anonymousbrew

Well-Known Member

So the time has finally come to stop drooling and start building!

Without too much background, we recently moved into a new house, and of course one of my requirements was to have a dedicated brewing space...(to be honest, it was one of SWMBO's top requirements )

)

Our new house has a 10x16 building in back that the new brewery will be going into, but not before the new system gets built and ready to go.

So lets get to it!

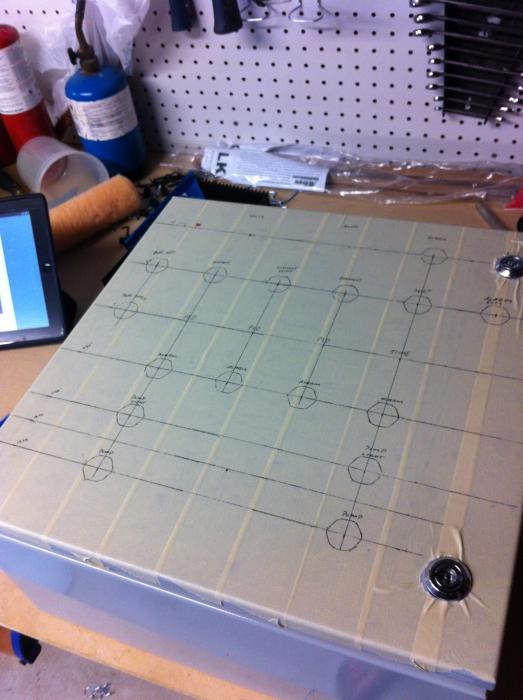

Need to upgrade my existing 3 vessel hybrid system to all electric. I've been lusting after Kal's Electric Brewery for a long time, and pulled the trigger on the DIY kit. Needed a few other things (HERMS coil, bulkheads, sight glasses etc) that we'll discuss along the way.

The purpose of this thread is to give some insight on time and effort and maybe some tricks (and hopefully not too many mistakes)

Here's a look at the "BEFORE" brewery. Hybrid Propane/elect. Keggle MT and BK with the electric water cooler HLT. Its worked great and made some good beer.

Without too much background, we recently moved into a new house, and of course one of my requirements was to have a dedicated brewing space...(to be honest, it was one of SWMBO's top requirements

)

)Our new house has a 10x16 building in back that the new brewery will be going into, but not before the new system gets built and ready to go.

So lets get to it!

Need to upgrade my existing 3 vessel hybrid system to all electric. I've been lusting after Kal's Electric Brewery for a long time, and pulled the trigger on the DIY kit. Needed a few other things (HERMS coil, bulkheads, sight glasses etc) that we'll discuss along the way.

The purpose of this thread is to give some insight on time and effort and maybe some tricks (and hopefully not too many mistakes)

Here's a look at the "BEFORE" brewery. Hybrid Propane/elect. Keggle MT and BK with the electric water cooler HLT. Its worked great and made some good beer.