sirsloop

Well-Known Member

Its time for my annual MONSTER BREW! Last year I made a souped up version of my Trois Pistoles, called Quad Pistoles. It was a bit over 11% after it was all said and done. Gold medal winner at SplitRock beer fest too! This year I'm on a new adventure in extreme brewing, tackling the 120 minute IPA. This is going to be like a 2+ month process to complete this brew.

Starter Starter.

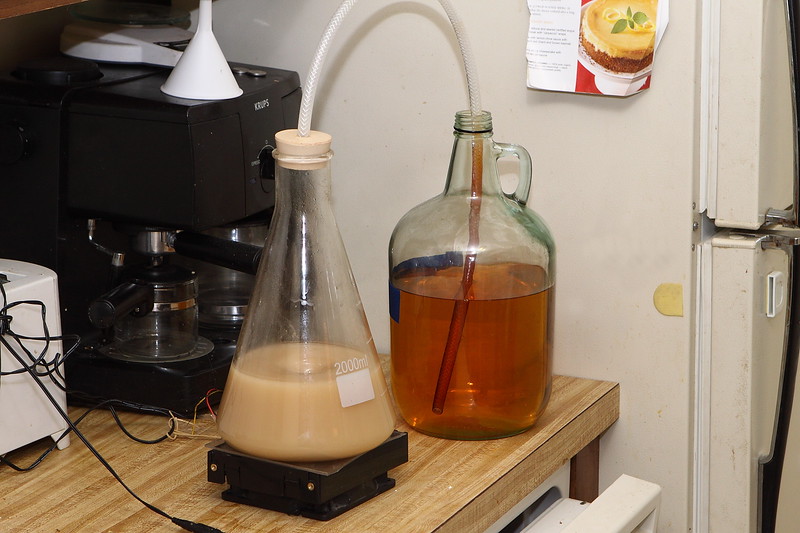

I cooked up a 1.2L 1.040 starter this evening for my WLP099 yeast. Its roughly 4oz if pale DME in 1.2L of water. Pitched, added some yeast nutrient and energizer, hit it with a healthy dose of O2, attached a blow off, and mounted it on my stirplate.

Monster Starter Ordinary Bitter.

The plan is to brew a 5 gallon ~1.040 Ordinary Bitter friday night to build up a nice fat yeast cake. Lessons learned from my 11+% batch, you need a S**T LOAD of yeast to finish the job dry enough. A pansy little starter isn't gonna hack it. The idea here is to brew a nice and easy batch of beer for the yeast so they can procreate with limited stress. I'll admit, I don't typically (ehh...never) brew anything "ordinary" unless its part of something "extraordinary". I used a Jamil recipe for this. Who knows, if its any good maybe I'll win something at an upcoming brew comp. Here's the recipe for this brew.

http://jdhaesloop.com/52 - Ordinary Bitter.pdf

MONSTERRRRRRRRRRRRRRR Brew!

Let the games begin! The brew goals here is a 1.200, 20+% ABV, IIPA. Why? Why not. I think the 120minute has an awesomely unique flavor and I wanna say I brewed one that big. Granted its not a session beer, but not many people can say they have pulled one off. It takes planning, care, and patience!

A couple notes about brewing a monster ale like this. Attenuation is my #1 goal in the brewing process. With a standard brew you can do 65-70% attenuation and achieve a great tasting brew. Well if you start at 1.200 you really cannot afford to hit only 70%. You'll end up with a 1.060 beer! That's enough left over sugar to completely make another pretty strong ale! The goal is at least 82% attenuation, but I bet I can get it closer to 85% over time considering how much dextrose this will have in it. The 11+% beer I did hit roughly 82% and it was all DME, and only a couple pounds of candi/lyles golden syrup. Here's the recipe for the 120min. Its a slight modification of a recipe a found online. Most of of its the same, hops are a little different, sugar additions, etc. IDK... I wouldn't have guessed 12 pounds of dextrose! HA!

http://jdhaesloop.com/53 - 120 Minute IPA.pdf

One big concern. I don't think I've ever had 17# worth of grain in my mash tun. I think the most I've ever had in there was like 14#. It'll be a damn tight fit in a 6.5 gal masher. I'll probably end up mashing around (or under) 1qt/lbs. I'm mashing for at least 90 minutes here to ensure complete conversion of all available sugars. I may let it go 120min for the hell of it. I'm mashing low to keep it dry, 149-151°F. Back to attenuation... more time I allow means more sugars are broken down. Ideally I would be able to fit a little more water in there, but this is what I have to work with. I'll double sparge it and drain out as much as possible. I'm guessing 75% efficiency. I'll be pulling out at least an extra gallons of water for the extra boil time.

Finishing at 20%+ ABV.

