There is a guy who does it, and has a thread somewhere. He keeps his chamber (fridge, chest freezer, or ?, can't remember) super cold, around 40F, I think, and the fermwraps have no issues keeping up. The 40F is more than enough to keep up with any fermentation. He didn't mess with trying to cool to one specific fermenter, he just used fermwraps (cheap DIY version) on everything. I think he used PIDs for the fermwraps, but any controller can have the diff set to min, even 0.1F, without any real issues. There is no compressor to worry about, and the relay should be able to handle the cycling for years.I was planning to do something like this but was unsure of its feasibility. My plan was to control the chamber itself (cooling) with a probe on the fermentor that I want to have the lowest temp, and fermwraps on everything else, in order to be able to specifically control different fermentations exactly how I want, in a single chamber. I'm a bit concerned that I might not be able to get a significant difference in temp between the coolest and warmest fermentations though. Thoughts?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ebay aquarium temp controller build

- Thread starter android

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jeepinjeepin

Well-Known Member

Why do I think I've heard that fermwraps are good for a 15 degrees rise? Has anyone else heard that or feel like looking it up?

Why do I think I've heard that fermwraps are good for a 15 degrees rise? Has anyone else heard that or feel like looking it up?

http://fermentap.com/view_product/16674/100573

(Sic)In an unenclosed evironment we see a heating differential between carboy and ambient of 10-15 degrees

Maybe he keeps his chamber at 50F, since that should be able to keep up with a 5-6G ferm. I thought he kept it colder, which is why I prefaced it that way. The guy has a thread about, or posted his method (with pics) in a related thread started by someone else (maybe about DIY fermwraps). He seemed happy with it, and had done some temp verification. I will see if I can find the thread.Why do I think I've heard that fermwraps are good for a 15 degrees rise? Has anyone else heard that or feel like looking it up?

Swapping the controller's sensor to the newest/most active ferm would keep ambient temps as warm as is possible, to prevent overloading the fermwraps. It does complicate the control scheme, though. If the external ambient gets colder than what is required for the active ferm, or colder than what the fermwraps can compensate for, you would need an additional heat source for the internal ambient, probably with another controller. It seems like there are scenarios where using the dual stage's heat output, when sensing the most active ferm for refrigeration/heating, could let the ambient go below the min temp the fermwraps could handle.

Charlieatthedisco

Well-Known Member

anyone have a schematic to just use one outlet for cooling? I read an earlier post but did not understand it...help!

jeepinjeepin

Well-Known Member

Charlieatthedisco said:anyone have a schematic to just use one outlet for cooling? I read an earlier post but did not understand it...help!

Like, both outlets on one receptacle for cooling only? Just don't break the tab on the side and ignore the heater wires.

Charlieatthedisco

Well-Known Member

Thanks! I figured it out and it works perfectly! Has anyone had any issues putting a bead of silicone caulking around the box of the controller? For those of you that mounted it in your keezer collar

barryfine

Well-Known Member

Using separate DIY fermwraps and controllers for the least active ferms would keep ferm temps much more stable. There is no way to control more than one fermentation in a single chamber without using this method, or its equivalent. Peak ferm temp is ~10F above ambient. The fan will help reduce that differential some, but even if all but one are in the clean up phase, the temps in those will be dropping, possibly causing the yeast to slow down. Probably not a huge issue if all but one is finished, but a much bigger issue if two are going at once that were pitched a few days apart.

Those were all brewed and pitched on the same day so keeping the temp of one of them in the proper range should keep them all at the right temp, give or take a degree or two. I have other chambers for beers that are brewed and pitched on different days to keep the ones that are actively fermenting aways from those that are just aging. Thanks for the input though.

FuzzeWuzze

I Love DIY

Thanks! I figured it out and it works perfectly! Has anyone had any issues putting a bead of silicone caulking around the box of the controller? For those of you that mounted it in your keezer collar

Mounting the entire unit inside the keezer? I would be worried about condensation more than anything, one atom of water hits anywhere between contacts of the switches inside and its toast.

zachattack

Well-Known Member

- Joined

- Mar 6, 2012

- Messages

- 2,808

- Reaction score

- 323

Mounting the entire unit inside the keezer? I would be worried about condensation more than anything, one atom of water hits anywhere between contacts of the switches inside and its toast.

