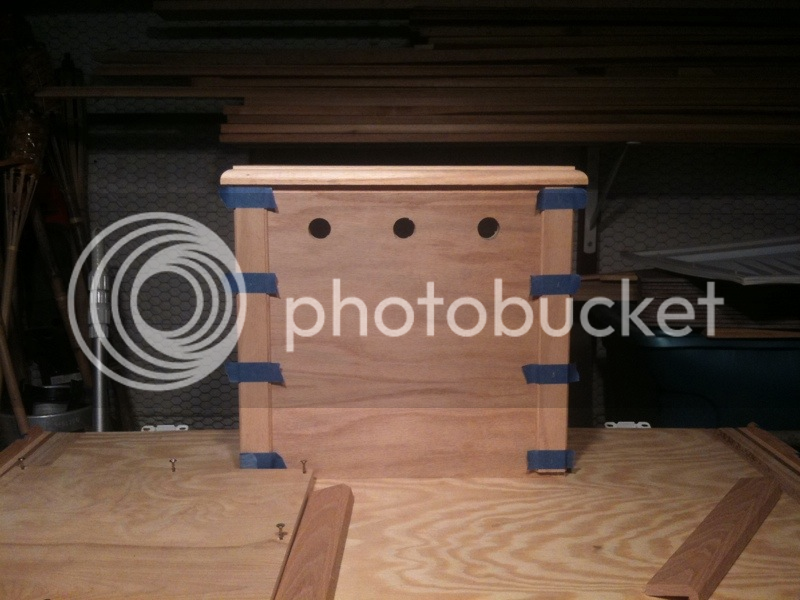

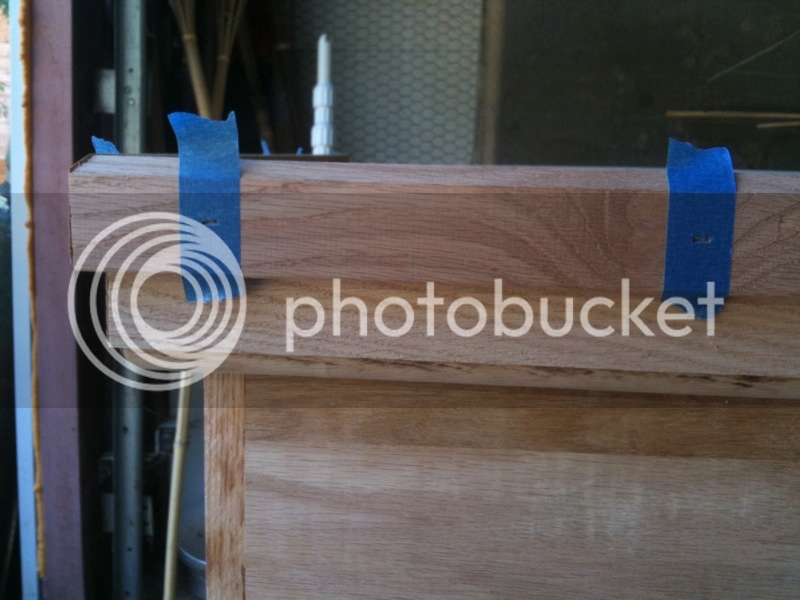

I am planning on an Irish coffin with 2 taps, and space in between for a third later on. Just got it started this weekend. Will update when I get to work on it some more.:rockin:

http://i204.photobucket.com/albums/bb292/okgasdude/336e0f44.png

http://i204.photobucket.com/albums/bb292/okgasdude/eba42e82.png

http://i204.photobucket.com/albums/bb292/okgasdude/42b8cedf.png

Edit: Almost forgot the best part, SWMBO got all the parts for me for my birthday!! I think she is almost as excited as I am to get my brew on tap!

http://i204.photobucket.com/albums/bb292/okgasdude/336e0f44.png

http://i204.photobucket.com/albums/bb292/okgasdude/eba42e82.png

http://i204.photobucket.com/albums/bb292/okgasdude/42b8cedf.png

Edit: Almost forgot the best part, SWMBO got all the parts for me for my birthday!! I think she is almost as excited as I am to get my brew on tap!

Man I cant wait to get this baby going!!!

Man I cant wait to get this baby going!!!