You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your sculpture or brew rig

- Thread starter Onescalerguy

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Has anyone checked out globalindustrial.com for the wesco mini-winch stacker? It's pricey but it's the only thing I've found to lift those heavy carboys. Haven't bought yet.

A friend of mine uses a small chainfall mounted to a track to lift kegs and carboys in his brew rig and keezer.

CastleHollow

Well-Known Member

Put this together last week out of some scrap pressure treated lumber and about $30 in plywood & other parts

Still needs a little work but I plan to take it out for a spin in the next few weeks

Still needs a little work but I plan to take it out for a spin in the next few weeks

My two tier rig. Immersion and counter flow chillers. Chugger pump hard wired to gfci switched outlet. Hard plumbed filtered lines for filling and cleanup. Chillers plumbed to stand. It works well but there is always something to be done

MaxOut

Well-Known Member

Here is a recent picture of my current setup. Pumping out 1BBL brews and still testing new styles and small brews on the original 10 gallon system. 60 Gallon BK, 40 Gallon MLT, Rinnai Instant HWH for HLT. I'm hooked on home brew for life!!

CoalCracker

Well-Known Member

CastleHollow

Well-Known Member

Damn, MaxOut  that's some serious "home"brewing gear--I'm thinking I ought to delete that picture of my embarrassing wooden ghettorig

that's some serious "home"brewing gear--I'm thinking I ought to delete that picture of my embarrassing wooden ghettorig

CoalCracker

Well-Known Member

Yea I thought my 1bbl was going to be big.

gyropilot1

Well-Known Member

insane is short!! maxoout you BK and mlt are gas burner or electric. I also saw some back lines to the 15 gal keg yu use them in the process? I will like to see the fermentators.

SmokeHavel

Member

Maxout- Those 15g keggles look so damn tiny in comparison. Do you have a dedicated brewhaus, garage, or basement? Nicely done.

MaxOut

Well-Known Member

gyropilot1 said:insane is short!! maxoout you BK and mlt are gas burner or electric. I also saw some back lines to the 15 gal keg yu use them in the process? I will like to see the fermentators.

Check my build thread in my signature. The 60 gallon BK is a propane fired steam kettle, the 40 gallon MLT is jacketed but heated indirectly by recirculating wort through the keggle heat exchanger in HLT and water in MLT jacket is circulated through the keggle BK. Both the Bk & HLT keggles are directly fired by BCS controlled BG14 propane burners. I also use the keggles to temper and measure water from instant hot water heater for strike and sparge.

MaxOut

Well-Known Member

SmokeHavel said:Maxout- Those 15g keggles look so damn tiny in comparison. Do you have a dedicated brewhaus, garage, or basement? Nicely done.

Yes, I donated a big part of my garage to the brewery. The Brewstation is way too heavy to move around. I have water and propane piped to the Rinnia tankless water heater, Brewstation and kettles. Check out my build thread in my signature.

Well done all! ALL of them look GREAT and will make fantastic brew!

galaxyjump

New Member

Modded Costco stand. Cheers!

jeepinjeepin

Well-Known Member

I've made upgrades but I still can't call it a stand.

Rcole

Well-Known Member

Well, I have posted this elsewhere, but I guess it is time to make it official. This is my 20 gallon single tier, Brutus inspired stand. It is a natural gas, direct fired RIMS controlled by a pair of Blichmann Tower of Power units. Will be trying out the Blichmann LINK software on the next batch. The controllers are mounted on a CRT TV articulating mount.

I have only gotten a chance to use it twice because we just had a baby. But it works great. Took me about a year of building in my free time. I should also add that the dog is just drinking freshwater out of the brew kettle. Everything was cleaned and sanitized after that.

Hey VonMule what is that "thing" (long black tube) behind the dog/kettle? Some kind of chiller? heat exchange?

A year back or so, two of my co workers and I decided to go a bit bigger than our homebrewing systems.

Now our new "sculpture" is produced and November 15 it will be on a ship to Sweden where we have started a new microbrewery.

We do have some more pictures on our facebook page (language is Swedish but the pictures speak their own language)

http://www.facebook.com/Brygghus19

Now our new "sculpture" is produced and November 15 it will be on a ship to Sweden where we have started a new microbrewery.

We do have some more pictures on our facebook page (language is Swedish but the pictures speak their own language)

http://www.facebook.com/Brygghus19

Flash boiler. It produces all of the hot water and steam. It gives me hot water for strike and sparge, and it gives me steam for step mashing and boiling. Can't take credit though, I borrowed the idea from Kladue and Greenmonti. The tube is actually a quarter inch thick steel pipe, that i picked up form a pipe supplier for 12 bucks, that sucker is heavy considering the weight of the pipe and the 100 ft of copper inside it

A year back or so, two of my co workers and I decided to go a bit bigger than our homebrewing systems.

