So I plan to use a sanke keg for a MT that I can direct fire. I will be recirculating the wort during heating of course.

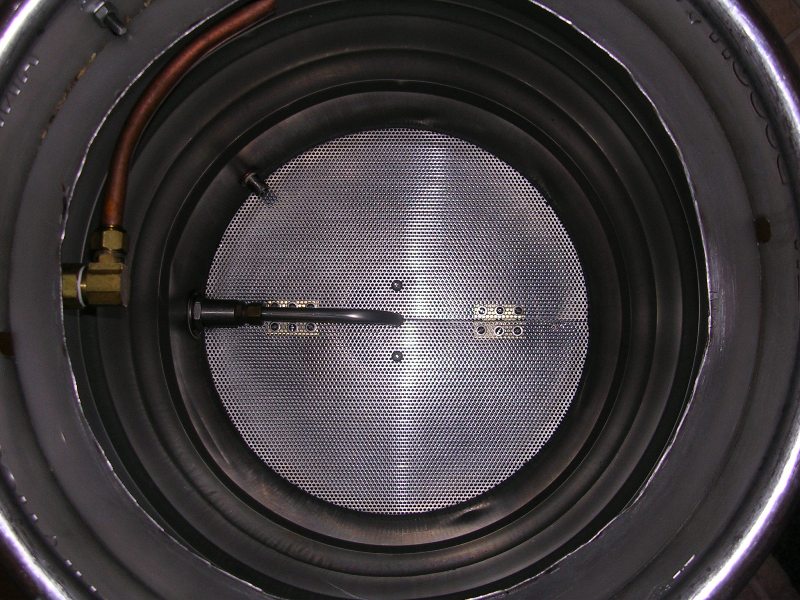

1) I plan on a false bottom too. How low can I put the false bottom so that I can still direct fire without worrying about scorching? I will have a diptube too, so no worry about dead space. But I don't want too much height to either, obviously.

I understand there's 1 gallon of liquid in the dimple of sankes. Can I have the false bottom just a tab above that or do I need more room for no scorching?

2) Also when recirculating to people just lay the hose over the opening and let it flow? I was thinking of adding a thermometer inline to the return line of the recirc tubbing so I know to not exceed 168 for the wort going back into the MT. Or is this a waste of time?

3) If I want to do step mashing, would I be able to heat the mash 20 degree or so in a reasonable amount of time without scorching wort or would this be very slow? I guess the same with raising to mashout from 150ish to 168. Will this be quick without scorching?

4) Lastly, what propane burner would you recommend that can go low enough without scorching, but still able to heat 6-7 gallons of strike water in decent time.

Thanks all.

Gregg

1) I plan on a false bottom too. How low can I put the false bottom so that I can still direct fire without worrying about scorching? I will have a diptube too, so no worry about dead space. But I don't want too much height to either, obviously.

I understand there's 1 gallon of liquid in the dimple of sankes. Can I have the false bottom just a tab above that or do I need more room for no scorching?

2) Also when recirculating to people just lay the hose over the opening and let it flow? I was thinking of adding a thermometer inline to the return line of the recirc tubbing so I know to not exceed 168 for the wort going back into the MT. Or is this a waste of time?

3) If I want to do step mashing, would I be able to heat the mash 20 degree or so in a reasonable amount of time without scorching wort or would this be very slow? I guess the same with raising to mashout from 150ish to 168. Will this be quick without scorching?

4) Lastly, what propane burner would you recommend that can go low enough without scorching, but still able to heat 6-7 gallons of strike water in decent time.

Thanks all.

Gregg