I read a number of threads and reviews about WLP099. A lot of people mentioned their difficulty in getting to 20% with this. A lot of people mentioned it puttered out at 12-14%. In all cases I noted one or more things they could have done extra to extend the life of their yeast. First thing is to make an easy-to-ferment starter and overpitch like crazy. In this case I'll be overpitching (23g) US-05 dry yeast, and like mentioned before, I'm using a 1.040 brew to build up excess numbers of the WLP099 for the finale.

Next you have to step your sugar additions. The grain alone is probably a little high... somewhere in the 90s for grain OG. You cannot expect yeast to be able to thrive in 1.200 wort, but they can take some sugars and a some alcohol at the same time. Add some of the sugars, ferment them, then add more. Give the yeast a chance to get hold and ferment in slightly easier conditions. Once the sugars in the grain bill are largely gone I'll pitch the WLP099 cake and start adding dextrose and oxygen.

Rouse the yeast often. Yeast buried in a cake are not fermenting! Slackers! Stir those SOB's up as often as possible early on and keep them working. Crack the whip. Once you have added all of the dextrose and fermentation seems to slow down you can lay off them. Until you near your FG, I will keep rousing them. It helps prevent stuck fermentation and will boost your attenuation %.

Nutrients are important when you start talking about extreme fermentation. We typically brew a batch of 1.050-1.070 beer, toss in some Nottinghams, and it magically ferments at 75% attenuation. In this case, the US-05 will have used up the oxygen in the brew through the grain bill. I'll add some more for the WLP099 to use for their ~100 point Odyssey. I don't want to continue adding oxygen to the end because it can lead to skunking during aging. I'm also going to be using Servomyces for the starter brew, the grain bill of the mega brew, and I'll add a cap when I pitch the WLP-099 in the IPA. I haven't used it before, but I don't see any con's listed on white labs website. In addition to that i'll probably add some Goferm when I rehydrate the US-05, and I'll be using Fermaid K during the mega brew. Keep the yeast happppy!

Temperature is pretty important. I wanted to choose a medium high temperature that's a compromise between full on crazy fermentation and limited fusel alcohol production. I think 70°F is a good temp to shoot for here. I fermented my 11% a little lower and it was great. I'm brewing this in the NJ winter. I use the distance to my sliding glass door to control temps. I measure by putting (and leaving) my thermometer under the fermenter. I can quickly turn it on and it should read pretty accurately what the core temp of the wort is. I think those sticky thermostats that go on the side can be effected by a few degrees by cold/hot air, especially through plastic.

So let see, mash low, add lots of 100% fermentable sugars like dextose post boil in steps, add nutrients when needed, add oxygen throughout the fermentation process, keep the yeast roused and working, and keep the temps in check. Anything I missed?

Anyways, I have the starter brewed for the starter starter. I plan on brewing the starter bitter friday. I'm gonna let that ferment and I'm flying to Miami until the 5th. I'll probably let the bitter ferment over that weekend and shoot for the big dog some night around the 9th-14th. Pics and updates to follow.

Starter Starter.

I cooked up a 1.2L 1.040 starter this evening for my WLP099 yeast. Its roughly 4oz if pale DME in 1.2L of water. Pitched, added some yeast nutrient and energizer, hit it with a healthy dose of O2, attached a blow off, and mounted it on my stirplate.

Monster Starter Ordinary Bitter.

The plan is to brew a 5 gallon ~1.040 Ordinary Bitter friday night to build up a nice fat yeast cake. Lessons learned from my 11+% batch, you need a S**T LOAD of yeast to finish the job dry enough. A pansy little starter isn't gonna hack it. The idea here is to brew a nice and easy batch of beer for the yeast so they can procreate with limited stress. I'll admit, I don't typically (ehh...never) brew anything "ordinary" unless its part of something "extraordinary". I used a Jamil recipe for this. Who knows, if its any good maybe I'll win something at an upcoming brew comp. Here's the recipe for this brew.

http://jdhaesloop.com/52 - Ordinary Bitter.pdf

MONSTERRRRRRRRRRRRRRR Brew!

Let the games begin! The brew goals here is a 1.200, 20+% ABV, IIPA. Why? Why not. I think the 120minute has an awesomely unique flavor and I wanna say I brewed one that big. Granted its not a session beer, but not many people can say they have pulled one off. It takes planning, care, and patience!

