JeffoC6

Well-Known Member

I realize that buttered popcorn and cooked vegetables (cabbage) is a common off flavor in homebrewing. Everything I've read on it basically says it's due to yeast issues or sanitation.

After spending months getting my tannin issues under control (I think I finally figured it out), I'm now having issues with a buttery/slick/cabbage'y aftertaste in my brews.

I just opened my pumpkin ale which I brewed back in early August. It's actually REALLY good, save for the aftertaste of cabbage/butter that I'm getting.

I'm really quite OCD when it comes to sanitation, so I'm wondering what else I could be doing wrong?

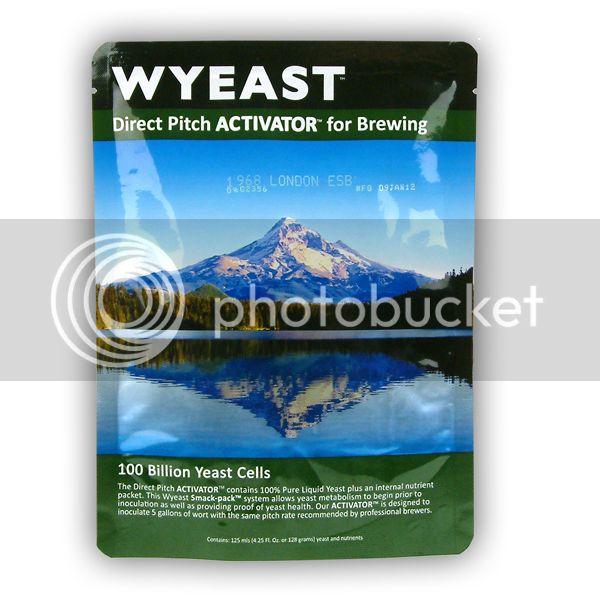

I brew 1 gallon batches, I don't use starters, and I usually pitch a little more yeast than Mr. Malty calls for (to be safe). I also primary only for 3 weeks minimum. I do not cold crash, and I bottle condition for 3 weeks minimum for medium gravity beers.

I have loads of details about my Pumpkin ale, so I'd be happy to share them and of course, offer any info on the processes I used, so please, help a brother out.

I should note that I experienced this same off flavor on one of the Bell's Two Hearted ale clones that I did back in July.

I feel like I've yet to make a beer that I've said "wow" too...and I've been brewing since January. I'm really starting to get discouraged, as for awhile it was overcarbonation, and then it was tannin extracting from too thin a mash, and now it's off flavors of cabbage and butter.

Please help

After spending months getting my tannin issues under control (I think I finally figured it out), I'm now having issues with a buttery/slick/cabbage'y aftertaste in my brews.

I just opened my pumpkin ale which I brewed back in early August. It's actually REALLY good, save for the aftertaste of cabbage/butter that I'm getting.

I'm really quite OCD when it comes to sanitation, so I'm wondering what else I could be doing wrong?

I brew 1 gallon batches, I don't use starters, and I usually pitch a little more yeast than Mr. Malty calls for (to be safe). I also primary only for 3 weeks minimum. I do not cold crash, and I bottle condition for 3 weeks minimum for medium gravity beers.

I have loads of details about my Pumpkin ale, so I'd be happy to share them and of course, offer any info on the processes I used, so please, help a brother out.

I should note that I experienced this same off flavor on one of the Bell's Two Hearted ale clones that I did back in July.

I feel like I've yet to make a beer that I've said "wow" too...and I've been brewing since January. I'm really starting to get discouraged, as for awhile it was overcarbonation, and then it was tannin extracting from too thin a mash, and now it's off flavors of cabbage and butter.

Please help