So you run yours at 0% relative humidity? Like in a vacuum chamber? That's the only way to have zero atoms of water

There are electronics mounted inside many fridges, including from the factory. You just have to keep it sealed up to prevent condensation, so having it inside the keezer is fine as long as it's not exposed. Also, since it's going to be one of the warmer surfaces in the keezer there shouldn't be any water continuously condensing on the unit itself. Generally you just see condensation on the walls and it pools down onto the floor.

Mine's mounted inside an outlet junction box (look for the "ebay controller build with walmart parts" thread). It's sealed up with caulk and mounted through the collar.

jeepinjeepin

Well-Known Member

Non-condensing is the key

I wouldn't trust that controlling one will control the others. Even using the same yeast, one could easily peak 12 hours before the others. The temp variance might be < 2F, or it might be more. Using different yeasts for each split of the batch could easily result in a 24 hour, or more, difference in peaks.Those were all brewed and pitched on the same day so keeping the temp of one of them in the proper range should keep them all at the right temp, give or take a degree or two.

I decided to go with the space heater recommendations. Will be ordering one of these later today. (http://www.amazon.com/gp/product/B003XDTWN2/?tag=skimlinks_replacement-20)

Last edited by a moderator:

sirmichael

Well-Known Member

- Joined

- Feb 4, 2012

- Messages

- 109

- Reaction score

- 11

barryfine

Well-Known Member

I wouldn't trust that controlling one will control the others. Even using the same yeast, one could easily peak 12 hours before the others. The temp variance might be < 2F, or it might be more. Using different yeasts for each split of the batch could easily result in a 24 hour, or more, difference in peaks.

Sure, there are always better ways to do something, but for $13 the heater is doing just fine.

barryfine

Well-Known Member

I decided to go with the space heater recommendations. Will be ordering one of these later today. (http://www.amazon.com/gp/product/B003XDTWN2/?tag=skimlinks_replacement-20)

I found one of those at Walmart for $13.

Last edited by a moderator:

I found one of those at Walmart for $13.

It appears to have gone up since you bought it. It lists for $18 on their site. I couldn't find a cheaper model of space heater anywhere.

http://www.walmart.com/ip/Lasko-Products-My-Heat-Personal-Heater/16503222

The price of air conditioners drops in the winter and the price of heaters drops in the summer. Basic economics.It appears to have gone up since you bought it. It lists for $18 on their site. I couldn't find a cheaper model of space heater anywhere.

http://www.walmart.com/ip/Lasko-Products-My-Heat-Personal-Heater/16503222

barryfine

Well-Known Member

The price of air conditioners drops in the winter and the price of heaters drops in the summer. Basic economics.

I don't know. I just bought it last week. Maybe the in store price is lower or this one might be a different model.

Anyone know if the STC-1000 will push enough amps to start up a Holiday 7cu chest freezer set up in my garage?

Here are some specs from the back of the freezer:

Voltage: 115v~60Hz

Amps:1.70A

Startup Amps: 12A

Here are some specs from the back of the freezer:

Voltage: 115v~60Hz

Amps:1.70A

Startup Amps: 12A

jeepinjeepin

Well-Known Member

fwooten said:Anyone know if the STC-1000 will push enough amps to start up a Holiday 7cu chest freezer set up in my garage?

Here are some specs from the back of the freezer:

Voltage: 115v~60Hz

Amps:1.70A

Startup Amps: 12A

It should... Some users have reported that the relays are good up to 15A@120VAC. Worst case scenario has you adding a single SSR for just a few more dollars. Wiring that is similar but easier than the STC-1000 project if it comes down to it.

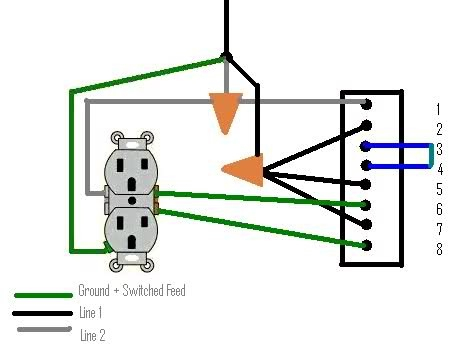

Here is a photo from another thread.

