diverpat

Well-Known Member

I'm going to attempt to brew a beer with an OG of around 1.150. I have come up with a game plan for brewing/fermentation and would like some input from those with experience. A lot of this is thinking out loud so the protocol is not set in stone.

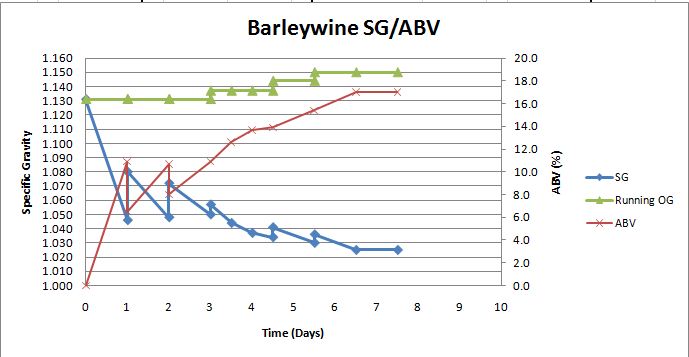

The recipe is a Barleywine but big, I'll post the recipe below. I'm planning on using WLP007 which will hopefully, under optimal conditions, be able to take this to around 15%. Beersmith says 18% but I don't think it will hit the estimated FG (1.017). I'm only doing a 3 gallon batch. Here are the steps I'm planning.

-Making a starter/sacrificial brew of 3 gallons out of some old LME. Stopping the growth at 3 days. I'll pitch my high gravity wort on this.

-Mashing long and low, 148 for 2 hours.

-Brew the planned wort and split it into (3) 1 gallon batches, oxygenating 1 gallon for around 5 minutes and pitching onto yeast cake.

-After 24 hours, oxygenate another gallon of wort and pitch, wait another 24 hours oxygenate the last gallon and pitch to get to the final volume. I'll add servomyces at each wort addition. I'm leery of oxygenating fermenting wort but there will still be some cell growth so I think it is right ?

-Keep in primary for 2 months, rack to secondary to get off of exhausted yeast and age for another 2-3 months then add yeast bottle and wait another 6-8 months before enjoying/choking down/dumping.

What do you think? What can I modify to get the best results?

Here is the recipe:

Recipe Specifications

--------------------------

Batch Size (fermenter): 3.00 gal

Boil Size: 6.00 gal

Bottling Volume: 3.00 gal

Estimated OG: 1.152 SG

Estimated Color: 25.9 SRM

Estimated IBU: 86.5 IBUs

Brewhouse Efficiency: 65.00 %

Boil Time: 120 Minutes

Ingredients:

------------

Amt Name

13 lbs Pale Malt (2 Row) US (2.0 SRM)

2 lbs Munich Malt - 10L (10.0 SRM)

1 lbs Aromatic Malt (26.0 SRM)

1 lbs Caramel/Crystal Malt - 40L (40.0 SRM)

8.0 oz Caramel/Crystal Malt - 80L (80.0 SRM)

1.00 oz Chinook [13.00 %] - Boil 60.0 min

1.00 oz Northern Brewer [8.50 %] - Boil 20.0 min

1.00 oz Northern Brewer [8.50 %] - Boil 5.0 min

1 lbs Caramel, Sugar, Table (Sucrose)

1.0 pkg Dry English Ale (White Labs #WLP007)

Mash Schedule: Single Infusion, Light Body, Batch Sparge

Total Grain Weight: 18 lbs 8.0 oz

----------------------------

Name Description Step Temperat Step Time

Mash In Add 21.88 qt of water at 158.8 F 148.0 F 120 min

The recipe is a Barleywine but big, I'll post the recipe below. I'm planning on using WLP007 which will hopefully, under optimal conditions, be able to take this to around 15%. Beersmith says 18% but I don't think it will hit the estimated FG (1.017). I'm only doing a 3 gallon batch. Here are the steps I'm planning.

-Making a starter/sacrificial brew of 3 gallons out of some old LME. Stopping the growth at 3 days. I'll pitch my high gravity wort on this.

-Mashing long and low, 148 for 2 hours.

-Brew the planned wort and split it into (3) 1 gallon batches, oxygenating 1 gallon for around 5 minutes and pitching onto yeast cake.

-After 24 hours, oxygenate another gallon of wort and pitch, wait another 24 hours oxygenate the last gallon and pitch to get to the final volume. I'll add servomyces at each wort addition. I'm leery of oxygenating fermenting wort but there will still be some cell growth so I think it is right ?

-Keep in primary for 2 months, rack to secondary to get off of exhausted yeast and age for another 2-3 months then add yeast bottle and wait another 6-8 months before enjoying/choking down/dumping.

What do you think? What can I modify to get the best results?

Here is the recipe:

Recipe Specifications

--------------------------

Batch Size (fermenter): 3.00 gal

Boil Size: 6.00 gal

Bottling Volume: 3.00 gal

Estimated OG: 1.152 SG

Estimated Color: 25.9 SRM

Estimated IBU: 86.5 IBUs

Brewhouse Efficiency: 65.00 %

Boil Time: 120 Minutes

Ingredients:

------------

Amt Name

13 lbs Pale Malt (2 Row) US (2.0 SRM)

2 lbs Munich Malt - 10L (10.0 SRM)

1 lbs Aromatic Malt (26.0 SRM)

1 lbs Caramel/Crystal Malt - 40L (40.0 SRM)

8.0 oz Caramel/Crystal Malt - 80L (80.0 SRM)

1.00 oz Chinook [13.00 %] - Boil 60.0 min

1.00 oz Northern Brewer [8.50 %] - Boil 20.0 min

1.00 oz Northern Brewer [8.50 %] - Boil 5.0 min

1 lbs Caramel, Sugar, Table (Sucrose)

1.0 pkg Dry English Ale (White Labs #WLP007)

Mash Schedule: Single Infusion, Light Body, Batch Sparge

Total Grain Weight: 18 lbs 8.0 oz

----------------------------

Name Description Step Temperat Step Time

Mash In Add 21.88 qt of water at 158.8 F 148.0 F 120 min