Now our new "sculpture" is produced and November 15 it will be on a ship to Sweden where we have started a new microbrewery.

We do have some more pictures on our facebook page (language is Swedish but the pictures speak their own language)

http://www.facebook.com/Brygghus19

Hahaha, good to see the Chiness factory is keeping up with it's H&S!

Looks nice! what size is it, 20hL? Who are you getting to fabricate it and how are they to deal with?

Good luck!

Jimmy_B

Well-Known Member

This is my BIAB setup that I mash in a cooler. I was aiming for something compact and easy to clean. I pump strike water from the pot to the cooler then gravity feed my runnings to the kettle (with the bag still in the cooler - no lifting involved). I don't bother with a mashout or sparge as I can hit 78% mash efficiency without either. The stand collapses and sets up in about 20 seconds.

SouthernBrew

Member

This setup is getting kinda old now. I want to weld up an all stainless single level that is fully automated. I have too many hobbies for this change to happen at any reasonable amount of time.

(don't know why this was flipped on it's side!)

(don't know why this was flipped on it's side!)

CoalCracker

Well-Known Member

Here is my work in progress. You can follow my blog to see more.

texashomer

Active Member

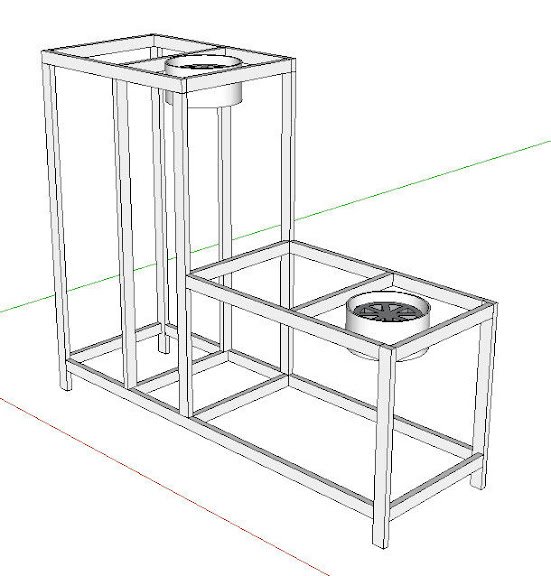

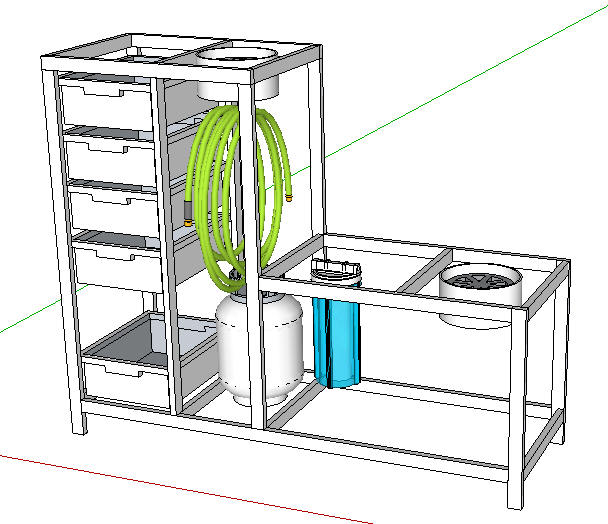

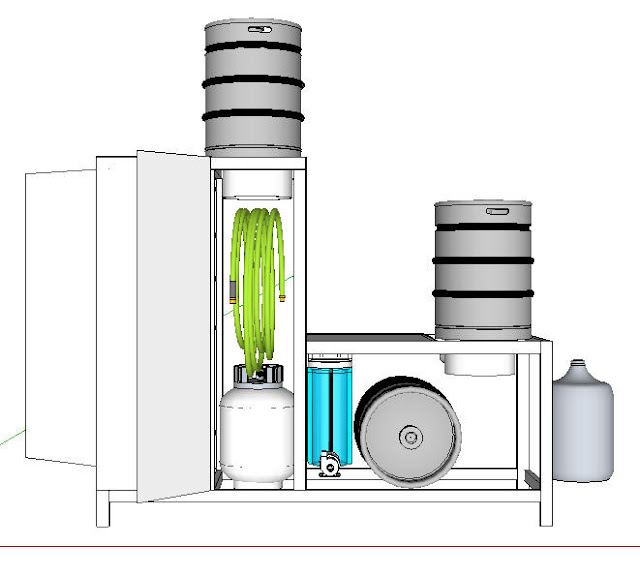

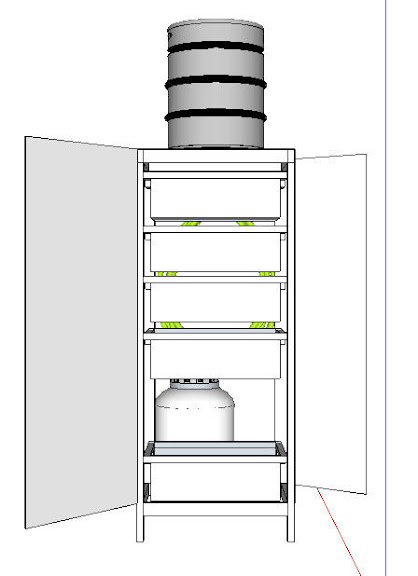

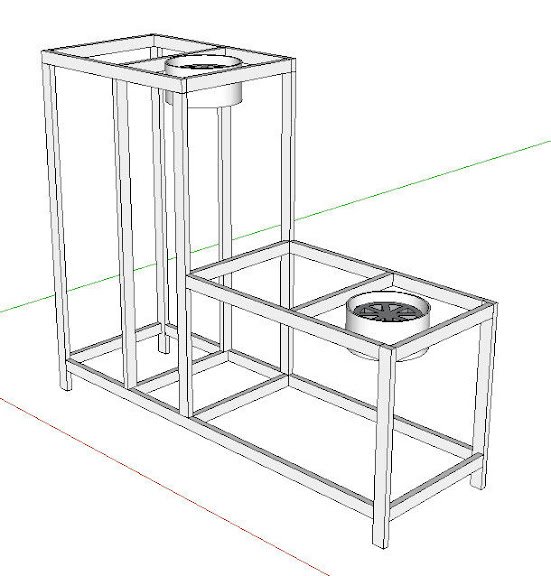

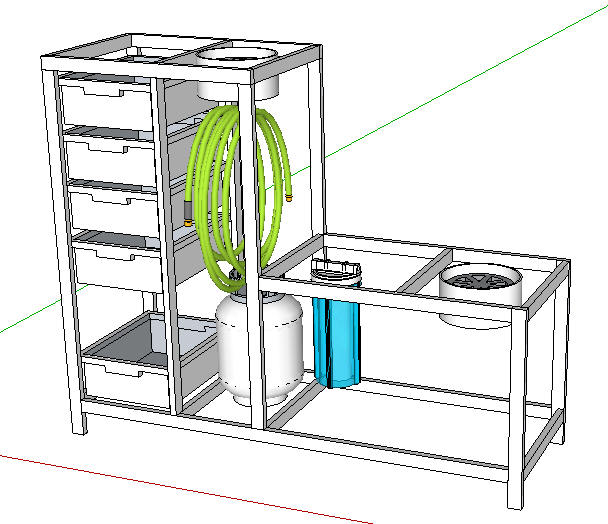

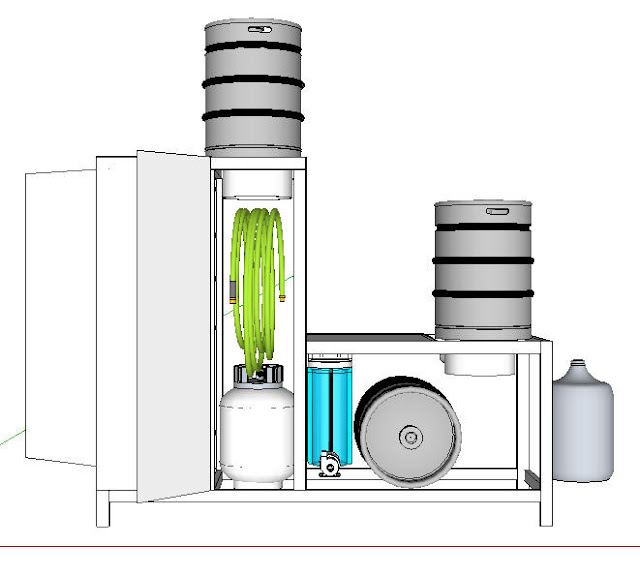

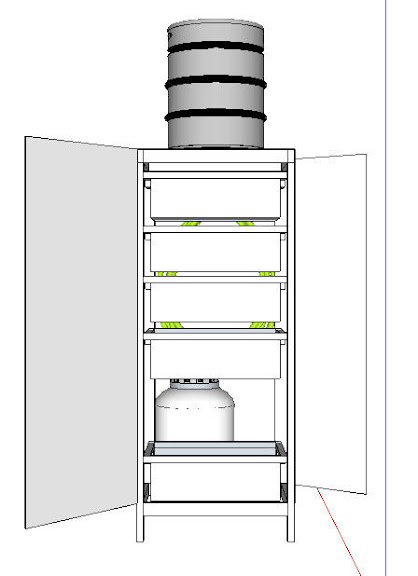

I've been trying to figure out the best setup for my enviroment. I'd really like to keep everything together so I can just wheel out to the driveway and start brewing. I plan on using one or two pumps to move liquid around and have only added the higher tier for storage. The length is 6'. The upper tier is 5', the lower being 3'. The width is 2'. The HLT will be up top, the boil kettle on the other side, and the MLT in the middle. I setup an outdoor kitchen when I brew so the Bus Tubs and Hose shown will be in use when the HTL is under flame.

