK to a local welding shop and got some stubby 1.5" tri-clamp ferrules welded on. I had already used a 1-1/4" punch to make holes in both as I was going with Kal's mounting method, so I had the shop widen the hole and weld the ferrule flush with the inner wall of the kettle. They charged me $100 for 2 fittings so I think I was overcharged.... I found a guy in Portland on Craigslist that will do the work for $30 a hole from the pics he's a better welder too. I will look him up when I start upgrading the rest of my fittings to triclamp... but that's a bit down the road.

http://portland.craigslist.org/mlt/for/3847525286.html

Found a really nice 42" range hood on craigslist that I've badly mounted in the garage... but hell it's secure, and it actually came out level so I'm happy.

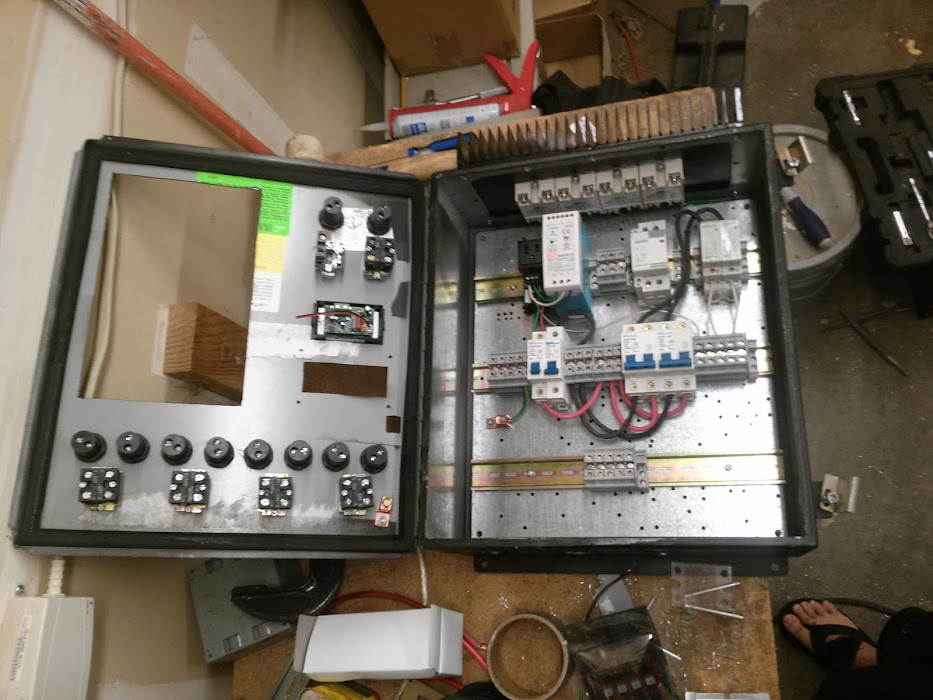

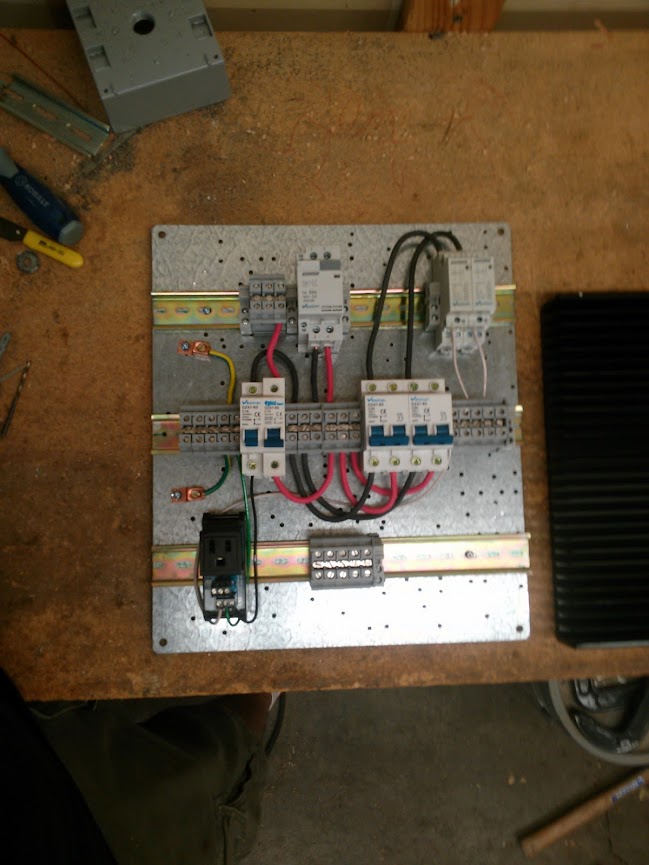

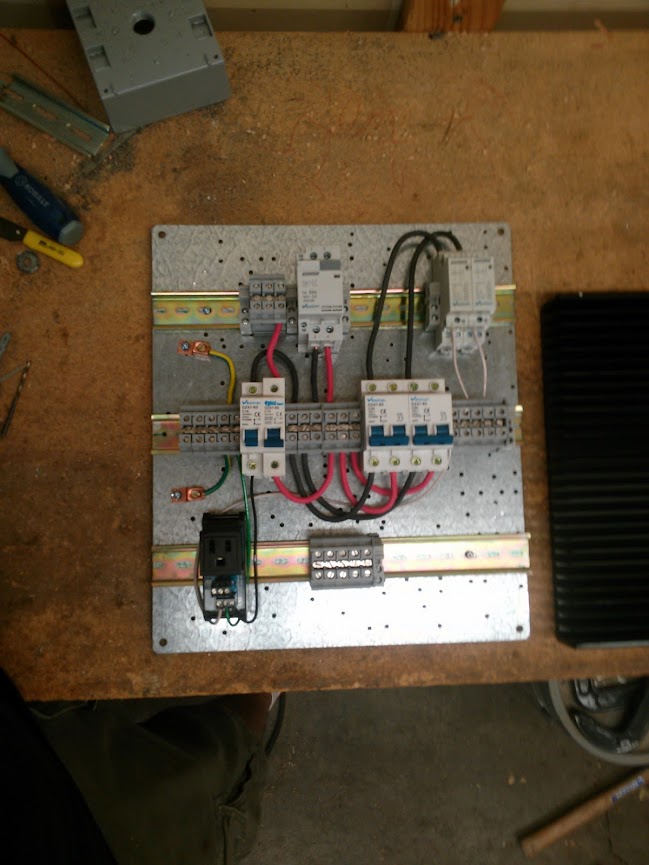

Picked up a really nice DIN mount control panel kit from Electric Brewing Supply. This kit is wonderful and inexpensive relative to what i was looking at piecing together the same components from other sites. This is the BCS kit, though I don't have a BCS it is generic for any control system. Also, I have the 50A kit as I plan on starting the cleaning cycle by heating cleaning fluid in the HLT while the boil is going.

http://www.ebrewsupply.com/ebrew-kits/bcs-2-element-2-pumps-50a-kit.html

And wandered to the local industrial surplus store and found a good deal on a enclosure

