CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

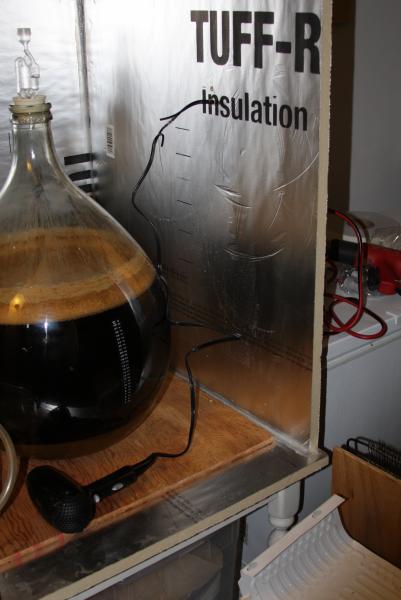

OK just started to gut my college refridge for a fermentation build. Plan is to take out the internals and use them in a double demi john fermentation chamber.

Amazing! I have an old college fridge that I want to do the same with. I may try to find cabinets on Craigslist to camouflage it tho. Did you use an off the shelf temperature controller? If so, did you get it locally? It seems to me that we live in the same county!

Also - since your are a syracusian, you interested in bulk grain? Just wanted to make sure you saw the thread for the bulk syracuse buys, saves you a ton of money on grain purchases. Let me know if you need more info.

I'm still extract brewing. I read the bulk grain posts (thats how I figured we are fellow Syracusians) but alas I don't know even where to begin with that huge PDF list!

I would like to transition to all grain in the next year or so. At that point, I hope to participate in the grain buys.

Enter your email address to join: