goatchze

Well-Known Member

What is the purpose of this recirculation? I understand the idea is to only need two vessels, however, I see a few big disadvantages:

1. Mixing the wort/sparge water over the grain bed will hurt efficiency

2. This system requires two pumps

3. You're supposed to recirculate until the gravity of the kettle/MLT are equal...seems like a lot of work and measuring.

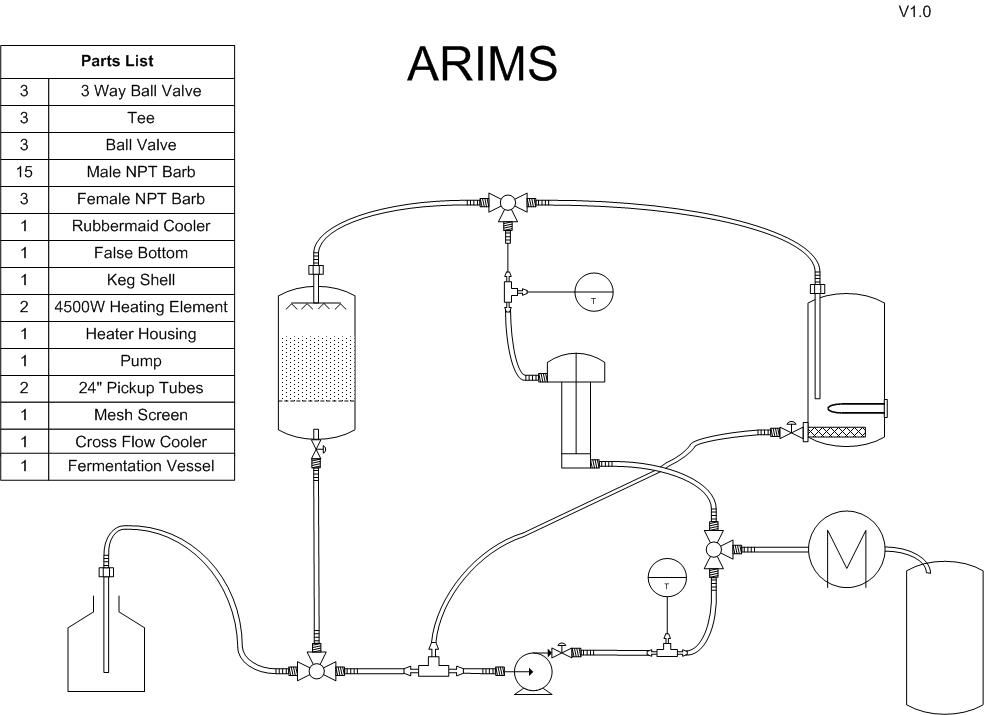

I've ordered all the parts and have my stand built, just waiting on delivery to complete my build. But I still don't understand why I don't see more systems like below. I want to make sure I'm not missing something.

This configuration

1. Only uses two vessels

2. Only uses one pump

3. Allows a sparge independent of the first wort

4. Allows the first wort to start heating/approaching boil during sparge (saves time)

In this system I plan to do everything as in the Brutus up until draining the MLT. It's different from then on. I'll drain the wort to the brew kettle and fire up the heating element. Fresh water will pass through the RIMS tube to heat up to sparge temps before entering the MLT, all while the first wort is being heated to a boil. The sparge water then gets pumped/added to the kettle. (BTW, that thing in the Riddle is the RIMS tube)

I'll have the option of either recirculating the sparge water or just doing a simple fill/drain batch sparge, throttling the pump to hit a target RIMS outlet temperature. I can also do more than one sparge if I choose. (I'll find out what works best after it's built).

What is everyone's thoughts?