It should... Some users have reported that the relays are good up to 15A@120VAC. Worst case scenario has you adding a single SSR for just a few more dollars. Wiring that is similar but easier than the STC-1000 project if it comes down to it.

Here is a photo from another thread.

Whats that other thread?

jeepinjeepin

Well-Known Member

fwooten said:Whats that other thread?

There are a few now.

I think this is the original. https://www.homebrewtalk.com/f51/ebay-fish-tank-controller-build-using-wal-mart-parts-261506/

And here is another.

https://www.homebrewtalk.com/f51/stc-1000-wiring-333680/

It was more for the benefit of the greater community. If the finer points aren't included/listed, someone will just go off the picture, and think it is 'the way' to do it with no downsides.Sure, there are always better ways to do something, but for $13 the heater is doing just fine.

marshallwms

Junior Member

For heat in my fermentation chamber, I have just been using an old soldering in a holder and a 12V fan. I like having a fan on at all times to keep condensation down and temperatures more stable inside the box.

My STC-1000 and my single stage controller were ordered over a month ago. PayPal / eBay managed somehow to send them both (ordered within 5 minutes of each other) to an eleven year old address. The boxes were refused, one going back to Hong Kong, one re-delivered to the wrong address. That is the STC-1000 and it made it to me. The owner of the house it was delivered to knows who I am. One of the club members works for him, and he knows that, too. After the club member asked about the mis-delivered / refused items, they somehow managed to get the re-delivered one to him. It took them no effort whatsoever. Between stupid people and incompetent eBay, this has been a real mess.

My STC-1000 and my single stage controller were ordered over a month ago. PayPal / eBay managed somehow to send them both (ordered within 5 minutes of each other) to an eleven year old address. The boxes were refused, one going back to Hong Kong, one re-delivered to the wrong address. That is the STC-1000 and it made it to me. The owner of the house it was delivered to knows who I am. One of the club members works for him, and he knows that, too. After the club member asked about the mis-delivered / refused items, they somehow managed to get the re-delivered one to him. It took them no effort whatsoever. Between stupid people and incompetent eBay, this has been a real mess.

For heat in my fermentation chamber, I have just been using an old soldering in a holder and a 12V fan. I like having a fan on at all times to keep condensation down and temperatures more stable inside the box.

My STC-1000 and my single stage controller were ordered over a month ago. PayPal / eBay managed somehow to send them both (ordered within 5 minutes of each other) to an eleven year old address. The boxes were refused, one going back to Hong Kong, one re-delivered to the wrong address. That is the STC-1000 and it made it to me. The owner of the house it was delivered to knows who I am. One of the club members works for him, and he knows that, too. After the club member asked about the mis-delivered / refused items, they somehow managed to get the re-delivered one to him. It took them no effort whatsoever. Between stupid people and incompetent eBay, this has been a real mess.

Thanks. This is just what I need to hear. Ive got a STC 1000 enroute form Hong Kong and I've been three weeks waiting. Should have bought in-country.

sinisterkid

Well-Known Member

I use an tin coffee can and a small aluminum shop light with a 60 watt bulb for my heat, works great

marshallwms

Junior Member

The STC-1000 was ordered from MixTea and was shipped quickly, given a tracking number which worked fine, and delivery was attempted but initially refused. It was not a problem on the seller's end, strictly an eBay / PayPal problem. They provided the seller with an address that I haven't used in over 11 years. And I have received items via eBay from sellers in China at my current address in the past. eBay really messed up. I do recommend MixTea.

zachattack

Well-Known Member

- Joined

- Mar 6, 2012

- Messages

- 2,808

- Reaction score

- 323

Not to sound like a jerk, but when you pay w/ Paypal it clearly shows you the shipping address and allows you to change it. You can't blame e-bay or Paypal if you didn't enter the newest one. I've done that by accident in the past, I only blame myself. It's not like they'd pull some ancient address out of their system and slap it on the order for no reason, the seller sees what you sent via Paypal and nothing else. Ebay may have its fair share of problems, and I know there are plenty of reasons to hate Paypal, but this isn't one of them.

marshallwms

Junior Member

Not to sound like a jerk, but when you pay w/ Paypal it clearly shows you the shipping address and allows you to change it. You can't blame e-bay or Paypal if you didn't enter the newest one. I've done that by accident in the past, I only blame myself. It's not like they'd pull some ancient address out of their system and slap it on the order for no reason, the seller sees what you sent via Paypal and nothing else. Ebay may have its fair share of problems, and I know there are plenty of reasons to hate Paypal, but this isn't one of them.