A couple notes about brewing a monster ale like this. Attenuation is my #1 goal in the brewing process. With a standard brew you can do 65-70% attenuation and achieve a great tasting brew. Well if you start at 1.200 you really cannot afford to hit only 70%. You'll end up with a 1.060 beer! That's enough left over sugar to completely make another pretty strong ale! The goal is at least 82% attenuation, but I bet I can get it closer to 85% over time considering how much dextrose this will have in it. The 11+% beer I did hit roughly 82% and it was all DME, and only a couple pounds of candi/lyles golden syrup. Here's the recipe for the 120min. Its a slight modification of a recipe a found online. Most of of its the same, hops are a little different, sugar additions, etc. IDK... I wouldn't have guessed 12 pounds of dextrose! HA!

http://jdhaesloop.com/53 - 120 Minute IPA.pdf

One big concern. I don't think I've ever had 17# worth of grain in my mash tun. I think the most I've ever had in there was like 14#. It'll be a damn tight fit in a 6.5 gal masher. I'll probably end up mashing around (or under) 1qt/lbs. I'm mashing for at least 90 minutes here to ensure complete conversion of all available sugars. I may let it go 120min for the hell of it. I'm mashing low to keep it dry, 149-151°F. Back to attenuation... more time I allow means more sugars are broken down. Ideally I would be able to fit a little more water in there, but this is what I have to work with. I'll double sparge it and drain out as much as possible. I'm guessing 75% efficiency. I'll be pulling out at least an extra gallons of water for the extra boil time.

Finishing at 20%+ ABV.

I read a number of threads and reviews about WLP099. A lot of people mentioned their difficulty in getting to 20% with this. A lot of people mentioned it puttered out at 12-14%. In all cases I noted one or more things they could have done extra to extend the life of their yeast. First thing is to make an easy-to-ferment starter and overpitch like crazy. In this case I'll be overpitching (23g) US-05 dry yeast, and like mentioned before, I'm using a 1.040 brew to build up excess numbers of the WLP099 for the finale.

Next you have to step your sugar additions. The grain alone is probably a little high... somewhere in the 90s for grain OG. You cannot expect yeast to be able to thrive in 1.200 wort, but they can take some sugars and a some alcohol at the same time. Add some of the sugars, ferment them, then add more. Give the yeast a chance to get hold and ferment in slightly easier conditions. Once the sugars in the grain bill are largely gone I'll pitch the WLP099 cake and start adding dextrose and oxygen.

Rouse the yeast often. Yeast buried in a cake are not fermenting! Slackers! Stir those SOB's up as often as possible early on and keep them working. Crack the whip. Once you have added all of the dextrose and fermentation seems to slow down you can lay off them. Until you near your FG, I will keep rousing them. It helps prevent stuck fermentation and will boost your attenuation %.

Nutrients are important when you start talking about extreme fermentation. We typically brew a batch of 1.050-1.070 beer, toss in some Nottinghams, and it magically ferments at 75% attenuation. In this case, the US-05 will have used up the oxygen in the brew through the grain bill. I'll add some more for the WLP099 to use for their ~100 point Odyssey. I don't want to continue adding oxygen to the end because it can lead to skunking during aging. I'm also going to be using Servomyces for the starter brew, the grain bill of the mega brew, and I'll add a cap when I pitch the WLP-099 in the IPA. I haven't used it before, but I don't see any con's listed on white labs website. In addition to that i'll probably add some Goferm when I rehydrate the US-05, and I'll be using Fermaid K during the mega brew. Keep the yeast happppy!

Temperature is pretty important. I wanted to choose a medium high temperature that's a compromise between full on crazy fermentation and limited fusel alcohol production. I think 70°F is a good temp to shoot for here. I fermented my 11% a little lower and it was great. I'm brewing this in the NJ winter. I use the distance to my sliding glass door to control temps. I measure by putting (and leaving) my thermometer under the fermenter. I can quickly turn it on and it should read pretty accurately what the core temp of the wort is. I think those sticky thermostats that go on the side can be effected by a few degrees by cold/hot air, especially through plastic.

So let see, mash low, add lots of 100% fermentable sugars like dextose post boil in steps, add nutrients when needed, add oxygen throughout the fermentation process, keep the yeast roused and working, and keep the temps in check. Anything I missed?

Anyways, I have the starter brewed for the starter starter. I plan on brewing the starter bitter friday. I'm gonna let that ferment and I'm flying to Miami until the 5th. I'll probably let the bitter ferment over that weekend and shoot for the big dog some night around the 9th-14th. Pics and updates to follow.

I figured I'd let the US-05 get stressed while chewing through the first 1.090 dose, then i'll add a nice and healthy cake of WLP099 to complete the dextrose fermentation. There's really no getting around stressing out the yeast in this brew. I fully intend on adding sugar until I either run out or the yeast stall (and I have a crap load of sugar).

I figured I'd let the US-05 get stressed while chewing through the first 1.090 dose, then i'll add a nice and healthy cake of WLP099 to complete the dextrose fermentation. There's really no getting around stressing out the yeast in this brew. I fully intend on adding sugar until I either run out or the yeast stall (and I have a crap load of sugar).