https://www.surplusgizmos.com/

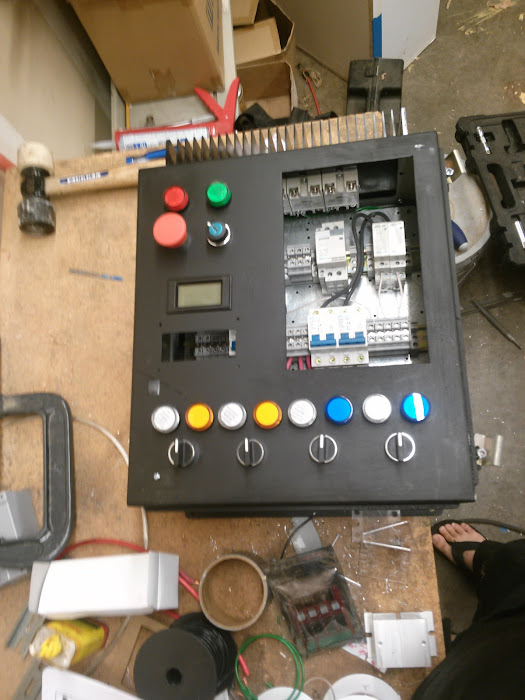

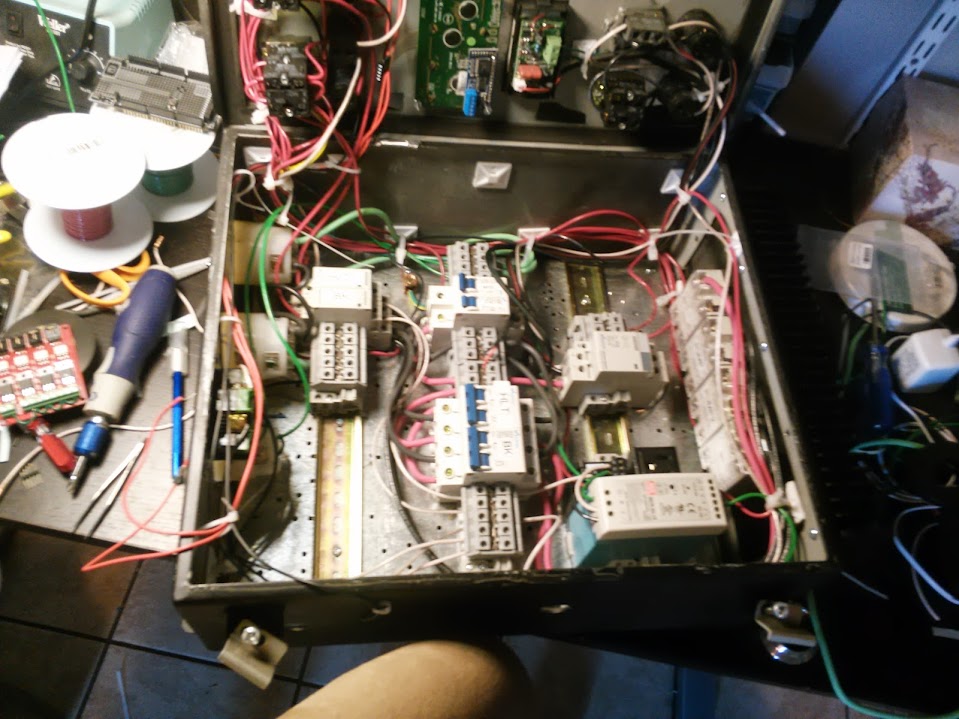

so now I have some basic progress on a control panel. You can see the large heatsink just off to the side that will be used to dissipate heat off the SSRs

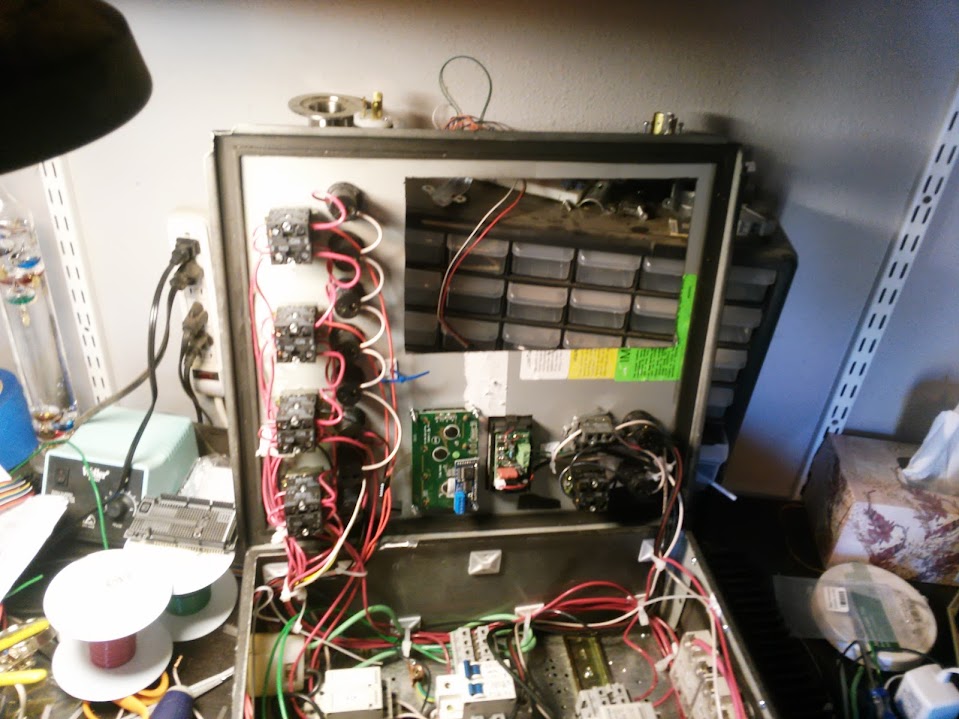

I still have to make a cutout for my 20X4 character LCD display for my Arduino and I found a cheep Chinese combo V/A meter on ebay.

http://www.ebay.com/itm/Digital-AC-...681?pt=LH_DefaultDomain_0&hash=item35c7283119

I currently am developing on an Arduino Mega ADK, which has USB host functionality. At first I entertained the Idea of developing an Android application to control the brewery from an Android tablet, but with my limited programing experience writing up an Android app is a bit over my head a the moment. Also, writing for Android would restrict my options for control platforms so my eventual goal is to host a website on the local network. So instead I have an old 10" Dell Atom based tablet that neither the wife nor I use anymore that I will be mounting to the open area on the upper right of the control panel and use as the front end for the Arduino. The tablet will be running code I've written in Processing, which is an open sourced java based programing language which an emphasis on generating visual interaction.