Pulling that address out for no known reason is exactly what they did. The PayPal and eBay reps had no idea how it could have happened. My shipping address in my profile was correct. I know the seller only sees what PayPal sends them. Yes, PayPal shows me the shipping address. I looked at it. I cannot prove it was the correct one when I hit submit, but I looked at it. And it HAS been the correct one for over 10 years. Anyway, this is offtopic so I won't comment / complain / carp anymore.

zachattack

Well-Known Member

- Joined

- Mar 6, 2012

- Messages

- 2,808

- Reaction score

- 323

Pulling that address out for no known reason is exactly what they did. The PayPal and eBay reps had no idea how it could have happened. My shipping address in my profile was correct. I know the seller only sees what PayPal sends them. Yes, PayPal shows me the shipping address. I looked at it. I cannot prove it was the correct one when I hit submit, but I looked at it. And it HAS been the correct one for over 10 years. Anyway, this is offtopic so I won't comment / complain / carp anymore.

Well in that case I apologize for accusing you! It's just too common these days for people to assign blame to web sites / computer programs when it's really user error, it's becoming a pet peeve of mine. I'll add that to the long list of reasons to dislike Paypal. If only there were a universally accepted alternative...

OK, back on topic. My STC-1000 has done a fantastic job keeping my kegs at the right temperature

Soldering irons are not designed to run continuously. For safety I would recommend using a different heat source.marshallwms said:For heat in my fermentation chamber, I have just been using an old soldering in a holder and a 12V fan.

Smashing

Well-Known Member

I'm in thread hell here. Are there any diagrams to use a single receptacle but only use half switched and the other half be always hot? I'm sure it's out there somewhere but my eyes are starting to bleed from searching. Thanks!!!

jeepinjeepin

Well-Known Member

Smashing said:I'm in thread hell here. Are there any diagrams to use a single receptacle but only use half switched and the other half be always hot? I'm sure it's out there somewhere but my eyes are starting to bleed from searching. Thanks!!!

I assume you are running the cooling side plus a fan or something? Wire the controller exactly as it is described here EXCEPT instead of going through the heating relay on the STC-1000 go straight to the outlet.

Smashing

Well-Known Member

I assume you are running the cooling side plus a fan or something? Wire the controller exactly as it is described here EXCEPT instead of going through the heating relay on the STC-1000 go straight to the outlet.

Exactly. So I should run hot leads from "inbound" to #1, #7 and to brass side of outlet?

Side question - does breaking the side tabs affect the push in connectors on the back of the outlet or those separate?

jeepinjeepin

Well-Known Member

Smashing said:Exactly. So I should run hot leads from "inbound" to #1, #7 and to brass side of outlet?

Side question - does breaking the side tabs affect the push in connectors on the back of the outlet or those separate?

I like this diagram better. Black is hot. Run it to 2, 5, and one side of the broken tab.

- Joined

- Jan 18, 2011

- Messages

- 3,030

- Reaction score

- 282

I like this diagram better. Black is hot. Run it to 2, 5, and one side of the broken tab.

Heheheh I scribbled that one nearly 2 years ago

MC

mouthfullofbeer

Member

this is probably the 100th time someone has said this, but has anyone come across a step by step (in laymans terms) where they've provided pictures mounting in the collar PLUS adding an AC 110V fan inside the keezer? there are just too many pages to read and i'm going cross-eyed..

thanks for your help this is great info

thanks for your help this is great info

buzzman003

Well-Known Member

I wish a mod would sticky a post or two with the best info on this topic. Seems like every week someone has the same problem.

Similar threads

- Replies

- 14

- Views

- 1K