I'd love any feedback or comments.

I'd love any feedback or comments.

If it were me, I'd put the storage into another cabinet on rollers I'd make it a single tier set up. You are going to have the pumps anyway.

If you go natural gas instead of propane you won't need to store a propane tank (or two).

If you go natural gas instead of propane you won't need to store a propane tank (or two).

slakwhere

Well-Known Member

don't forget to account for the height of the casters if you're really wheeling it out in the driveway.

SouthernBrew

Member

Here is my work in progress. You can follow my blog to see more.

Should that "Boil Temp" label be "Mash Temp"? I monitor HLT and mash temps but not the boil kettle.

CoalCracker

Well-Known Member

No, I will be controlling the boil and the HLT. The temp of the HLT will be the Mash temp since it is HERMS.

SS_Brewing_Co

Well-Known Member

- Joined

- Nov 18, 2011

- Messages

- 116

- Reaction score

- 5

brewman ! said:If it were me, I'd put the storage into another cabinet on rollers I'd make it a single tier set up. You are going to have the pumps anyway.

+1 to that.

BraxtonBrewery

Well-Known Member

- Joined

- Sep 6, 2008

- Messages

- 104

- Reaction score

- 7

Here is my work in progress. I've just recently finished it. I'm working on the control panel currently. Also the grain mill station.

Here is the build link:

https://www.homebrewtalk.com/f51/brewtius-maximus-braxton-10-complete-single-tier-build-352087/

Here is the build link:

https://www.homebrewtalk.com/f51/brewtius-maximus-braxton-10-complete-single-tier-build-352087/

revco

Well-Known Member

I can finally join this club! I'm on the path to building a semi-automated single tier Brutus style system, but had to get the big $$$ out of the way with my kettles, pumps, accessories, fittings and such. For now, I'm just on 2x6's...but the stand will come once I recover financially from everything in this phase, probably in a couple months.

I brewed on it last Sunday and all I can say is...it was awesome.

I brewed on it last Sunday and all I can say is...it was awesome.

SkullStacheBrew

Member

- Joined

- Nov 7, 2012

- Messages

- 5

- Reaction score

- 6

First time posting and I have to give a lot of credit to this thread. A lot of my ideas and plans came from all the different sculptures on here.

I will eventually get a rolling, single tiered system like a lot of you have, but I simply do not have the room yet. I was lucky enough to have room for a storage shed to put everything in. I used to pull everything out and set it up on chairs but decided just to mount everything inside the shed instead.

Check it out!

Open the doors and....

System contains two March pumps, a RIMS tube, keggle and burner, Rubbermaid mash tun and a separate Rubbermaid cooler for storing sparge water. Everything is controlled by a simple panel mounted on the inside with two PID controllers, one for the RIMS and one to display keggle temp.

Pull out the burner and you're ready to go!

Pumps are more or less permanently attached but the RIMS tube can be removed to drain.

Also features a ~30' counterflow wort chiller and a rack to hang up all my tubing on the door. Cheers!

http://skullstachebrew.blogspot.com/

I will eventually get a rolling, single tiered system like a lot of you have, but I simply do not have the room yet. I was lucky enough to have room for a storage shed to put everything in. I used to pull everything out and set it up on chairs but decided just to mount everything inside the shed instead.

Check it out!

Open the doors and....

System contains two March pumps, a RIMS tube, keggle and burner, Rubbermaid mash tun and a separate Rubbermaid cooler for storing sparge water. Everything is controlled by a simple panel mounted on the inside with two PID controllers, one for the RIMS and one to display keggle temp.

Pull out the burner and you're ready to go!

Pumps are more or less permanently attached but the RIMS tube can be removed to drain.

Also features a ~30' counterflow wort chiller and a rack to hang up all my tubing on the door. Cheers!

http://skullstachebrew.blogspot.com/

-TH-

Well-Known Member

^^^ Pretty dang clever. VERY well done!

Similar threads

- Replies

- 4

- Views

- 696

- Replies

- 2

- Views

- 1K