Plan for this weekend is to finish up cutting holes in the control panel and hopefully finishing wiring up. Then I can work on stuffing the Arduino in. I hope to be actually heating water before the end of the month.

I'd like to thank Kal for his wonderful website that has guided me through making a all electric setup

http://www.theelectricbrewery.com/

and Open Source Control Systems for providing software inspiration for many little things in my code which is nowhere near functional yet

https://www.oscsys.com/

I went to school for chemical engineering and now i use very little of the skills that I learned at work so I needed a big project at home to actually flex my engineering skills. What better than an automated electric brewery where I do as much of the design and programing myself as is reasonable for a married dude with 2 children. Overall plan is to follow Kal's website and setup an all grain electric brewery in my garage.

anyway some pictures

Brewing table I built

with 3 20 gallon 304SS kettles bought from my local homebrew shop http://www.brewbrothers.biz/

I also punched some holes in the kettles last year... and snagged a bunch of fittings from http://www.bargainfittings.com/ then we had our second little girl and I had no time... fast forward to a few months ago when i found some time.

Picked up some tri-clamp element adapters from brewers hardware. This is an awesome way to mount electrical heating elements to your kettles... but of course I picked these up after I bought rippled heating elements which don't fit through the enclosure without lots of bending. So I also snagged 2 straight 5500W ULWD elements which fit nicely.

https://www.brewershardware.com/TC15F10NPSCOV.html

Took the HLT and BK to a local welding shop and got some stubby 1.5" tri-clamp ferrules welded on. I had already used a 1-1/4" punch to make holes in both as I was going with Kal's mounting method, so I had the shop widen the hole and weld the ferrule flush with the inner wall of the kettle. They charged me $100 for 2 fittings so I think I was overcharged.... I found a guy in Portland on Craigslist that will do the work for $30 a hole from the pics he's a better welder too. I will look him up when I start upgrading the rest of my fittings to triclamp... but that's a bit down the road.

http://portland.craigslist.org/mlt/for/3847525286.html

Found a really nice 42" range hood on craigslist that I've badly mounted in the garage... but hell it's secure, and it actually came out level so I'm happy.

Picked up a really nice DIN mount control panel kit from Electric Brewing Supply. This kit is wonderful and inexpensive relative to what i was looking at piecing together the same components from other sites. This is the BCS kit, though I don't have a BCS it is generic for any control system. Also, I have the 50A kit as I plan on starting the cleaning cycle by heating cleaning fluid in the HLT while the boil is going.

http://www.ebrewsupply.com/ebrew-kits/bcs-2-element-2-pumps-50a-kit.html

And wandered to the local industrial surplus store and found a good deal on a enclosure

https://www.surplusgizmos.com/

so now I have some basic progress on a control panel. You can see the large heatsink just off to the side that will be used to dissipate heat off the SSRs

I still have to make a cutout for my 20X4 character LCD display for my Arduino and I found a cheep Chinese combo V/A meter on ebay.

http://www.ebay.com/itm/Digital-AC-...681?pt=LH_DefaultDomain_0&hash=item35c7283119

I currently am developing on an Arduino Mega ADK, which has USB host functionality. At first I entertained the Idea of developing an Android application to control the brewery from an Android tablet, but with my limited programing experience writing up an Android app is a bit over my head a the moment. Also, writing for Android would restrict my options for control platforms so my eventual goal is to host a website on the local network. So instead I have an old 10" Dell Atom based tablet that neither the wife nor I use anymore that I will be mounting to the open area on the upper right of the control panel and use as the front end for the Arduino. The tablet will be running code I've written in Processing, which is an open sourced java based programing language which an emphasis on generating visual interaction.

Plan for this weekend is to finish up cutting holes in the control panel and hopefully finishing wiring up. Then I can work on stuffing the Arduino in. I hope to be actually heating water before the end of the month.

I'd like to thank Kal for his wonderful website that has guided me through making a all electric setup

http://www.theelectricbrewery.com/

and Open Source Control Systems for providing software inspiration for many little things in my code which is nowhere near functional yet

https://www.oscsys.com/